Filling and consolidating powder for mining purposes and use thereof

A technology for consolidating powder and mining, which is applied in the fields of backfill, mining equipment, earth-moving drilling, etc. It can solve the problems of difficult to meet the underground filling, poor fluidity of the mixture, and inability to exert the cement, and achieves good roof control effect and early strength. Good effect of high and surrounding rock support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The proportioning (weight) of each component in the consolidated powder of the present invention is:

[0034] Cement clinker 4%; Metakaolin 9%; Carbide slag 8%; Phosphogypsum 22%; Fly ash 20%; Red mud 12%; Blast furnace slag 16.5%; Limestone 7%; Water reducer 1%; Sodium hydroxide 0.5%.

[0035] The production method is to accurately weigh cement clinker, blast furnace slag and limestone in proportion, put them into a ball mill and grind them to a fineness of 300 mesh, then weigh the rest of the materials accurately in proportion and put them into a ball mill to grind them to a fineness of 400-400 mesh. 600 mesh is enough.

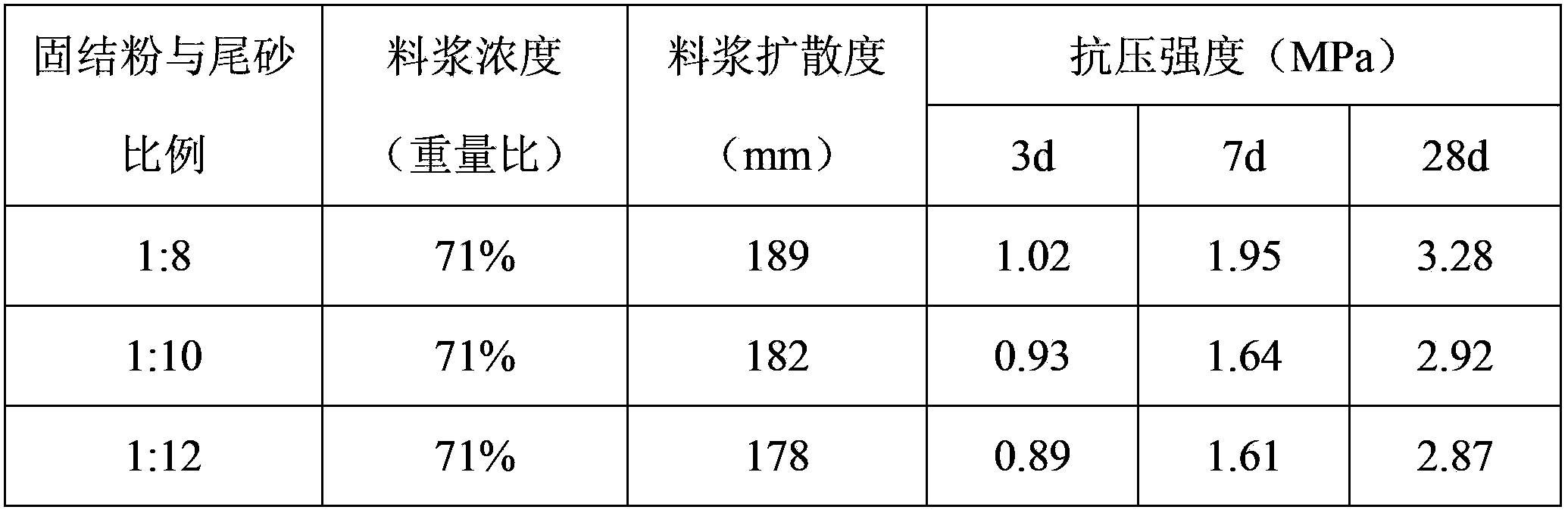

[0036] When preparing filling slurry, first mix the mining tailings and water in proportion to form a uniform slurry, then add consolidation powder, the ratio of consolidation powder to tailings is 1: (6-12), and the concentration of the slurry is controlled at 60 % to 80%, after mixing evenly in the mixer, the slurry can be transported downhole th...

Embodiment 2

[0041] The proportioning (weight) of each component in the consolidated powder of the present invention is:

[0042] Cement clinker 5%; Metakaolin 10%; Carbide slag 6%; Phosphogypsum 24%; Fly ash 19%; Red mud 9%; Blast furnace slag 18.5%; Limestone 7%; Water reducing agent 1%, Sodium hydroxide 0.5%.

[0043] See Example 1 for the production method and filling material preparation method of Example 2, and will not be described in detail here.

