Heavy oil steam huff and puff injection-production integrated device

A technology of steam and heavy oil, which is applied in isolation devices, production fluids, earth drilling, etc. It can solve the problems of wasting heat energy, manpower and material resources, many operations, and low thermal recovery efficiency, so as to reduce device maintenance costs and improve production Good effect of aging and heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

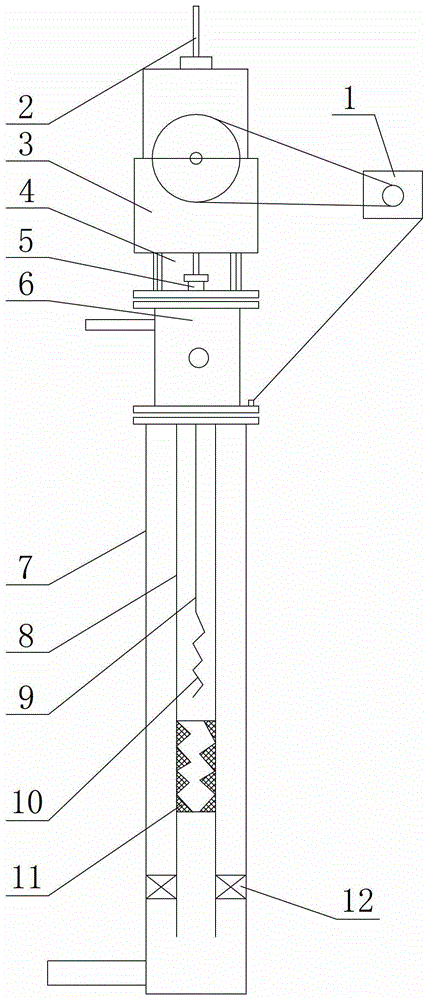

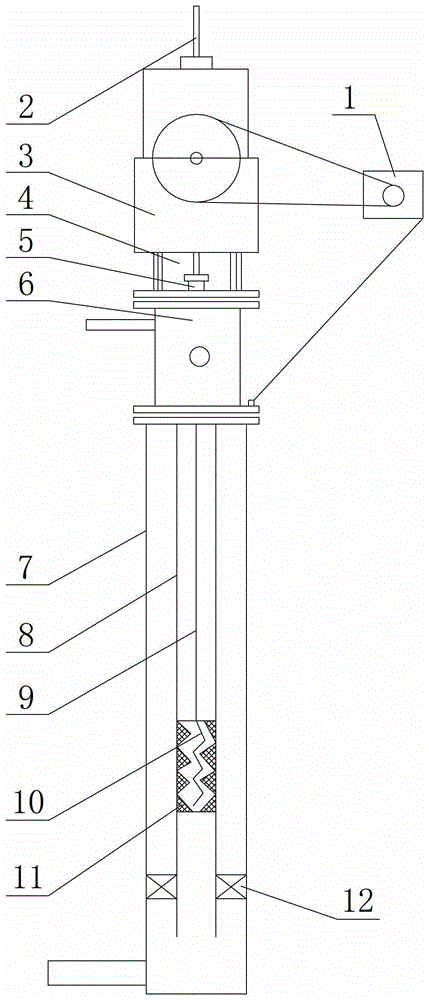

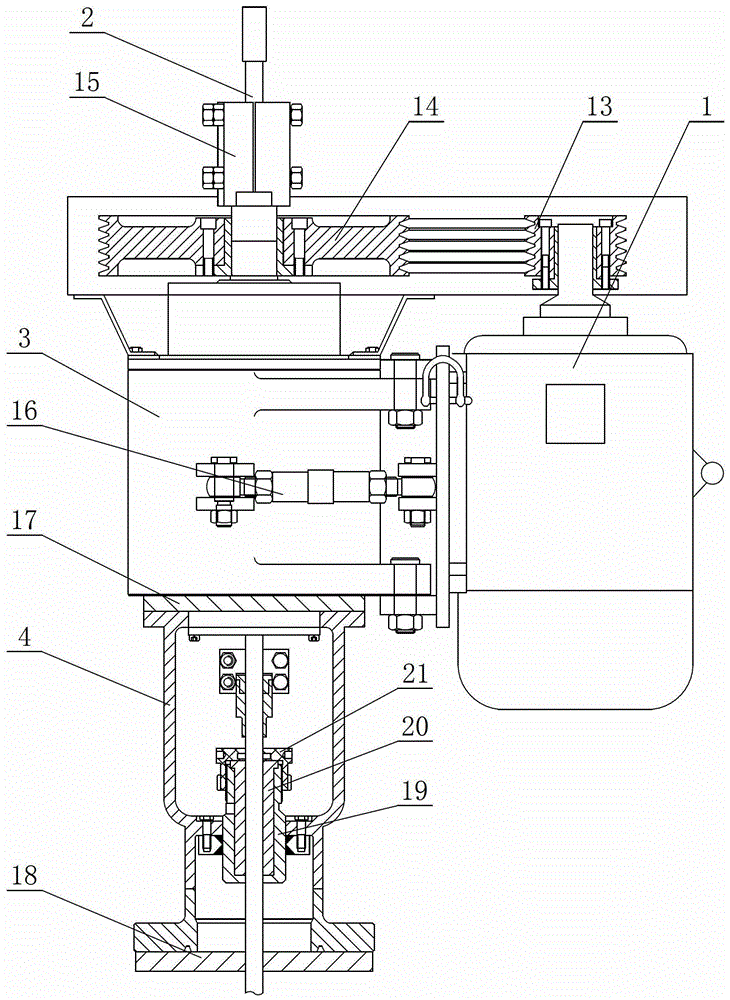

[0020] Please refer to Figure 1 to Figure 3 As shown, in this embodiment, a heavy oil steam huff-puff injection-production integrated device includes an uphole part and a downhole part. 8. Sucker rod 9, bimetallic screw pump, and cam anchor 12. The driving device includes a base 4, a box body 3, a motor 1 and a motor base. The lower end of the steam injection and oil production integrated wellhead 6 passes through the flange and the casing The oil well casing 7 is set outside the oil pipe 8, and the bottom of the oil pipe 8 is connected with the stator 11 of the bimetallic screw pump. The stator 11 is made of 38CrMoAl round steel, and its Vickers hardness is 800~ 1000HV, the lower end of the stator 11 is provided with a cam anchor 12 for fixing the oil pipe 8, the cam anchor 12 prevents the oil pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com