Preparation method of waterborne polyester resin used in coil coatings and application thereof

A water-based polyester resin and coil coating technology, which is applied in the preparation of water-based polyester resin, coatings, and the manufacture of coil coatings with low organic solvent content, to achieve the effects of reducing environmental pollution, saving energy, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The raw material components and proportions used in the preparation of water-based polyester resins are shown in Table 1.

[0026] Table 1

[0027]

[0028]

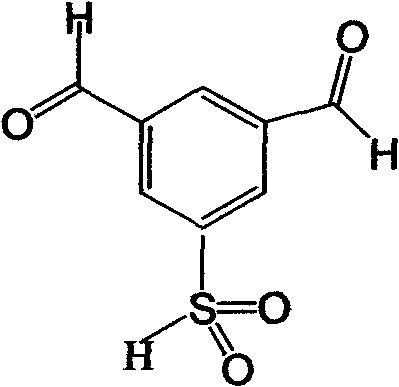

[0029] Add neopentyl glycol and isophthalic acid-5-sodium sulfonate in a 1000ml three-necked flask equipped with a stirrer, a reflux condenser, and a thermometer. Slowly heat under continuous stirring, add catalyst butyltin triisooctoate after the reactants are dissolved, raise the temperature of the reaction mixture to 200°C and keep it for 3 hours, then lower the temperature to 100°C, add other raw materials, slowly raise the temperature to 200°C, and keep the temperature for 5 hours ; When the acid value reaches below 15mgKOH / g, cool down to 150°C, add glycidyl tertiary carbonate, and keep warm for 4 hours. Add solvent and water to obtain water-based polyester. According to the national standard measurement, what is obtained is a transparent water-based polyester resin with a solid content of 55% and a v...

Embodiment 2

[0031] The preparation process and other formulations are the same as in Example 1 except that the isophthalic acid in the formulation is converted into an equivalent amount of hexahydrophthalic anhydride. The obtained product is a transparent water-based polyester resin with a solid content of 55% and a viscosity of 3450 centipoise according to the national standard.

Embodiment 3

[0033] Except that part of the isophthalic acid-5-sodium sulfonate in the formula is converted into an equivalent amount of isophthalic acid, the preparation process and other formulas are the same as in Example 1. The obtained product is a blue light water-based polyester resin with a solid content of 55% and a viscosity of 677 centipoise according to the national standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com