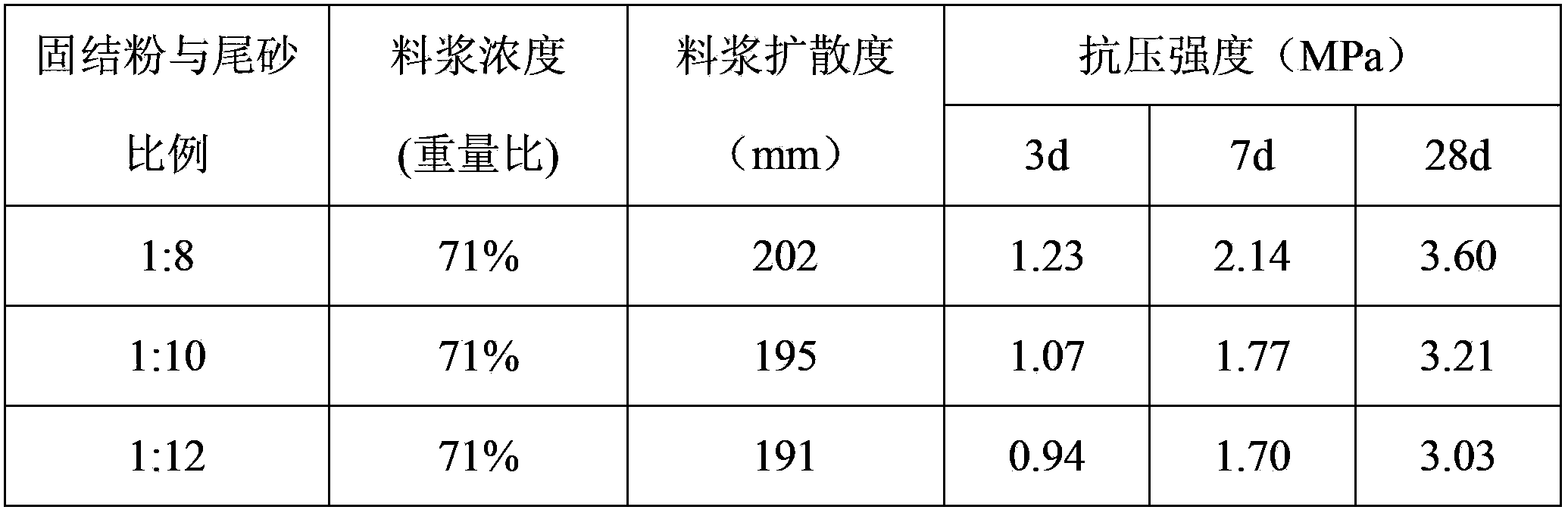

[0044] The following table 2 shows the test results of the physical properties of the metal mine filling material formed by mixing the consolidation powder and tailings in Example 2 in three weight ratios of 1:8, 1:10, and 1:12.

[0045] Table II

[0046]

Embodiment 3

[0048] The proportioning (weight) of each component in the consolidated powder of the present invention is:

[0049] Cement clinker 3%; Metakaolin 9%; Carbide slag 14%; Phosphogypsum 20%; Fly ash 18%; Red mud 12%; Blast furnace slag 18.3%; Limestone 4%; Water reducing agent 1%, Sodium hydroxide 0.7%.

[0050] The preparation method is to accurately weigh cement clinker, blast furnace slag and limestone in proportion, put them into a ball mill and grind them to a fineness of 300 mesh, then weigh the rest of the materials accurately in proportion and put them into a ball mill to grind them to a fineness of 400- 600 mesh is enough.

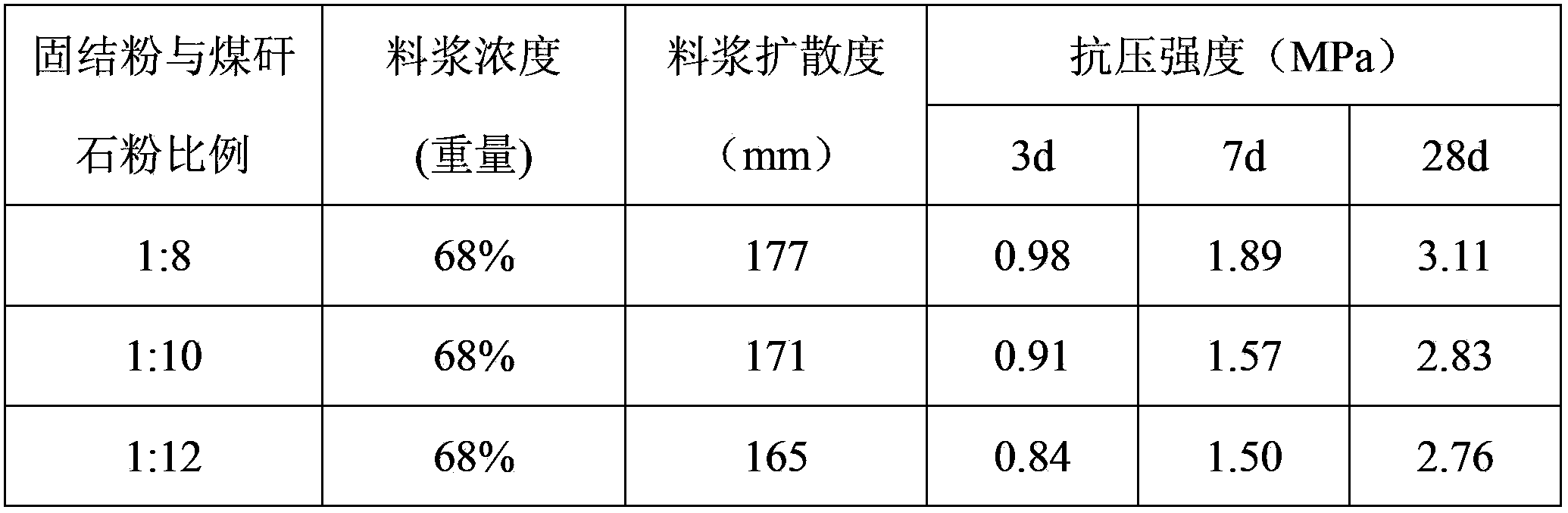

[0051] When preparing coal mine filling slurry, the coal gangue is first crushed to an average particle size of 1.5mm, and the maximum particle size is not allowed to exceed 5mm, and the coal gangue powder and water are mixed in proportion to form a uniform slurry, and then the consolidation powder is added to solidify. The ratio of coal powder to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com