Miniature onboard reverse plug flow cloud droplet sampling device and working method thereof

A technology of sampling device and minicomputer, which is applied in the direction of sampling device, etc., can solve the problems of high purchase cost, large size of aviation atmospheric observation sampler, hindering research development, etc., and achieve the effect of convenient processing, convenient application and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

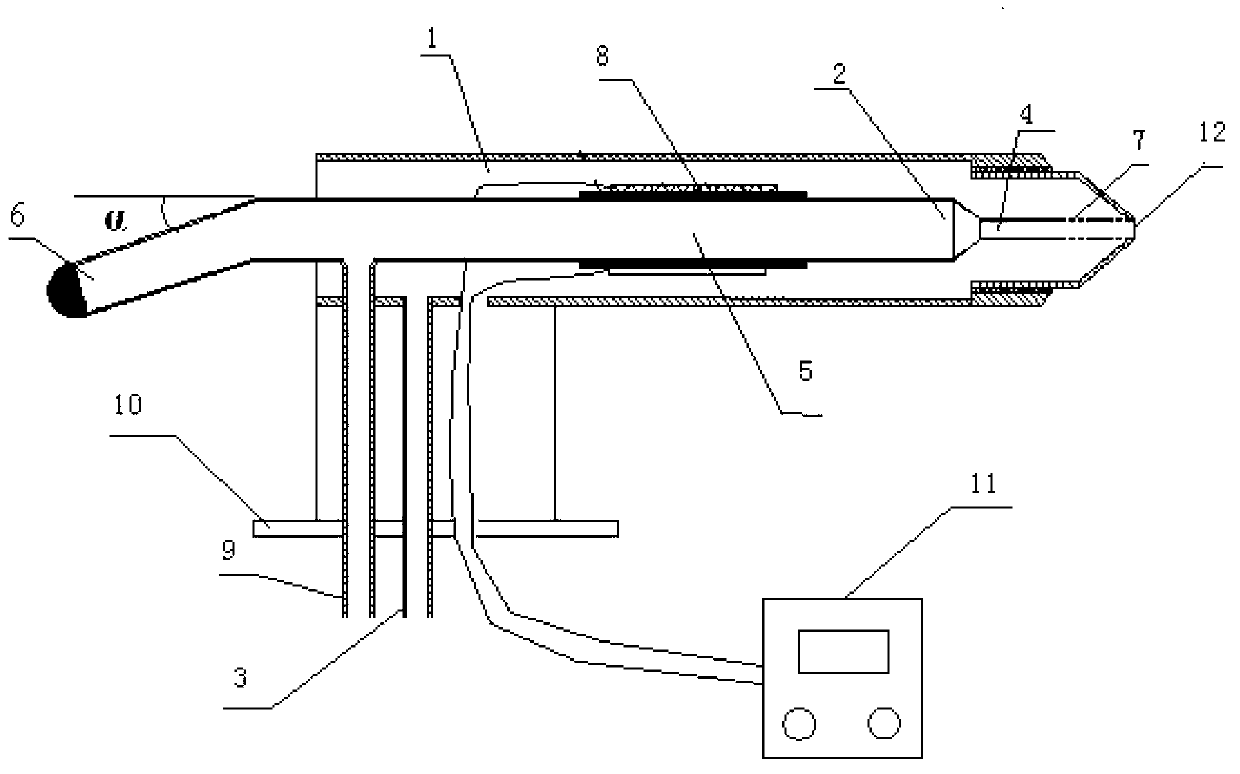

[0026] A small-sized airborne reverse push flow cloud drop sampling device, comprising an air intake chamber 1 and a collection chamber 2, the collection chamber 2 is arranged inside the air intake chamber 1; the front end of the air intake chamber 1 and the sampling chamber of the collection chamber The outer edge of the end is connected, the front end of the air inlet chamber 1 is tapered, and the tail of the air inlet chamber 1 is provided with an air inlet pipe 3; the collection chamber 2 includes a tubular sampling end 4 connected in sequence, a preheating chamber 5 and a tubular capture end 6, the tube wall of the tubular sampling end 4 is provided with a microhole 7, and a heating device 8 is arranged around the outer wall of the preheating cavity 5, and the heating device is a heating rod Thermocouple; an exhaust pipe 9 is arranged at the tail of the preheating cavity 5, and the preheating cavity 5 is a copper tube.

[0027] Described small-sized airborne reverse push ...

Embodiment 2

[0030] A method of collecting cloud droplets utilizing the small-sized airborne reverse push flow cloud droplet sampling device described in embodiment 1, comprising steps as follows:

[0031] (1) The sample gas enters the intake chamber 1 along the intake pipe 3, and heats the preheating chamber 5 to 48-52°C;

