Blast furnace operation closed-loop control system

A closed-loop control, blast furnace operation technology, applied in blast furnace, blast furnace details, comprehensive factory control, etc., can solve the problems of unstable molten iron quality, different analysis and processing, and increased fuel consumption, so as to eliminate individual operation differences and reduce production costs. , the effect of prolonging the life of the blast furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

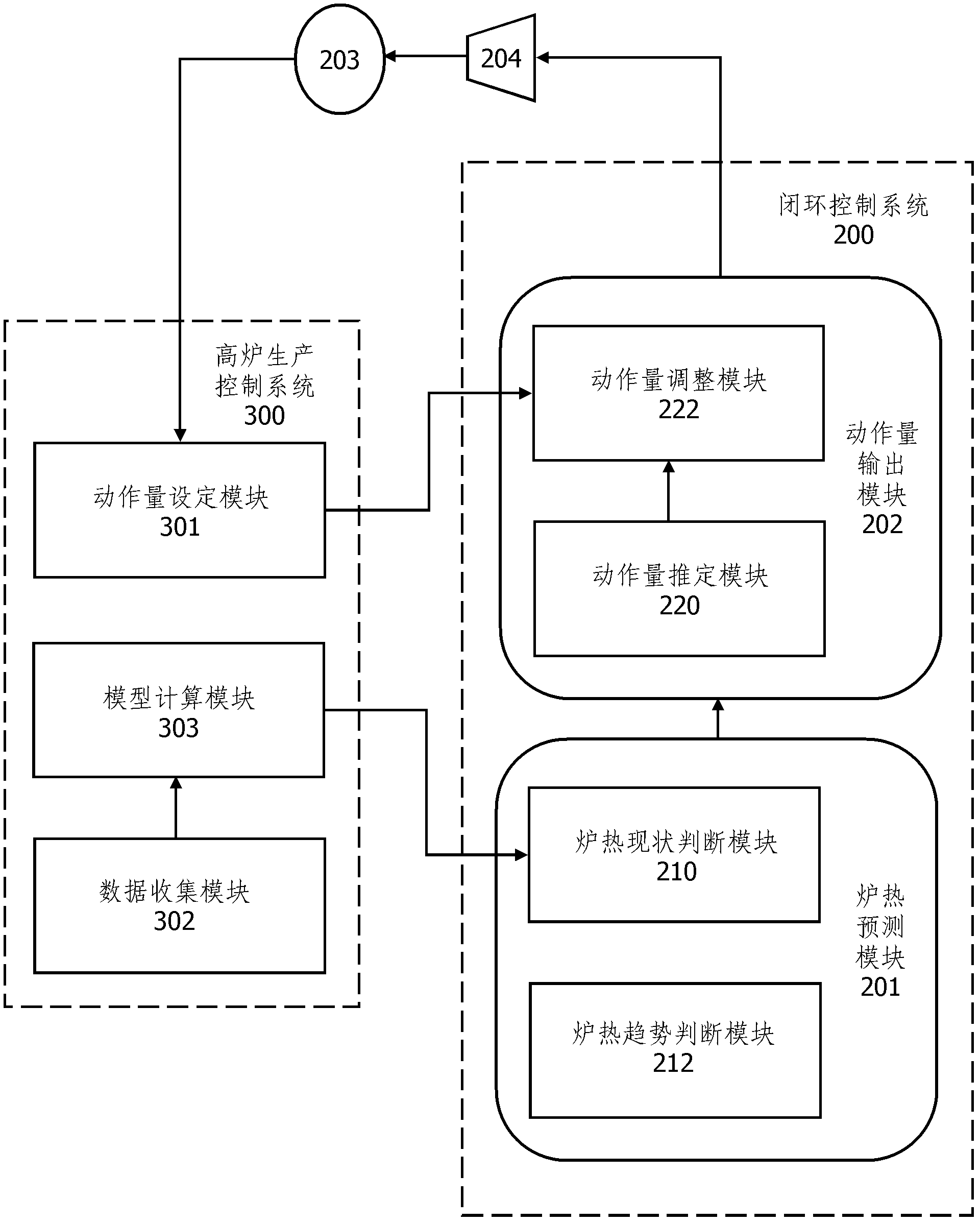

[0020] refer to figure 2 As shown, a structural diagram of a closed-loop control system for blast furnace operation according to an embodiment of the present invention is disclosed. The closed-loop control system 200 for blast furnace operation is connected to a blast furnace production control system 300. The closed-loop control system 200 for blast furnace operation includes: Heat prediction module 201 and action amount output module 202.

