Method for preparing suede waterborne polyurethane superfine fiber synthetic leather

A water-based polyurethane and microfiber technology, applied in dyeing, textile and papermaking, etc., can solve the problems of heavy metals easily exceeding the standard in neutral dye dyeing, poor thermal migration resistance of disperse dyes, DMF pollution, etc., and achieve good health. , The effect of solving product safety problems and safe production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

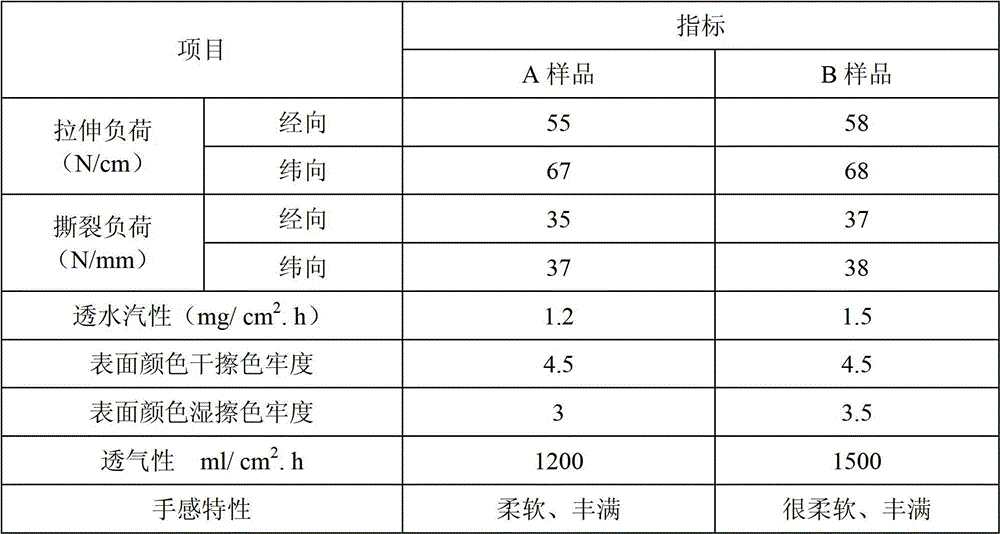

Examples

Embodiment 1

[0044] 1) Impregnation compounding of non-woven fabric and cationic water-based polyurethane

[0045] 1.1) Preparation of immersion solution

[0046] Mix 20 parts of cationic water-based polyurethane with a solid content of 30% and 35 parts of water by weight to obtain an impregnating liquid;

[0047] 1.2) Preparation of coagulation liquid

[0048] Mix 10 parts by weight of inorganic salt sodium sulfate, 5 parts of inorganic alkali sodium carbonate and 60 parts of water under stirring to dissolve inorganic salt and inorganic alkali to obtain coagulation liquid;

[0049] 1.3) Impregnation compounding process

[0050] First, pass the nylon 6 / polyethylene bi-component fiber non-woven fabric through an impregnation tank equipped with an impregnation liquid with a temperature of 35 ° C, so that the impregnation liquid is saturated with the nylon 6 / polyethylene bi-component fiber non-woven fabric;

[0051] Secondly, the impregnated nylon 6 / polyethylene bicomponent fiber non-woven...

Embodiment 2

[0060] 1) Impregnation compounding of non-woven fabric and cationic water-based polyurethane

[0061] 1.1) Preparation of immersion solution

[0062] Mix 65 parts of cationic water-based polyurethane with a solid content of 30% and 70 parts of water by weight to obtain an impregnating liquid;

[0063] 1.2) Preparation of coagulation liquid

[0064] By weight, 20 parts of inorganic salt sodium chloride, 8 parts of inorganic alkali sodium bicarbonate and 80 parts of water are mixed under stirring to dissolve inorganic salt and inorganic alkali to obtain coagulation liquid;

[0065] 1.3) Impregnation compounding process

[0066] First, pass the nylon 6 / polyethylene bicomponent fiber non-woven fabric through an impregnation tank equipped with an impregnation liquid with a temperature of 30 ° C, so that the impregnation liquid is saturated with the nylon 6 / polyethylene bicomponent fiber nonwoven fabric;

[0067] Secondly, the impregnated nylon 6 / polyethylene bicomponent fiber no...

Embodiment 3

[0076] 1) Impregnation compounding of non-woven fabric and cationic water-based polyurethane

[0077] 1.1) Preparation of immersion solution

[0078] Mix 60 parts of cationic water-based polyurethane with a solid content of 30% and 80 parts of water by weight to obtain an impregnating liquid;

[0079] 1.2) Preparation of coagulation liquid

[0080] Mix by weight 15 parts of inorganic salt ammonium sulfate, 9 parts of inorganic alkali sodium hydroxide and 85 parts of water under stirring to dissolve inorganic salt and inorganic alkali to obtain coagulation liquid;

[0081] 1.3) Impregnation compounding process

[0082] First, pass the nylon 6 / polyethylene bi-component fiber non-woven fabric through an impregnation tank equipped with an impregnation liquid with a temperature of 40 ° C, so that the impregnating liquid is saturated with the nylon 6 / polyethylene bi-component fiber non-woven fabric;

[0083] Secondly, the impregnated nylon 6 / polyethylene bicomponent fiber non-wov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com