Novel machine tool bed casting assembly

A technology of machine tool and bed, which is applied in the field of casting assembly of new machine tool bed, can solve the problems of easy wear of guide rail, poor impact resistance, unsuitability for heavy-duty processing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

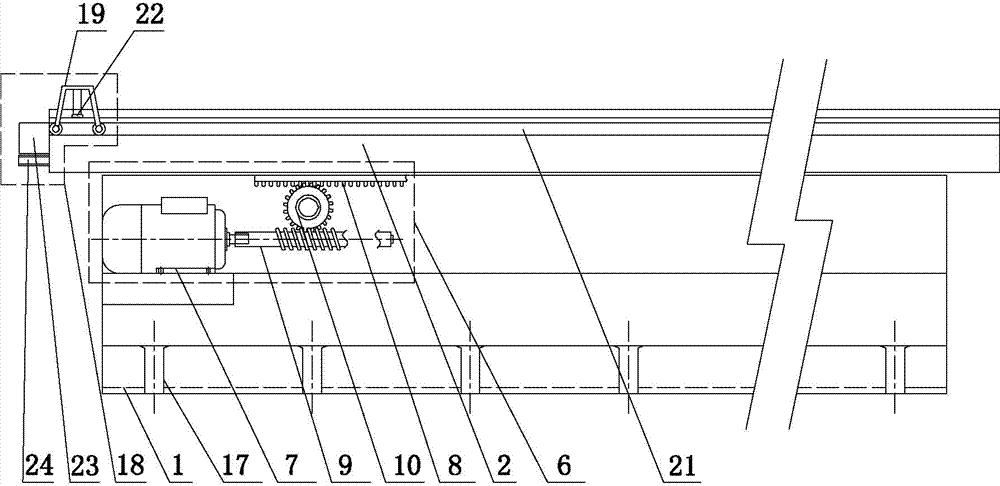

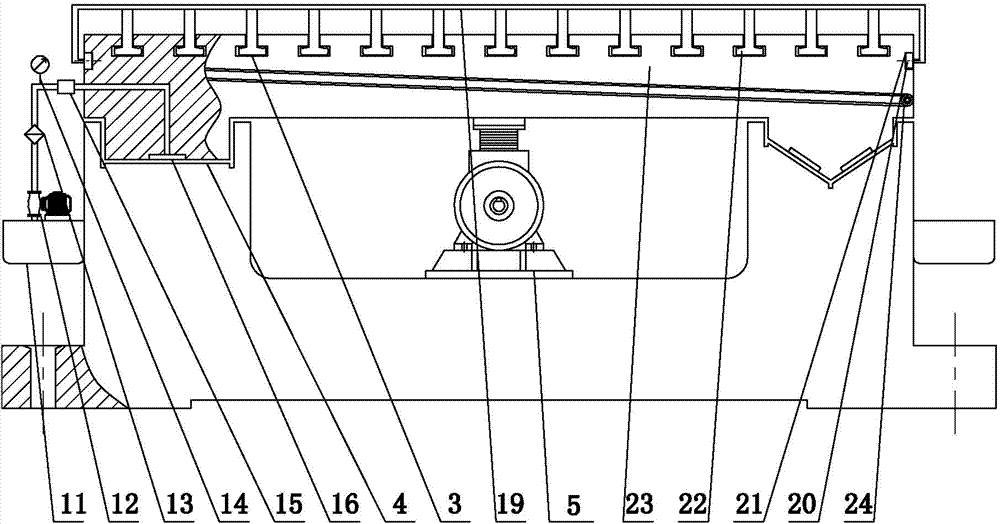

[0014] figure 1 Is a schematic diagram of the structure of the present invention, figure 2 It is the left side view of the present invention. Combine figure 1 , 2 It can be seen that the new machine tool bed casting assembly includes an integrated casting molded chassis base 1 and an integrated casting molding workbench 2, wherein the top of the workbench 2 is provided with multiple T-slots 3, and the bottom of the chassis base 1 is provided with multiple mounting holes 17. A guide rail 4 is provided on the top of the chassis base 1, and the guide rail can be a V-static pressure guide rail with good shock absorption performance. A bracket 5 is provided in the middle of the chassis base 1, and an X-axis drive device 6 connected to the workbench 2 is provided on the bracket 5. The X-axis drive device 6 includes a workbench drive motor 7 and a rack 8 provided at the bottom of the workbench 2. , The table driving motor 7 is connected to the end of the worm 9 on the shaft, the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com