Intelligent digital display angle sensor

An angle sensor and digital display technology, applied in the direction of instruments, measuring devices, etc., can solve the problems of unfavorable intelligent setting and control, and cannot effectively change the on-site calibration, so as to eliminate the risk of damage, simplify the difficulty of installation and debugging, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

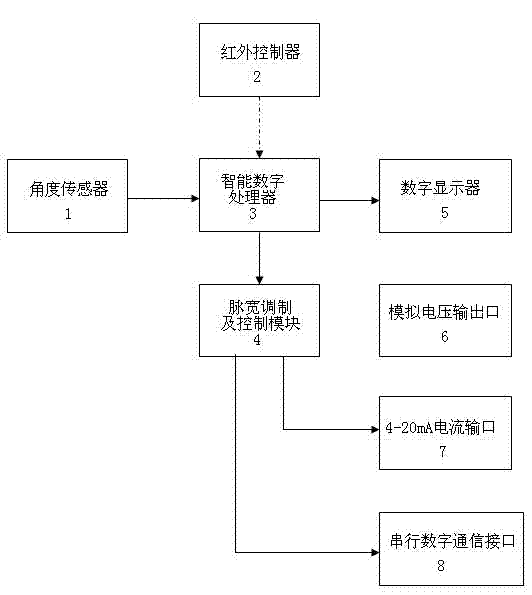

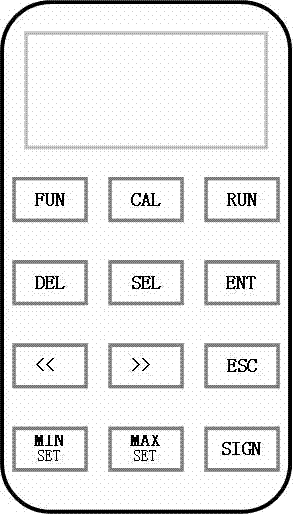

[0025] see figure 1 ,, This intelligent digital display angle sensor includes a high-sensitivity angle sensor chip, a built-in industrial microprocessor, pulse width modulation and control module, digital display and infrared remote control. It is characterized in that the microprocessor is connected with an angle sensor, a pulse width modulation and control module and a digital display, and is connected with an infrared remote controller through wireless communication; the pulse width modulation and control module is connected with an analog voltage output port and a 4-20mA current output port and a serial digital communication interface, the angle sensor outputs the measured angle signal to the microprocessor in the form of analog voltage, and the microprocessor quantifies and digitizes the analog quantity at 2048 levels through the built-in analog-to-digital converter, so The collected voltage value is converted into a corresponding digital value through smooth operati...

Embodiment 2

[0027] The system structure of this intelligent digital display angle sensor is as follows: figure 1 As shown, it mainly includes a high-sensitivity angle sensor chip, a built-in industrial microprocessor, a pulse width modulation and control module, a signal conversion module and an infrared remote control handheld terminal. The angle sensor outputs the measured angle signal to the microprocessor in the form of analog voltage, and the microprocessor quantifies and stores the analog quantity in 2048 levels through the built-in analog-to-digital converter (ADC), and the collected voltage value is smoothed Digital processing such as calculation, linear correction, temperature compensation, and precision adjustment converts angle values into corresponding digital values. The obtained angle digital value is directly displayed through the segment selection signal of the digital tube for on-site observation; at the same time, the signal is output as a pulse width modulation (PWM)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com