Organic solid fuel drying, pyrolyzing and incinerating integrated method and organic solid fuel drying, pyrolyzing and incinerating integrated device

A drying device and organic solid technology, applied in the direction of combustion methods, incinerators, combustion types, etc., can solve the problems of incomplete differentiation and mutual mixing, and achieve the effects of simple structure, energy saving, and high-efficiency utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

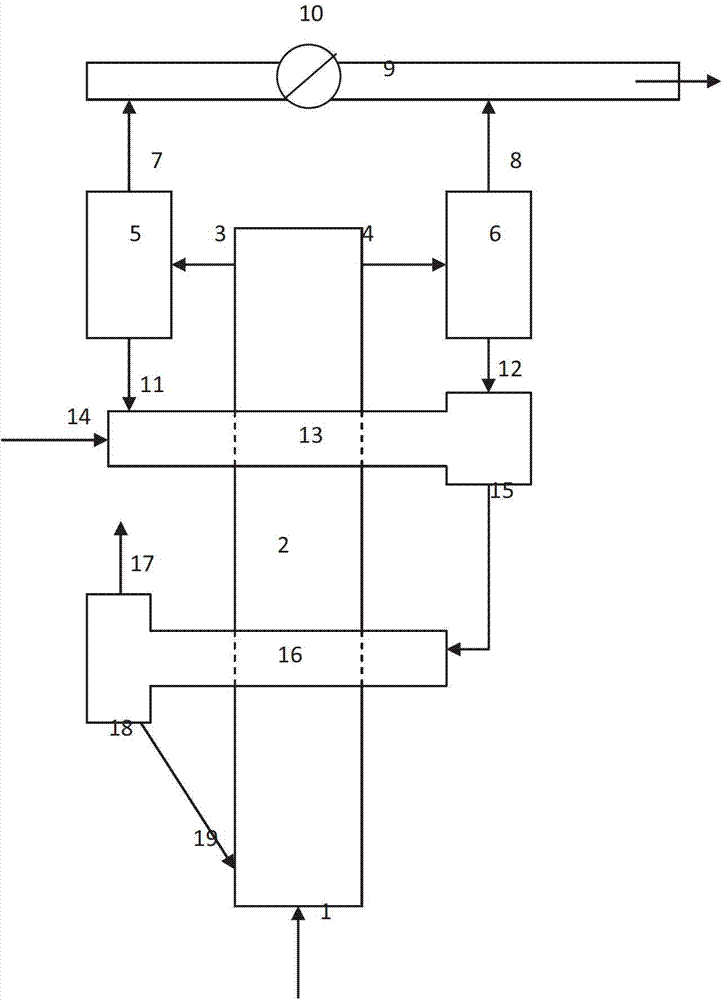

[0011] An organic solid fuel drying, pyrolysis and incineration integrated device of the present invention will be described in detail below in conjunction with the technical scheme and accompanying drawings.

[0012] The organic solid fuel drying, pyrolysis and incineration integrated device of the present invention is composed of an incineration device 2 , a left dust collector 5 and a right dust collector 6 , a regulating valve 10 , a drying device 13 and a pyrolysis device 16 . The upper part of the incineration device 2 is provided with a left outlet 3 and a right outlet 4 which are respectively connected with two left dust collectors 5 and right dust collectors 6 . The gas left outlet 7 and the right outlet 8 of the dust collector are respectively connected with the air induction pipe 9, and a regulating valve 10 is set in the middle part of the two connections, and the regulating valve adjusts the air flow rate according to the temperature of the drying device 13 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com