Apparatus and method for measuring the weight of a continuous flow of reticulated fibrous material

A technology of fiber materials and mesh fibers, which is applied in the field of non-woven net devices, can solve the problems of not providing correction factors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

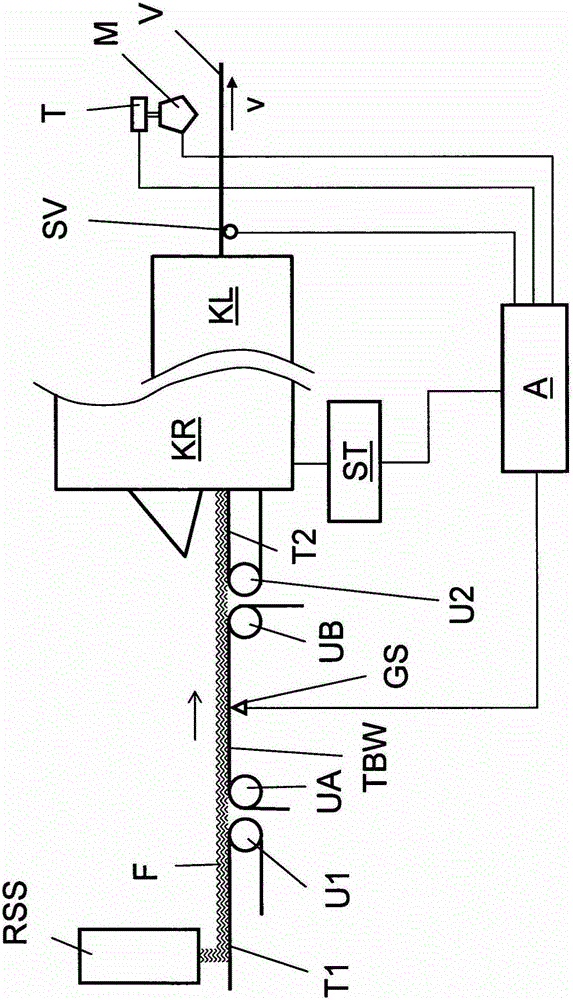

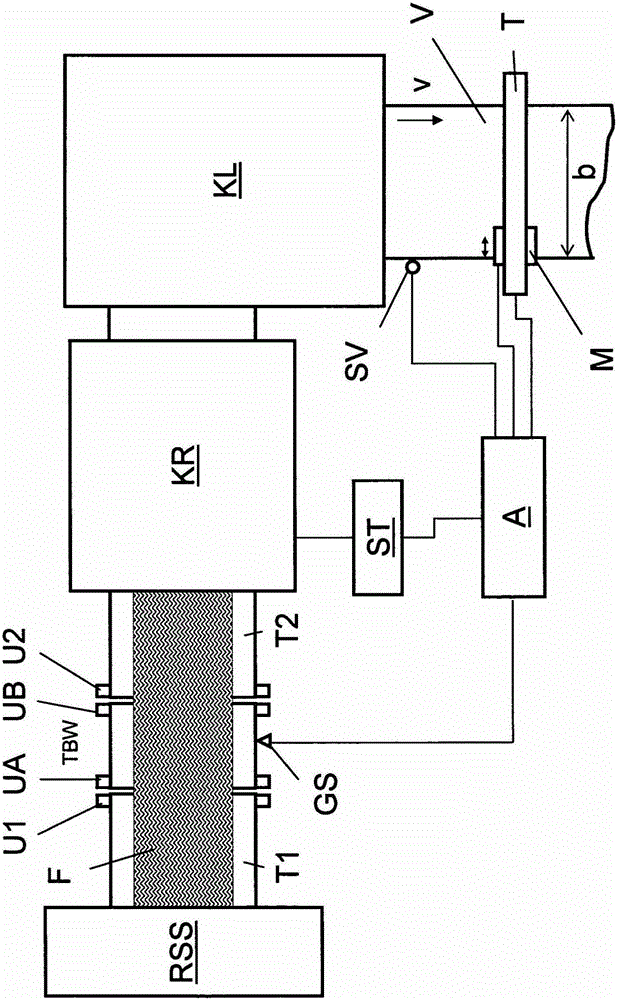

[0034] A vibration cute feed RSS forms a reticular fiber layer F on the first conveyor T1. The first conveyor belt T1 is guided around guide rollers U1 and in this region conveys the fiber layer F to a third endless conveyor belt TBW which circulates under tension in the direction of the arrows around guide rollers UA, UB. A further guide roller U2 extends parallel to the guide roller UB, which tensions the other conveyor belt T2. In the region of the guide rollers UB, U2, the fiber layer F is conveyed from the third endless conveyor belt TBW to the other conveyor belt T2. The conveyor belt T2 is coupled to a card KR (indicated only schematically in the drawing) and feeds this card.

[0035]Immediately downstream of the card KR is a crosslapper KL (also indicated only schematically) which superimposes the fluff formed by carding in order to obtain a nonwoven V. At the outlet of the crosslapper KL the nonwoven V has a speed v which is determined by a speed sensor SV. The spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com