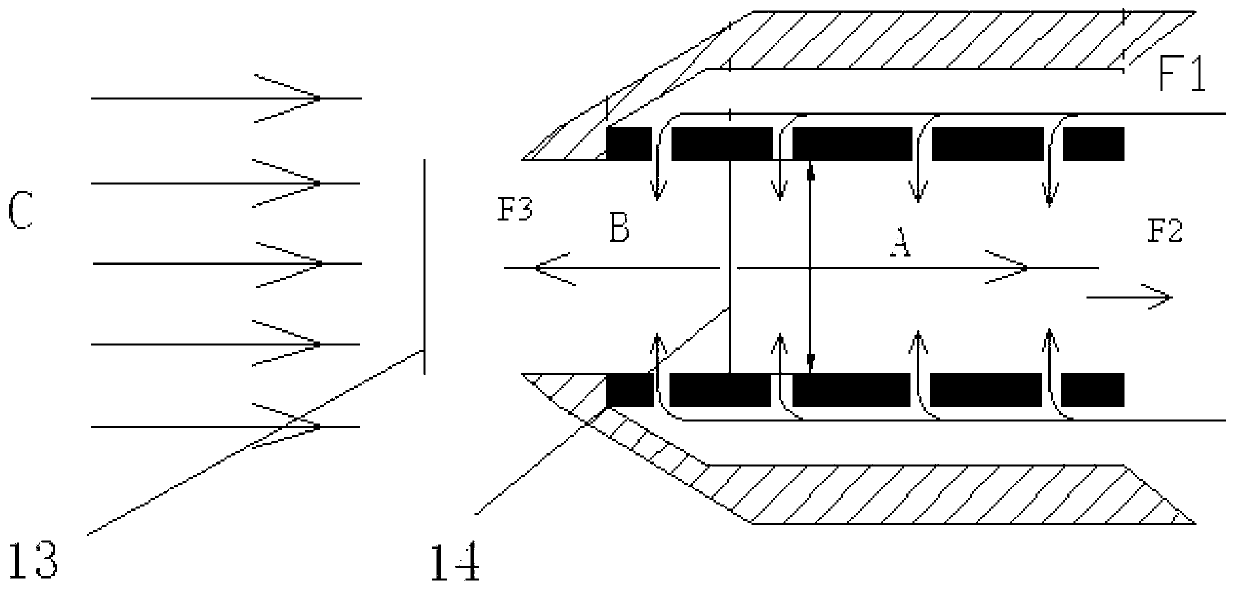

[0032] (2) The sampling gas in the intake chamber 1 enters the collection chamber 2 along the micropore 7 on the tubular sampling end 4, the flow rate F1 of the sampling gas in the intake pipe 3 is greater than the flow rate F2 of the exhaust pipe, and the When the sampling gas passes through the tubular sampling end 4 with micropores 7, it is divided into two channels of sampling gas: the flow rate F2 and direction of the sampling gas A of one channel are the same as that of the sampling gas in the extraction pipe, and the sampling gas B of the other channel is the same as that of the sampling gas in the extraction tube. The direction is opposite, the flow is F3; the ...

Embodiment 3

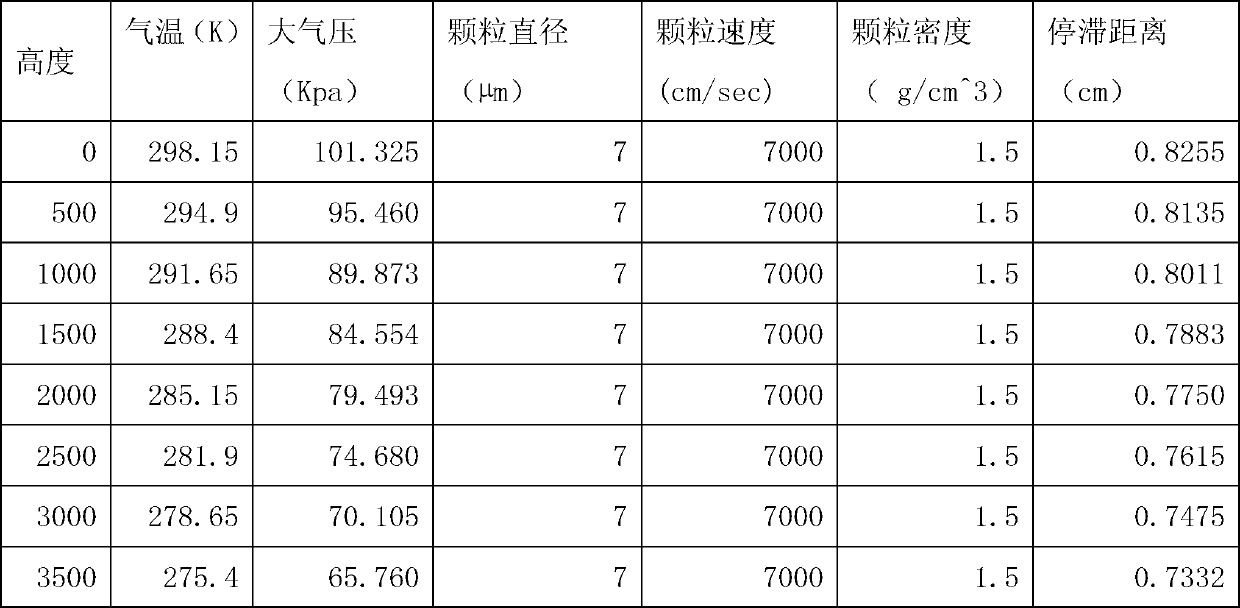

[0040] Cloud drop sampling device as described in embodiment 1, its difference is,

[0041] The length of the tubular sampling end 4: 8mm, the diameter of the tubular sampling end: 1.5mm; there are many circles of microholes around the tubular sampling end, the number of microholes in each circle is 6, and the interval between adjacent circles is 1.5 mm. mm; the diameter of the micropore: 10 μm; the diameter of the preheating cavity: 4 mm; the diameter range of the air inlet cavity: 18 mm. The tubular capturing end is at an angle of 25° counterclockwise to the horizontal.

[0042] The particle size range of the aerosol particles or cloud droplets collected by the cloud droplet sampling device described in this embodiment is between 5-10 μm, which meets the experimental requirements for selectively collecting large aerosol particles or cloud droplets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com