Hydrogenation method for preparation of biodiesel

A biodiesel and hydrogen preparation technology, which is applied in the preparation of biological raw materials, biofuels, liquid hydrocarbon mixtures, etc., can solve the problems of high freezing point and cold filter point, cannot be used, and limit the scope of application, so as to reduce the pressure difference between inside and outside. , prolong the service life, reduce the effect of wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

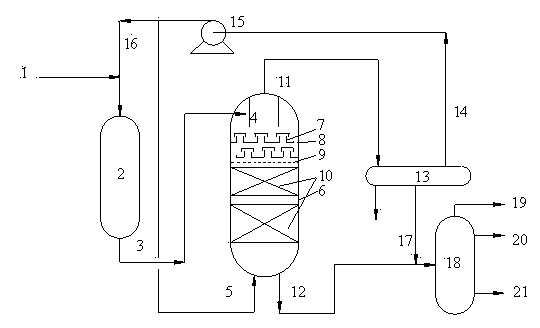

Image

Examples

Embodiment 1~2

[0036] The hydrofining catalyst is FF-36, the hydrodepressing catalyst is catalyst FDW-3, the process flow adopts the method of the present invention, the raw material oil is common commercially available soybean salad oil, and the reaction conditions and test results are shown in Table 3.

[0037] Table 2 Main properties of soybean oil

[0038] project Soybean oil Density(20℃) / g×cm -3 0.9198 Refraction, 20℃ 1.4742 Ash / wt% 0.018 C / H,wt% 79.13 / 11.87 S / N, μg·g -1 2.7 / 61.0 O, wt% 8.991 Freezing point / ℃ -12

[0039] Table 3 Test results

[0040] Example 1 Example 2 Process conditions catalyst FF-36 / FDW-3 FF-36 / FDW-3 Reaction pressure / MPa 8 8 Average reaction temperature / ℃ 330 / 330 330 / 330 Volumetric space velocity / h -1 1.0 / 0.8 1.0 / 0.6 Hydrogen oil volume ratio, v / v 1000 / 600 1000 / 600 Water generation rate, wt% 7.99 8.15 Yield of each fraction*, wt% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com