Automobile drive axle overall compound bulging device

A drive axle and bulging technology, applied in fluid pressure actuating devices, vehicle parts, transportation and packaging, etc., can solve the problems of easy cracking, difficult quality assurance, uneven width of flanging at the pipa bag, etc. The effect of position offset and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

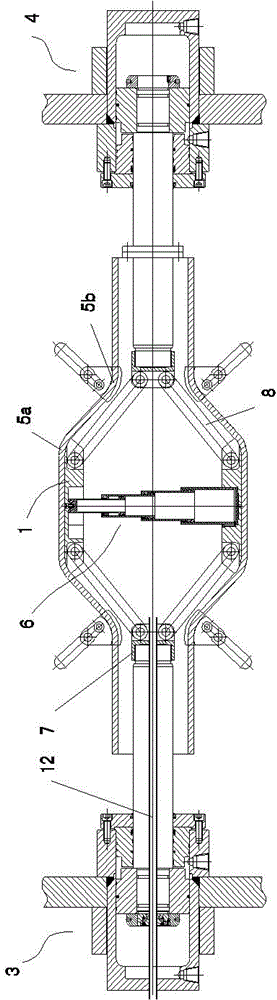

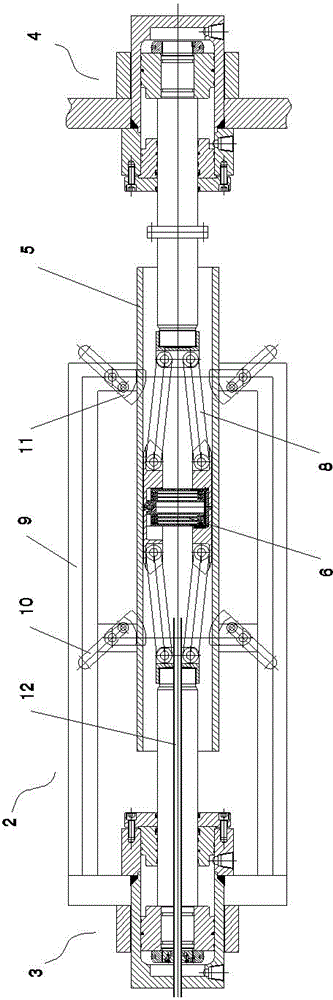

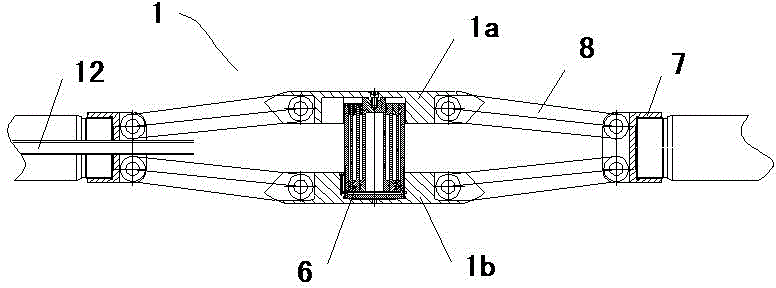

[0063] like figure 1 As shown, it is a structural schematic diagram of the first embodiment of the overall composite bulging device of the automobile drive axle of the present invention after the workpiece bulging deformation is completed, which is shown as a mechanical push rod type bulging method; figure 2 It is a structural schematic diagram of the integral composite bulging device of the automobile drive axle in this embodiment before the workpiece is bulging and deformed.

[0064] The integral composite bulging device of the automobile drive axle in this embodiment includes a bulging inner mold 1 , a bulging outer mold 2 and a bulging force generating device for applying bulging force to the bulging inner mold 1 . The bulging inner mold 1 includes an upper module 1a and a lower module 1b respectively matched with the upper and lower inner walls of the axle housing pipa bag 5a, and the two ends of the upper module 1a and the lower module 1b are hingedly connected by a li...

no. 2 example

[0080] like Figure 5 As shown, it is a structural schematic diagram of the second embodiment of the integral composite bulging device of the automobile drive axle of the present invention after the workpiece bulging deformation is completed, which is shown as an internal high-pressure bulging method; Image 6 It is a structural schematic diagram of the integral composite bulging device of the automobile drive axle in this embodiment before the workpiece is bulging and deformed.

[0081] like Figure 5 and Image 6 As shown, the two thrust devices in this embodiment are the thrust hydraulic cylinder 3 and the thrust hydraulic cylinder 4 respectively located at both ends of the bulging inner mold 1 and used to provide the bulging thrust. The thrust hydraulic cylinder 3 and the thrust hydraulic cylinder 4 respectively expand to Hydraulic thrust is applied to both ends of the inner mold. The pressure generating device of this embodiment is at least one multi-stage internal hig...

no. 3 example

[0089] like Figure 9 As shown, it is a structural schematic diagram of the third embodiment of the overall composite bulging device of the automobile drive axle of the present invention after the bulging deformation of the workpiece is completed, which is shown as an internal high pressure flow type bulging method; Figure 10 It is a structural schematic diagram of the integral composite bulging device of the automobile drive axle in this embodiment before the workpiece is bulging and deformed.

[0090] The integral composite bulging device of the automobile drive axle in this embodiment includes a bulging inner mold 1 , a bulging outer mold 2 and a bulging force generating device for applying bulging force to the bulging inner mold 1 . The bulging inner mold 1 includes an upper module 1a and a lower module 1b respectively matched with the upper and lower inner walls of the axle housing pipa bag 5a, and the two ends of the upper module 1a and the lower module 1b are hingedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com