Polyvinyl-chloride extinction material and production method thereof

A matting material, polyvinyl chloride technology, applied in the chemical industry, can solve the problems of high gloss, not reaching the matt of rubber materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

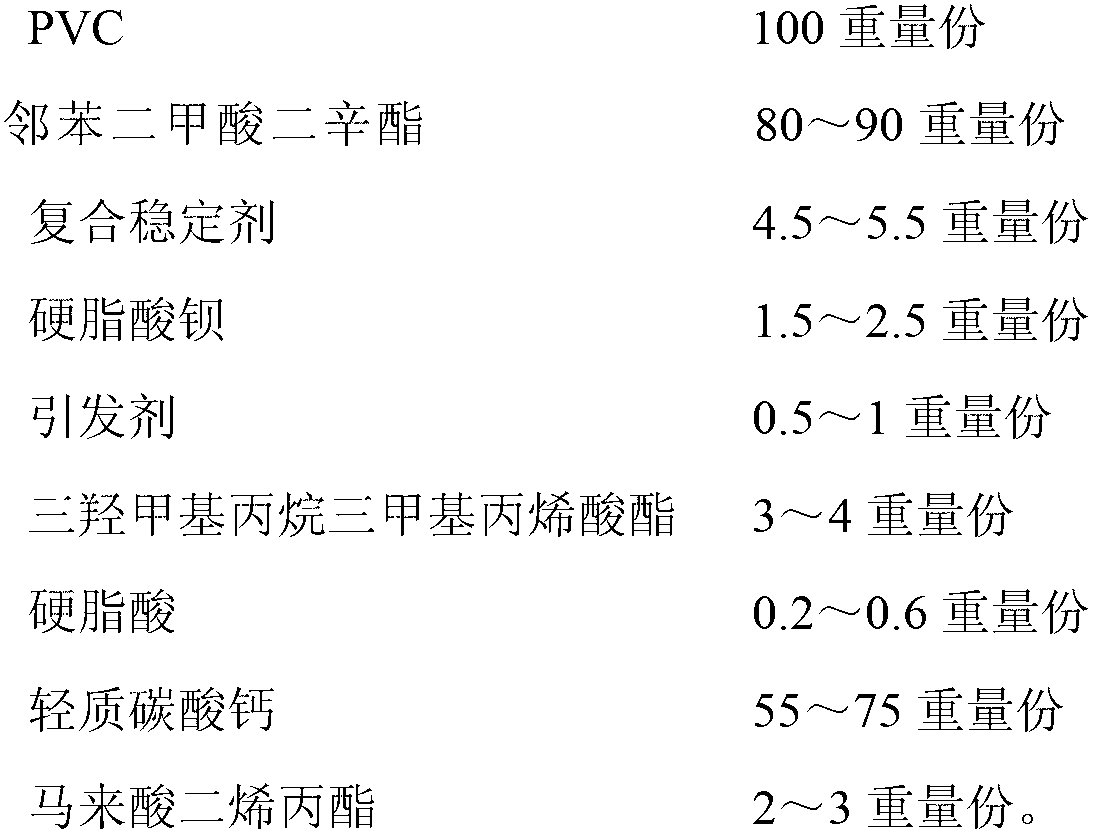

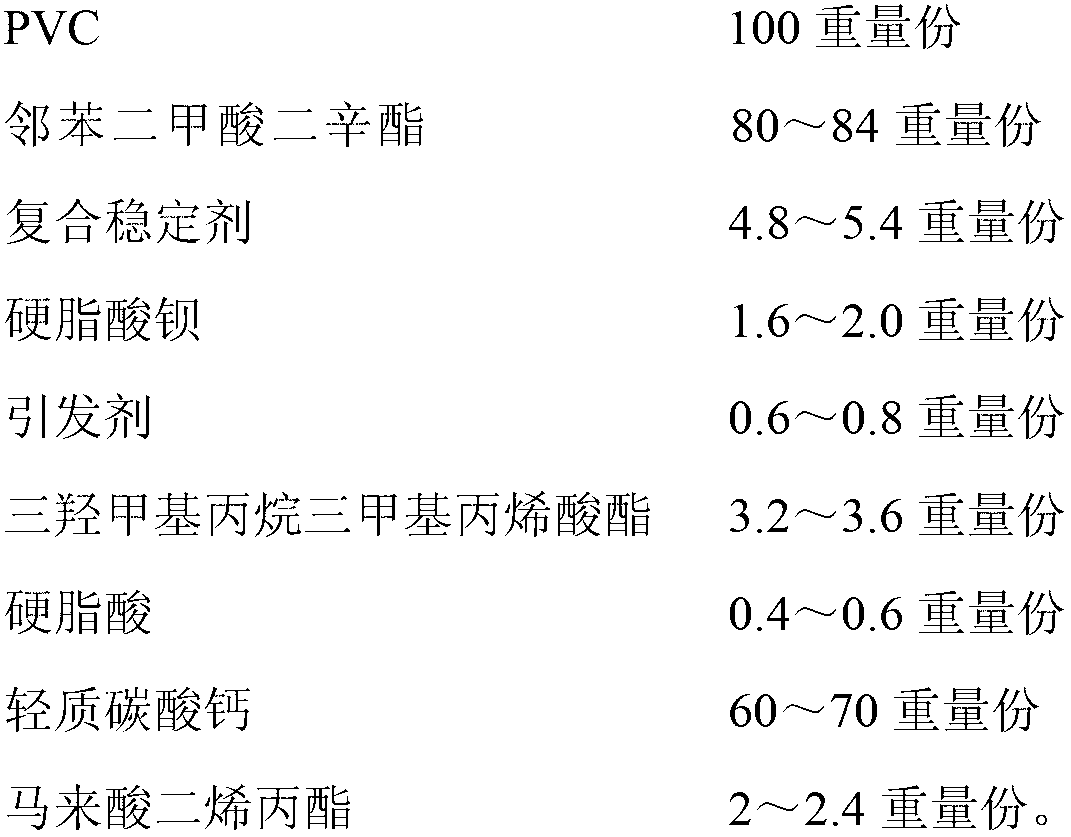

[0021]

