Catalytic system for Beckmann rearrangement of oxime

A Beckmann rearrangement and catalytic system technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, organic chemistry, etc. It can achieve the effect of realizing recycling, simple reaction system and high conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below by specific examples.

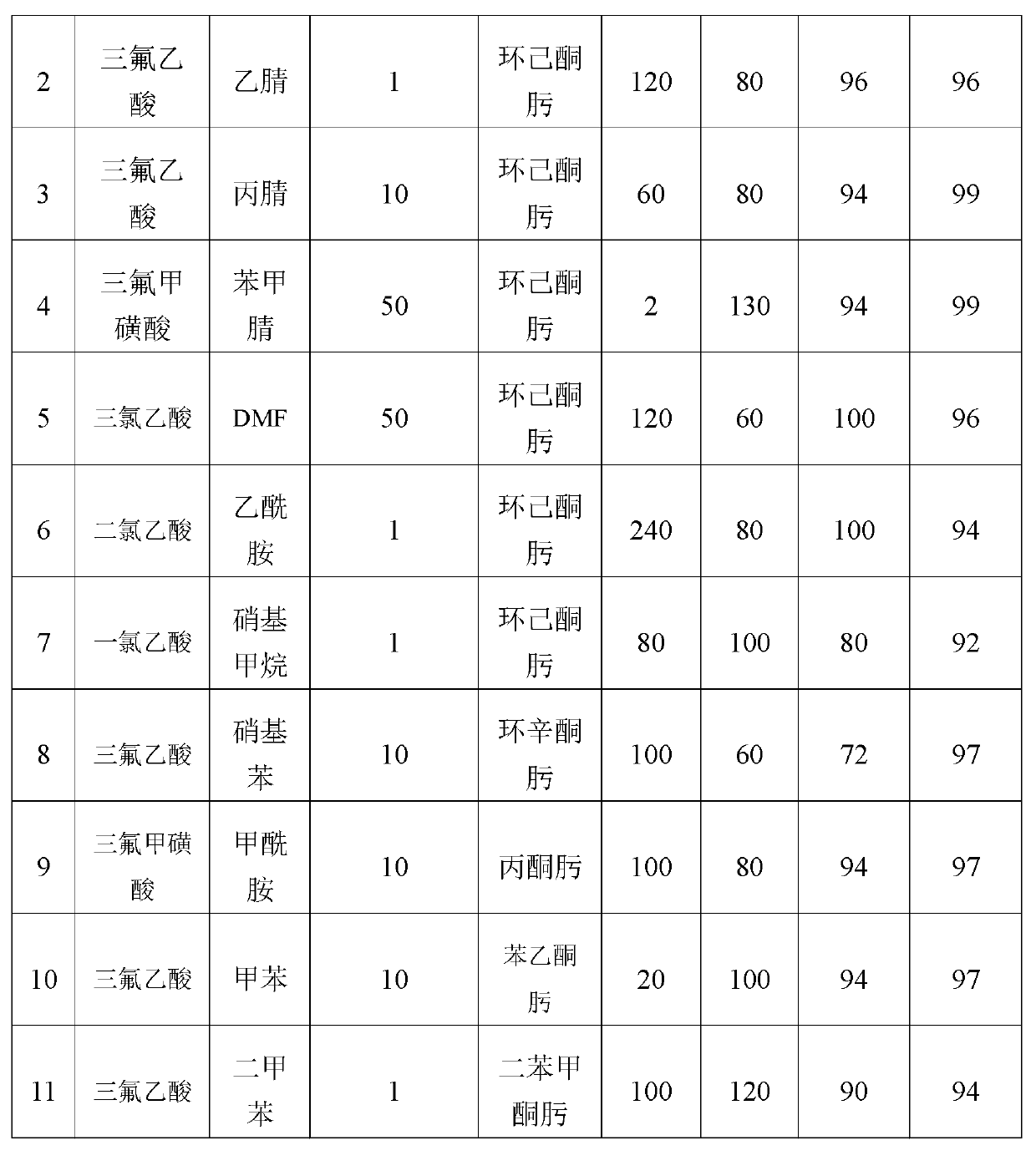

[0012] The experimental steps for the catalytic system to be used in the Beckmann rearrangement reaction of ketoxime are: add a certain amount of organic acid and 10 mmol of organic solvent into a three-necked flask, then add 2 mmol of ketoxime, control the temperature in an oil bath, and stir with a magnetic force. After a certain period of time, the product was analyzed to obtain the conversion rate of ketoxime and the selectivity of amide.

[0013] Embodiment 1-11 is carried out according to the above-mentioned experimental procedure, wherein the mol ratio of organic acid, organic solvent, organic acid and organic solvent, ketoxime, reaction time, reaction temperature, conversion rate of ketoxime after reaction finishes and amide The options are listed in Table 1.

[0014] Table 1 The raw materials and results of the preparation of amides from ketoximes via Beckmann rearrangement

[0015]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com