Nano aeration biofilm reactor

A technology of biofilm reactor and nano-aeration, which is applied in the field of nano-filled biofilm reactor and nano-aeration. Ammonia nitrogen, energy waste and other issues, to achieve the effect of improving oxygen mass transfer capacity and dissolved oxygen concentration, improving the low utilization rate of oxygen, and reducing energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

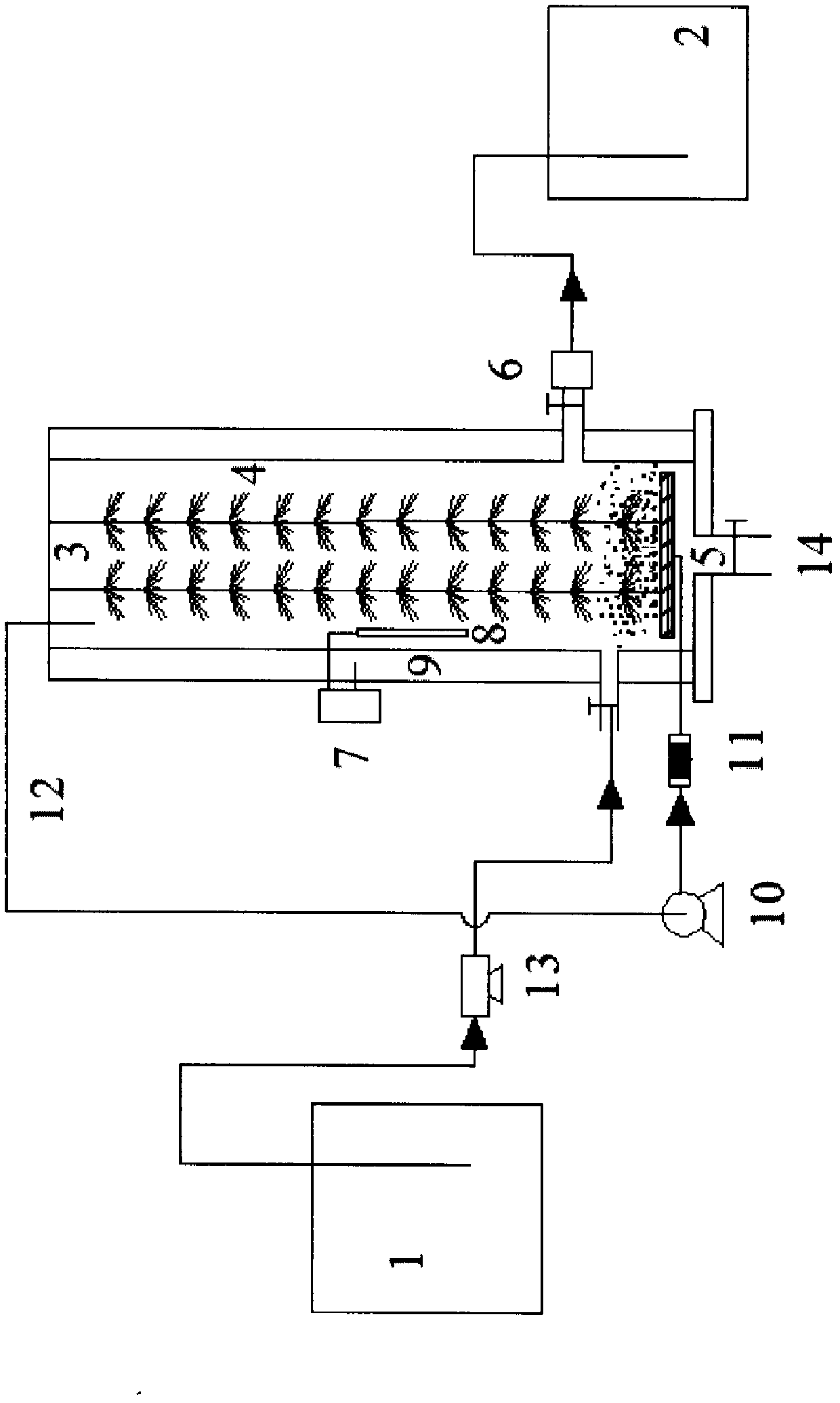

[0021] The entire nano aerated biofilm reactor of the present invention mainly includes five parts: a water inlet system, a reaction tank, a water outlet system, a heating system and an air supply system.

[0022] 1) Water intake system: composed of a water intake adjustment tank 1, a water pump 13 and a water intake pipeline. The sewage to be treated is stored in the water distribution tank of the water inlet regulating tank 1 , and the sewage is pumped into the reactor 3 by the water pump 13 . The opening and closing of the water pump 13 is controlled by a microcomputer (not shown).

[0023] 2) Reactor: composed of a reactor 3 and a filler 4 therein. Fillers are evenly placed in the reactor to allow the biofilm to grow on the filler; the filler 4 is made of nano-scale filler carbon fiber or combined filler, and the arrangement method is up and down, so that the reactor is not easy to be blocked.

[0024] 3) Water outlet system: it consists of a water outlet pool 2 and an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com