Preparation method of dual bacteriostatic cinnamyl aldehyde microcapsule

A technology of cinnamaldehyde and microcapsules, which is applied in chemical preservation of meat/fish, food science, food preservation, etc. It can solve the problems of not protecting cinnamaldehyde well, easy to absorb water, swell and break, microcapsules are unstable, etc. Achieve good antibacterial effect, low antibacterial concentration, and reduce viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

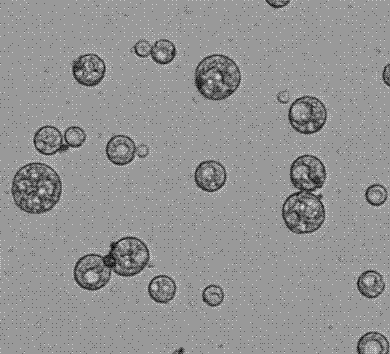

Image

Examples

Embodiment 1

[0021] 1. Dissolve 3g of chitosan in 300g of glacial acetic acid with a mass concentration of 1.0% to prepare a chitosan solution, add 3g of cellulase (enzyme activity 500u / mg), and carry out enzymatic hydrolysis reaction at 40°C for 4 hours to obtain Modified chitosan solution;

[0022] 2. Dissolve 15g of gum arabic in 2000ml of water to prepare a gum arabic solution, add 9g of cinnamaldehyde, and emulsify and disperse at a high speed for 4min at an emulsification speed of 10000 rpm to obtain an emulsion;

[0023] 3. Add the modified chitosan solution prepared in step 1 dropwise to the emulsion prepared in step 2 (the mass ratio of gum arabic to chitosan is 1:4), stir at 30°C for 30 minutes, and carry out Agglomeration reaction; after the agglomeration reaction, add 0.75g geniposide and solidify at room temperature for 1h;

[0024] 4. After solidification, carry out suction filtration to obtain wet double antibacterial cinnamon aldehyde microcapsules, adopt spray drying, the...

Embodiment 2

[0027] 1. Dissolve 0.75g of chitosan in 40g of glacial acetic acid with a mass concentration of 2.0% to prepare a chitosan solution, add 0.5g of cellulase (enzyme activity 2000u / mg), and carry out enzymatic hydrolysis reaction at 60°C for 1h , to obtain a modified chitosan solution;

[0028] 2. Dissolve 6g of gum arabic in 600ml of water to prepare a gum arabic solution, add 13.5g of cinnamaldehyde, and emulsify and disperse at a high speed for 3 minutes at an emulsification speed of 8000rpm to obtain an emulsion;

[0029] 3. Add the modified chitosan solution prepared in step 1 dropwise to the emulsion prepared in step 2 (the mass ratio of gum arabic to chitosan is 1:0.25), stir at 40°C for 20 minutes, and carry out Agglomeration reaction; after the agglomeration reaction, add 3.0 g of geniposide and solidify at room temperature for 4 hours;

[0030] 4. After curing, carry out suction filtration to obtain wet double antibacterial cinnamon aldehyde microcapsules, adopt spray ...

Embodiment 3

[0033] 1. Dissolve 3g of chitosan in 600g of glacial acetic acid with a mass concentration of 3.0% to prepare a chitosan solution, add 1g of cellulase (enzyme activity 1400u / mg), and carry out enzymatic hydrolysis reaction at 50°C for 3 hours to obtain Modified chitosan solution;

[0034] 2. Dissolve 18g gum arabic in 3600ml water to prepare a gum arabic solution, add 5.25g cinnamaldehyde, emulsify and disperse at a high speed for 5min at an emulsification speed of 12000rpm to obtain an emulsion;

[0035] 3. Add the modified chitosan solution prepared in step 1 dropwise to the emulsion prepared in step 2 (the mass ratio of gum arabic to chitosan is 1:1), stir at 50°C for 10 minutes, and carry out Agglomeration reaction; after the agglomeration reaction, add 3g of geniposide and solidify at room temperature for 2h;

[0036] 4. After solidification, carry out suction filtration to obtain wet double antibacterial cinnamon aldehyde microcapsules, adopt spray drying, the inlet air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com