O-shaped sealing ring sealing pressure test method and its sealing device

A sealing ring and pressure test technology, which can be used in the direction of measuring the acceleration and deceleration rate of fluid and using liquid/vacuum for liquid tightness measurement. The effect of small pressing amount and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

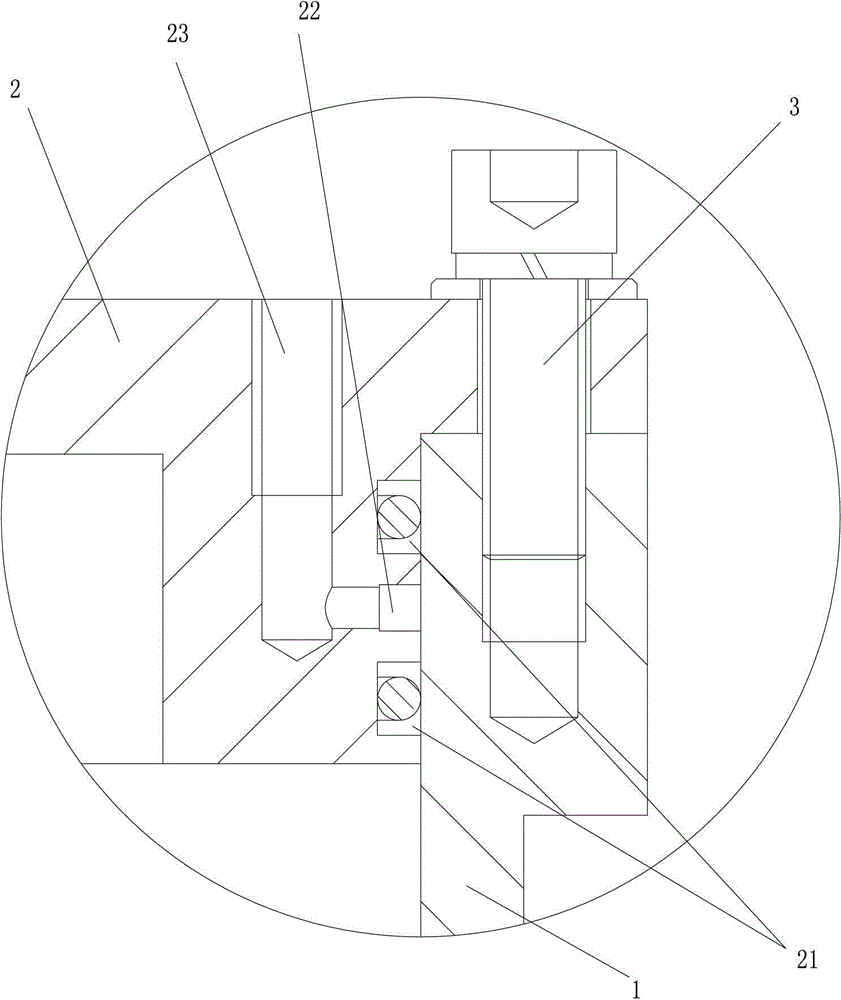

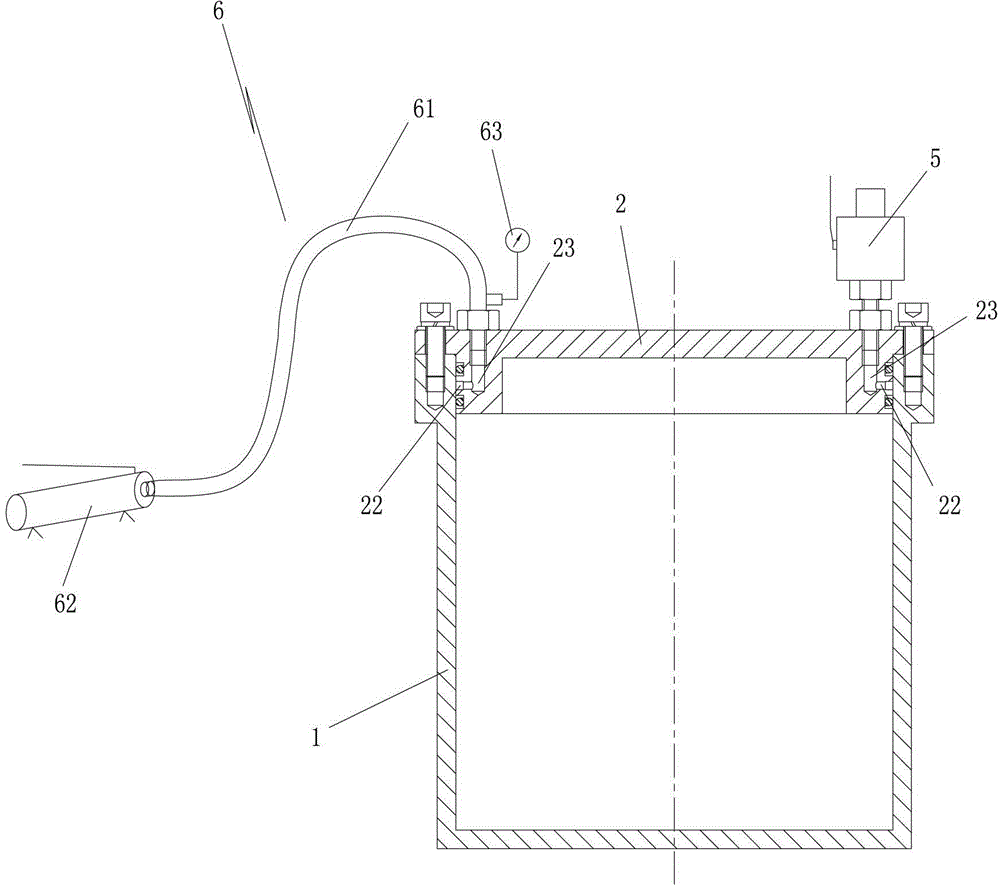

[0021] The present invention proposes a sealing and pressure testing method for an O-shaped sealing ring. Two O-ring grooves are arranged on the sealing surface of one side of the