Yellow wine brewed by taking malt syrup as raw material and brewing method thereof

A technology for maltose syrup and rice wine, applied in the field of rice wine, can solve the problems of short shelf life of finished rice wine, heavy bitterness and astringency of rice wine, slow filtration speed, etc., achieve elegant aroma characteristics, improve bitterness and astringency, and achieve the effect of zero emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Mix the acid rice milk water produced in the traditional rice wine brewing process with clear water, and the total acid of the mixed water is 2.93g / L.

[0039] 2) Take 24kg of mixed water and heat it to 100°C, keep it warm for about 30 minutes, add 16kg of maltose syrup, and fully dissolve it.

[0040] 3) Cool the sugar solution described in 2) to 26°C, add 2.4kg of distiller's mother, 1.6kg of wheat koji and 1.6g of protease. Drop cans. The drop tank temperature is controlled at 27.5°C.

[0041] 4) Stir once a day during the fermentation process, the fermentation temperature is controlled at 25.0-29.5°C, and the fermentation period is 20 days.

[0042] 5) Squeeze, clarify, and decoct wine.

[0043] The brewed product is light yellow, clear and translucent, with a mellow and elegant aroma, a refreshing and mellow taste, and has the typical style of rice wine products.

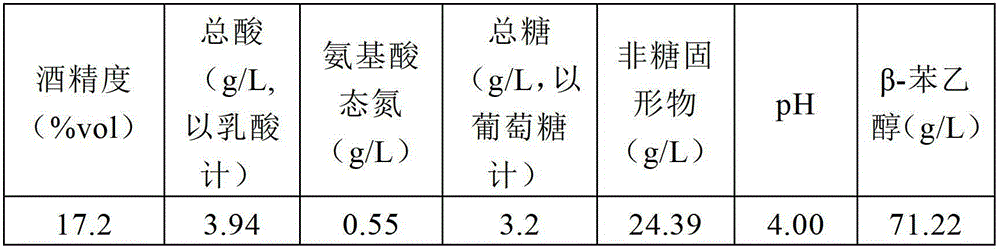

[0044] The alcohol yield rate is 221.5%. The key physical and chemical indicators of the test...

Embodiment 2

[0047] 1) Mix the acid rice milk water produced in the traditional rice wine brewing process with clear water, and the total acid of the mixed water is 3.95g / L.

[0048]2) Take 3000kg of mixed water and heat it to 100°C, keep it warm for about 30 minutes, add 2040kg of maltose syrup, and fully dissolve it.

[0049] 3) Cool the sugar solution in 2) to 26°C, add 200kg of distiller's mother, 200kg of wheat koji and 200g of protease, and drop it into the tank. The drop tank temperature was controlled at 25°C.

[0050] 4) Stir once a day during the fermentation process, the fermentation temperature is controlled at 25.8-28.5°C, and the fermentation period is 12 days.

[0051] 5) Squeeze, clarify, and decoct wine.

[0052] The brewed product is light yellow, clear and translucent, with a mellow and elegant aroma, a refreshing and mellow taste, and has the typical style of rice wine products.

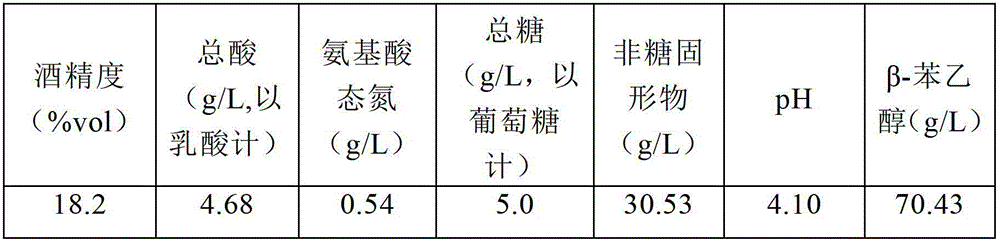

[0053] The alcohol yield rate was 259.2%. The key physical and chemical indicators of ...

Embodiment 3

[0056] 1) Take 600kg of water and heat it to 100°C, keep it warm for about 30 minutes, add 408kg of maltose syrup, and fully dissolve it.

[0057] 2) Cool the sugar solution described in 1) to 26°C, add 40kg of distiller's mother, 40kg of wheat koji and 40g of protease, and drop it into the tank. The drop tank temperature was controlled at 25°C.

[0058] 3) Stir once a day during the fermentation process, the fermentation temperature is controlled at 25.8-29.6°C, and the fermentation period is 7 days.

[0059] 4) Squeeze, clarify, and decoct the wine.

[0060] The brewed product is light yellow, clear and translucent, with a mellow and elegant aroma, a refreshing and mellow taste, and has the typical style of rice wine products.

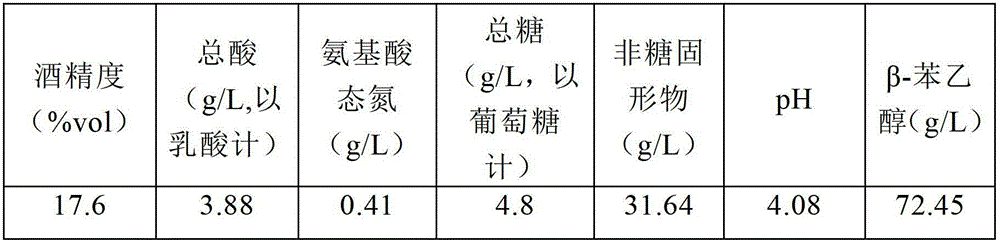

[0061] The yield rate was 246.7%. The key physical and chemical indicators of the test are in line with the national standard of GB / T 13662-2008 "rice wine".

[0062]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com