Center boiler remote monitoring system and control method thereof

A remote monitoring system and centralized technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of operating costs, decentralized maintenance costs of boiler control sites, etc., and achieve the effect of improving processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

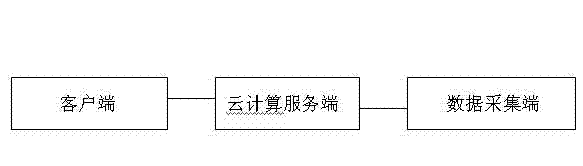

[0031] The technical solution is as follows: the boiler control system includes a client, a server terminal, and a data acquisition end, the server terminal is connected to the client and the data acquisition end, the data acquisition end includes a sensor and a CPU, and the server terminal is set as a cloud computing terminal. An encryption and decryption module is set between the client and the cloud computing terminal, and an encryption and decryption module is set between the data acquisition terminal and the cloud computing terminal. The encryption and decryption module sets two levels of encryption and decryption, the first is hash algorithm encryption, and then the DES algorithm encryption. The cloud computing terminal, the client and the data collection terminal are set to be wired or wirelessly connected. The implementation process is as follows: the sensor at the data collection end collects operating parameters and status data; encrypts the data and sends it to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com