Full-oxygen humidifying and blasting device and technology for blast furnace

A technology of humidification blast and oxygen supply device, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc. It can solve the problems of easy burnout of oxygen coal guns and tuyere, high combustion temperature of oxygen blast furnace tuyere, and improve the reduction reaction in the furnace , prevent burnout, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

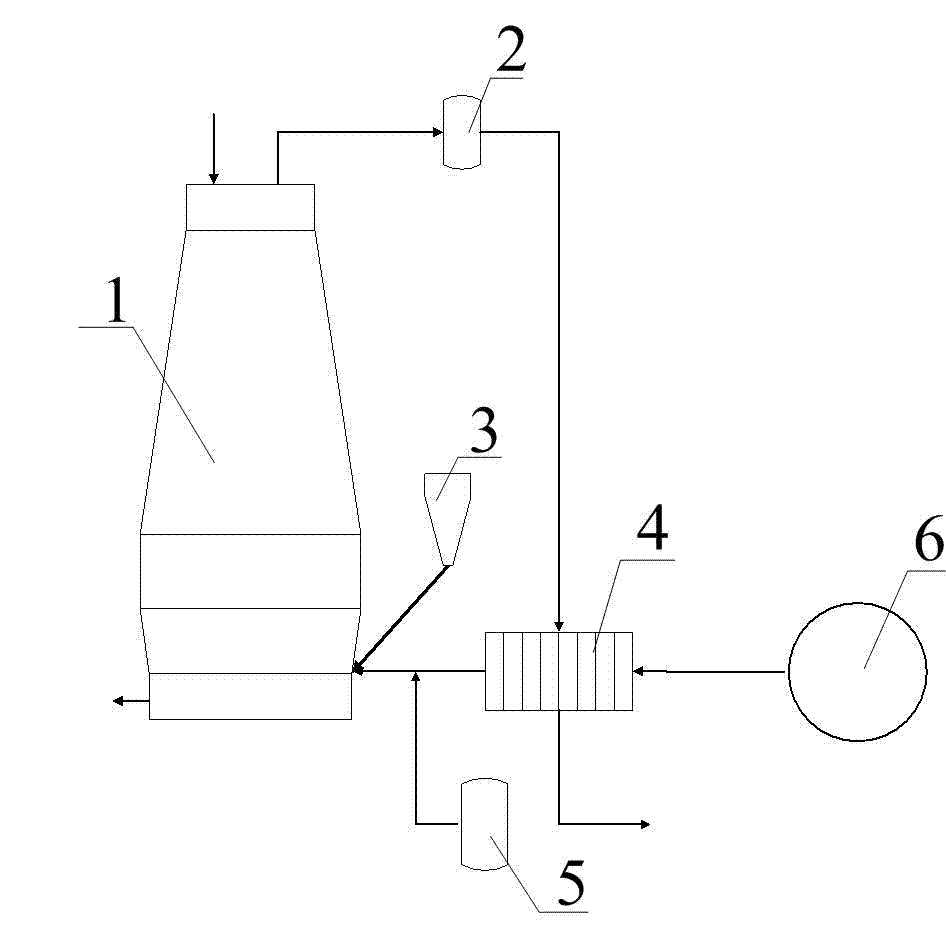

Image

Examples

Embodiment 1

[0014] This embodiment uses 1000m 3 Blast furnaces use pellets and sinter as raw materials. The technical indicators of production are: coke ratio: 250Kg / tHM; coal ratio: 330Kg / tHM; furnace top gas volume: 850Nm 3 / tHM, the heat-resistant temperature of the selected tuyere and oxygen coal gun is 2250°C.

[0015] This embodiment provides an all-oxygen blast furnace humidification blast process, which adopts the following steps:

[0016] 1) Add sinter, pellets and coke to the blast furnace from the top of the furnace in batches;

[0017] 2) A mixture of oxygen and steam is blown into the blast furnace, the temperature of oxygen blowing is 100°C, the volume purity of oxygen is 95%, and the amount of oxygen blowing is 320Nm 3 / tHM, the humidity of the mixture is 18%;

[0018] 3) Spray coal powder into the furnace.

[0019] The humidity of the mixture is mainly adjusted according to the oxygen temperature, the theoretical combustion temperature of the tuyere area of the blas...

Embodiment 2

[0023] This embodiment adopts 3000m 3 Blast furnaces use pellets and sinter as raw materials. The technical indicators of production are: coke ratio: 240Kg / tHM; coal ratio: 350Kg / tHM; furnace top gas volume: 840Nm 3 / tHM, the heat-resistant temperature of the selected tuyere and oxygen coal gun is 2400°C.

[0024] This embodiment provides an all-oxygen blast furnace humidification blast process, which adopts the following steps:

[0025] 1) Add sinter, pellets and coke to the blast furnace from the top of the furnace in batches;

[0026] 2) A mixture of oxygen and steam is blown into the blast furnace, the temperature of oxygen blowing is 130°C, the volume purity of oxygen is 90%, and the amount of oxygen blowing is 300Nm 3 / tHM, the humidity of the mixture is 15%;

[0027] 3) Spray coal powder into the furnace.

[0028] After adopting the process of this embodiment, the theoretical combustion temperature of the tuyere is about 2325°C, which is within the heat-resistant t...

Embodiment 3

[0030] This embodiment adopts 5000m 3 Blast furnaces use pellets and sinter as raw materials. Production technical indicators are: coke ratio: 190Kg / tHM; coal ratio: 370Kg / tHM; top gas volume: 820Nm 3 / tHM, the heat-resistant temperature of the selected tuyere and oxygen coal gun is 2450°C.

[0031] This embodiment provides an all-oxygen blast furnace humidification blast process, which adopts the following steps:

[0032] 1) Add sinter, pellets and coke to the blast furnace from the top of the furnace in batches;

[0033] 2) A mixture of oxygen and steam is blown into the blast furnace, the temperature of oxygen blowing is 650°C, the volume purity of oxygen is 80%, and the amount of oxygen blowing is 290Nm 3 / tHM, the humidity of the mixture is 13%;

[0034] 3) Spray coal powder into the furnace.

[0035] After adopting the process of this embodiment, the theoretical combustion temperature of the tuyere is about 2415°C, which is within the heat-resistant temperature rang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com