Method for catching and positioning electric arc of electrified railway contact net

A technology of electrified railway and positioning method, which is applied in the direction of measuring electricity, measuring electrical variables, optical testing flaws/defects, etc., and can solve problems such as inability to complete catenary continuous testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

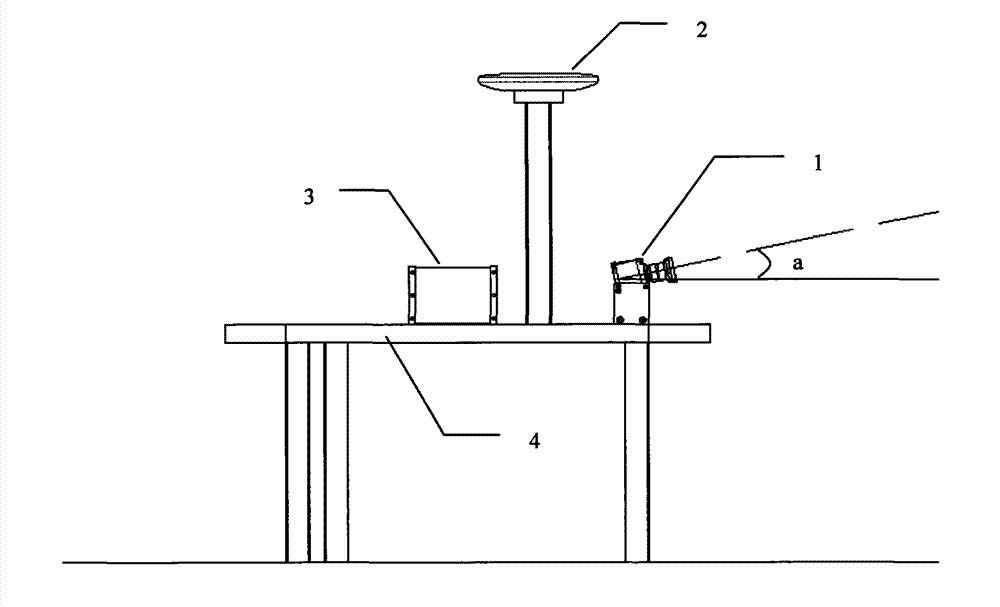

Embodiment 1

[0042] Embodiment 1: Assuming that the running speed of the electric locomotive is 350 km / h, i.e. 97.2 m / s, the frequency of the GPS receiver is 2 Hz, the frequency of the IMU is 256 Hz, and the positioning accuracy of the differential GPS / IMU is centimeter level, in this embodiment The high-speed digital imaging device 1 selects a high-speed digital camera, and the shooting speed is 2000 frames per second, so the positioning accuracy of the arc is about 5 cm. If you need to improve the positioning accuracy, you can choose a higher shooting speed. The capture and positioning of the arc does not require high image resolution, and the optimization of storage and arc recognizability must be considered comprehensively here. The lens of the high-speed digital imaging device 1 should be a fixed-focus lens, and the focal point is the contact point between the pantograph and the railway catenary.

Embodiment 2

[0043] Embodiment 2: in the present embodiment, high-speed digital imaging equipment 1 selects high-speed digital thermal infrared camera for use, and the shooting speed is 160 frames per second. Assuming that the running speed of the electric locomotive is 300 kilometers per hour, that is, 83.3 meters per second, the GPS receiver The frequency is 2Hz, the frequency of the IMU is 256Hz, and the positioning accuracy of the differential GPS / IMU is centimeter level. The acquired data will be continuous temperature data every 0.5 meters. During data processing, the temperature range can be set to classify the data , this method can not only locate the start and end positions of the arc, but also monitor the abnormal temperature of the entire line of the catenary. Similarly, the way to improve positioning accuracy is to choose a thermal infrared camera with faster shooting speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com