Integral ballast bed lateral restraining device

A restraining device and an integrated technology, applied in the field of rail transit, can solve the problems of short ballast bed maintenance period, insufficient vertical and horizontal resistance, and insufficient lateral restraint of ballast bed structure, so as to improve the ballast bed bearing capacity and vertical and horizontal resistance, The effect of strong integrity and flexible arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in conjunction with the accompanying drawings.

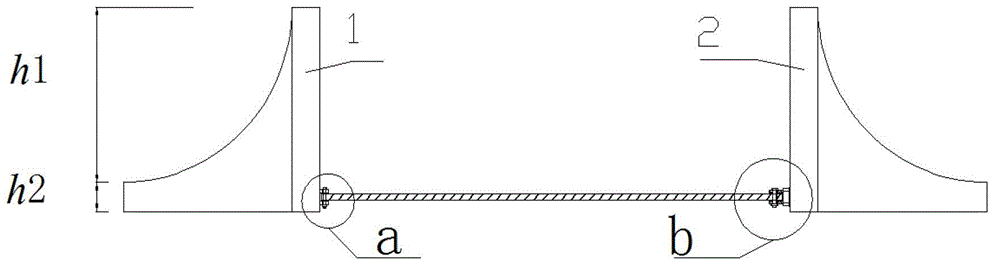

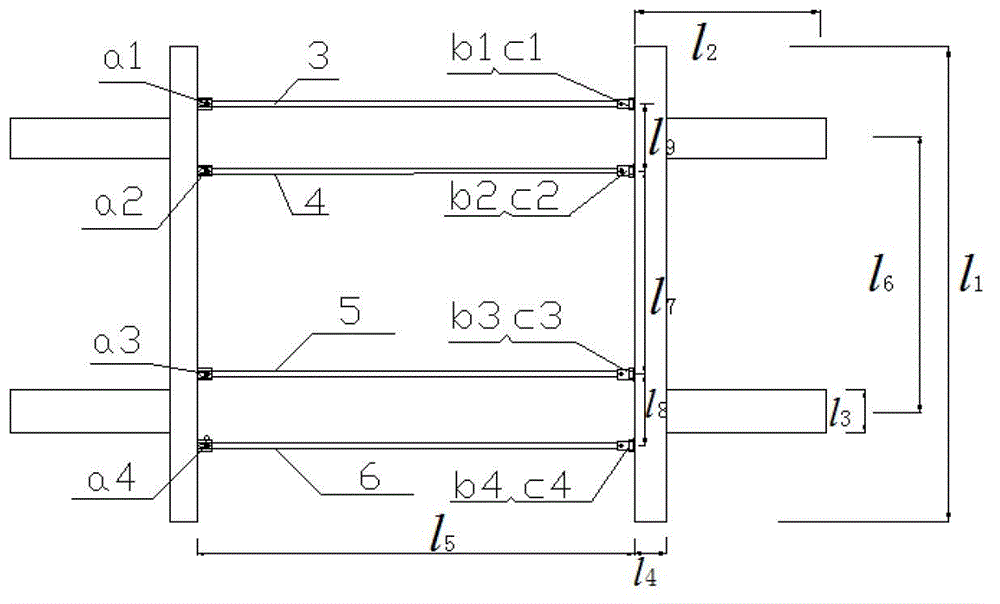

[0038] An integral ballast bed lateral restraint device, such as figure 1 , 2 , the restraint device includes:

[0039] Left integral reinforced concrete baffle 1, right integral reinforced concrete baffle 2, first to fourth epoxy resin wire ropes 3, 4, 5, 6, first to fourth left connectors a1, a2, a3, a4, the first One to the fourth right connecting piece b1, b2, b3, b4, the first to the fourth internally threaded sleeve c1, c2, c3, c4.

[0040] A circular hole with a radius of 2 to 3 cm is opened at the middle distance top surface 5 cm to 8 cm of the left integral reinforced concrete baffle 1, and the circular hole is used for installation and disassembly of the device; the back of the ballast retaining surface The sides are supported by two circular arcs. Its specific dimensions, such as figure 1 , 2 . The length l of the left integral reinforced concrete baffle 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com