[0022] production method:

[0023] 1. High-speed mixing: first mix PVC, DOP, compound stabilizer, barium stearate, stearic acid, and light calcium carbonate in a high-speed mixer at a high speed of 200 rpm for 8-9 minutes, then add the initiator For DCP, TMPTMA and DAM, stir at a low speed of 80 rpm for 1.5 to 2 minutes before discharging.

[0024] 2. Internal mixing: Mix the powder that has been cooled to 50-60°C in an internal mixer for 9-10 minutes, and the temperature used for mixing is 110°C.

[0025] 3. Reactive extrusion: Extrude and granulate in a twin-screw extruder, the screw speed is 60 rpm, and the temperature is set as shown in the table below:

[0026] area barrel zone 1 barrel zone 2 Barrel 3 zone Barrel 4 zone Barrel 5 zone Barrel 6 zone Barrel 7 zone nose

temperature 120~130℃ 130~140℃ 140~145℃ 150~160℃ 160~170℃ 160~170℃ 155~165℃ 140~150℃

[0027] The performance measurement of the polyvi...

Embodiment 2

[0030]

[0031] production method:

[0032] 1. High-speed mixing: first mix PVC, DOP, lead cyanurate compound stabilizer, barium stearate, stearic acid, light calcium carbonate in a high-speed mixer at a high speed of 200 rpm for 8-9 minutes Then add the initiators DCP, TMPTMA, and DAM, stir at a low speed of 80 rpm for 1.5 to 2 minutes, and then discharge.

[0033] 2. Internal mixing: Mix the powder that has been cooled to 50-60°C in an internal mixer for 9-10 minutes, and the temperature used for mixing is 120°C.

[0034] 3. Reactive extrusion: Extrude and granulate in a twin-screw extruder, the screw speed is 60 rpm, and the temperature is set as shown in the table below:

[0035] area barrel zone 1 barrel zone 2 Barrel 3 zone Barrel 4 zone Barrel 5 zone Barrel 6 zone Barrel 7 zone nose

temperature 120~130℃ 130~140℃ 140~145℃ 150~160℃ 160~170℃ 160~170℃ 155~165℃ 140~150℃

[0036] The performance measurement of t...

Embodiment 3

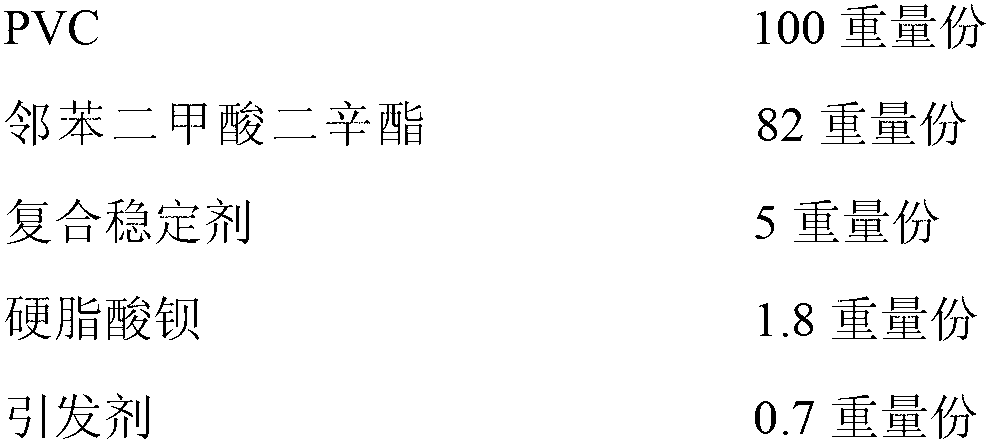

[0039]

[0040] production method:

[0041] 1. High-speed mixing: first mix PVC, DOP, lead cyanurate compound stabilizer, barium stearate, stearic acid, light calcium carbonate, and stir in a high-speed mixer at a high speed of 180 rpm for 8-9 minutes Then add the initiators DCP, TMPTMA, and DAM, stir at a low speed of 100 rpm for 1.5 to 2 minutes, and then discharge.

[0042] 2. Internal mixing: Mix the powder that has been cooled to 50-60°C in an internal mixer for 9-10 minutes, and the temperature used for mixing is 130°C.

[0043] 3. Reactive extrusion: Extrude and granulate in a twin-screw extruder, the screw speed is 60 rpm, and the temperature is set as shown in the table below:

[0044] area barrel zone 1 barrel zone 2 Barrel 3 zone Barrel 4 zone Barrel 5 zone Barrel 6 zone Barrel 7 zone nose

temperature 120~130℃ 130~140℃ 140~145℃ 150~160℃ 160~170℃ 160~170℃ 155~165℃ 140~150℃

[0045] The performance measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com