Pixel structure and manufacturing method for the pixel structure

一种画素结构、制作方法的技术,应用在半导体/固态器件制造、仪器、半导体器件等方向,能够解决画素结构解析度难以提升、电容电极与漏极短路、关键尺寸不易控制等问题,达到提升解析度与开口率、避免短路、减少光罩数目的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

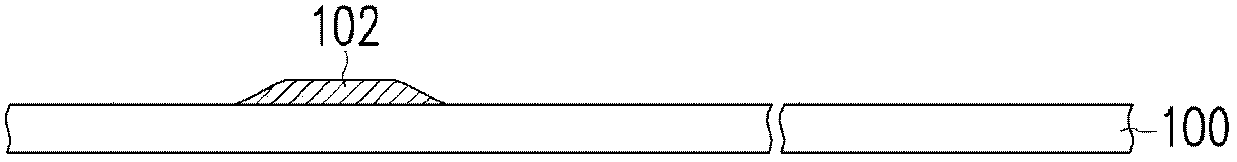

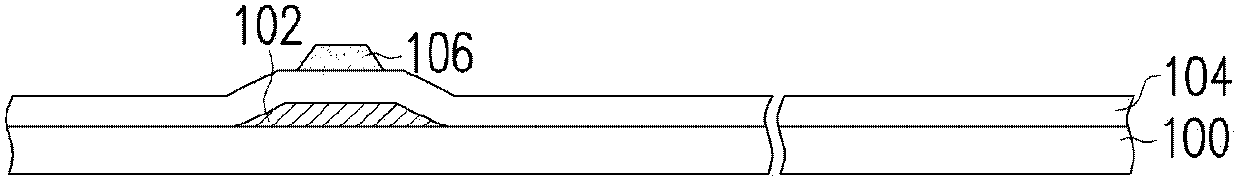

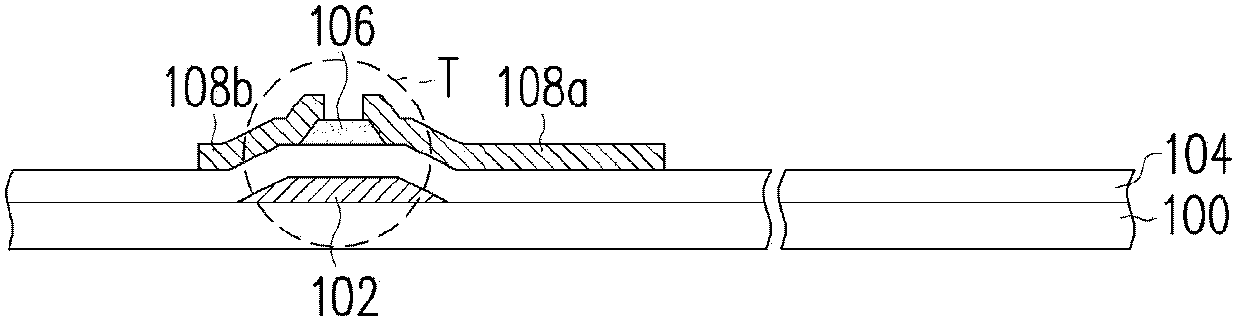

[0054] Figure 1A to Figure 1J It is a schematic flowchart of a method for manufacturing a pixel structure according to an embodiment of the present invention, Figure 2A for Figure 1J The schematic diagram of the top view, where Figure 1J The left part and right part of the ellipsis line are respectively along Figure 2A A schematic cross-sectional view of line A-A' and line B-B', and Figure 2B for Figure 2A An enlarged schematic view of the first to fourth openings of . First, please refer to Figure 1A to Figure 1D , forming a thin film transistor T on a substrate 100, and the thin film transistor T includes a first electrode 108a. In this embodiment, the substrate 100 includes, for example, an active area and a peripheral area (not shown), wherein Figure 1A to Figure 1J The described steps are performed on the substrate 100 in the active area. The thin film transistor T is, for example, a bottom gate (Bottom Gate) type thin film transistor, and its manufacturing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com