Y-shaped agitating pile drilling machine

A technology of mixing pile drilling rig and drill pipe, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of unsatisfactory bearing capacity and single pile body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

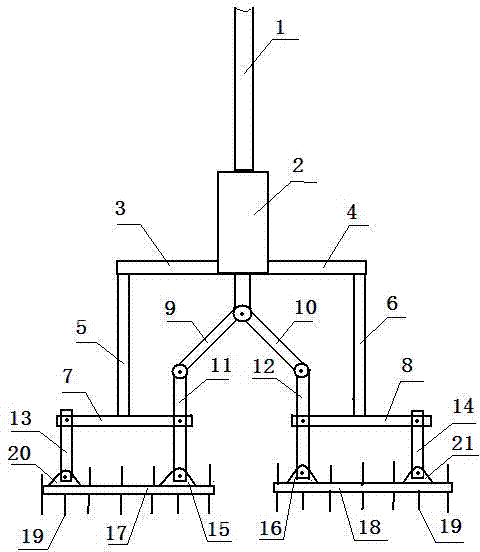

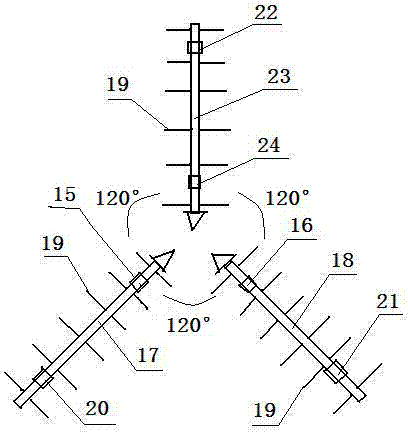

[0012] The accompanying drawing is a specific embodiment of the present invention, in which the upper end of the telescopic oil top 2 is fixed on the drill pipe 1, and the lower part of the telescopic oil top is evenly distributed on the upper cross bar A3, the upper cross bar B4, and the upper cross bar at an angle of 120°. C; The upper end of the vertical rod A5 is fixed to the upper cross rod A, the lower end is fixed to the middle of the lower cross rod A7, the upper end of the short swing rod A13 is hinged to the left end of the lower cross rod A, the lower end of the short swing rod A is hinged to the rear support A20, and the rear support A is fixed to the left end of the moving rod A; the upper end of the vertical rod B6 is fixed to the upper cross bar B, the lower end is fixed to the middle of the lower cross bar B8, the upper end of the short swing rod B14 is hinged to the right end of the lower cross rod B, and the lower end of the short swing rod B is hinged to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com