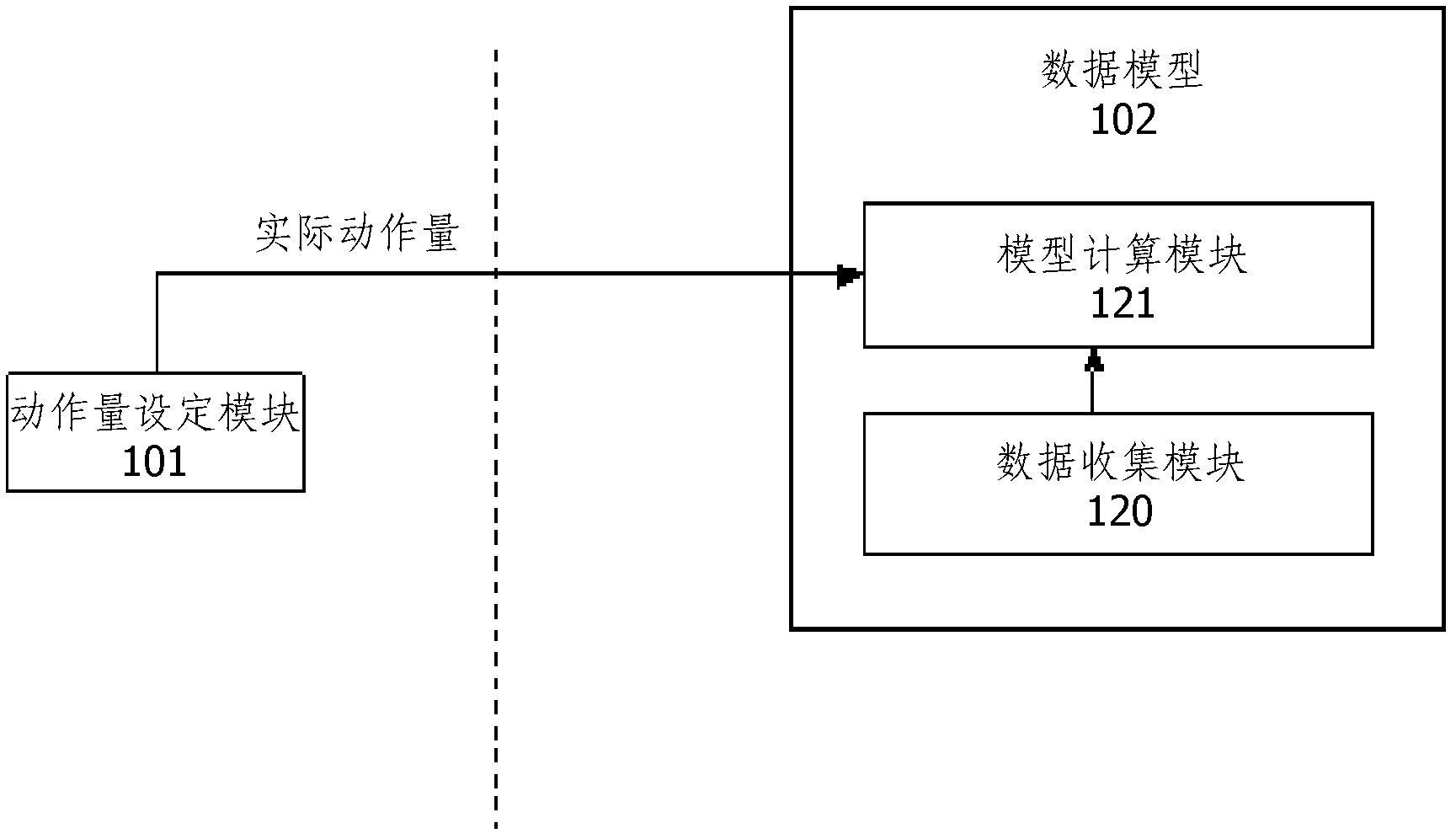

[0021] refer to figure 2 In the shown embodiment, the blast furnace production control system 300 suitable for use with the closed-loop control system of the present invention includes: an action amount setting module 301 , a data collection module 302 and a model calculation module 303 . The motion amount setting module 300 executes the motion amount adjustment according to the motion amount adjustment parameter generated by the motion amount output module 202 , and collects and feeds back the actual motion amount performed to the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com