sealing joint surface, and a guide for the sealing joint surface is arranged between the two O-ring grooves in parallel. Injection pressure ring groove through; each O-ring groove is provided with an O-ring; a preset pressure (can be oil pressure, water pressure or air pressure, etc.) For a certain period of time, the sealing effect of the O-ring seals on both sides of the injection pressure ring groove is detected.

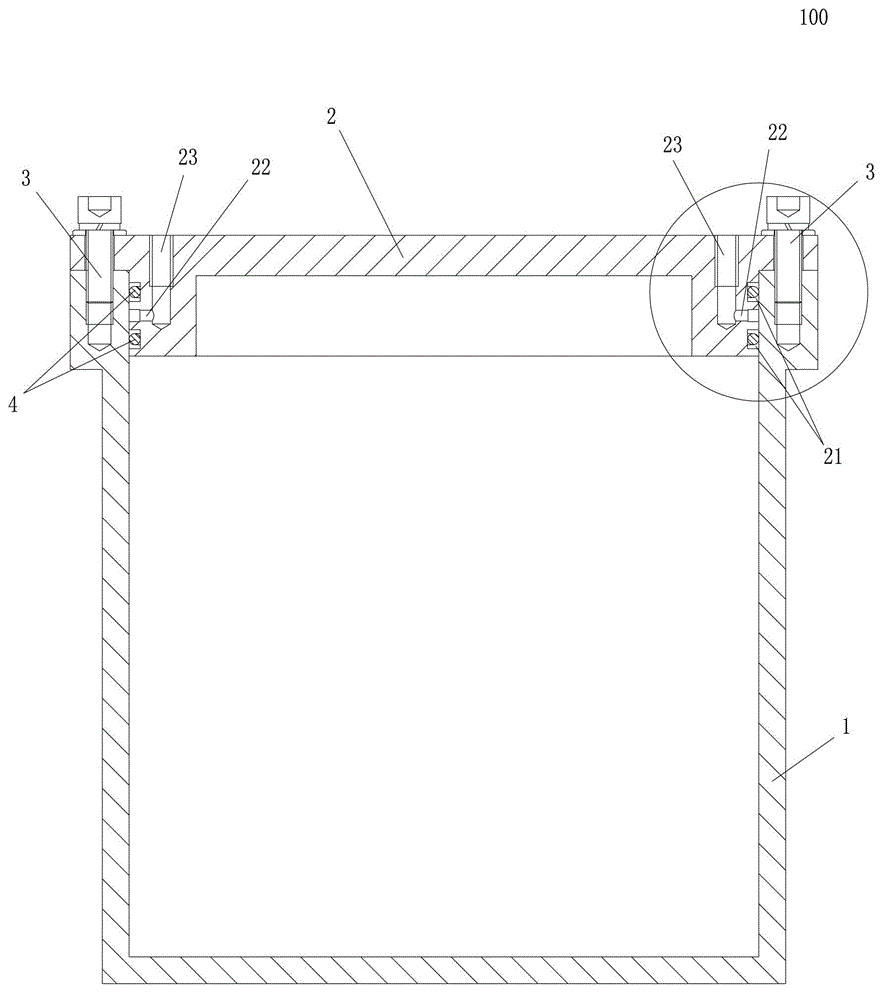

[0022] Such as Figure 1A , Figure 1B and figure 2 As shown, according to the above-mentioned pressure testing method, the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com