Crispy rice-type healthcare feed for rabbits and method for preparing same

A kind of rice cooker type, feed technology, applied in animal feed, animal feed, application and other directions, can solve the problems of drug residues in rabbit meat, affecting the safety of meat food, etc., to reduce the amount of excrement, improve digestion and utilization efficiency, and reduce feed consumption By the effect of the ratio down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

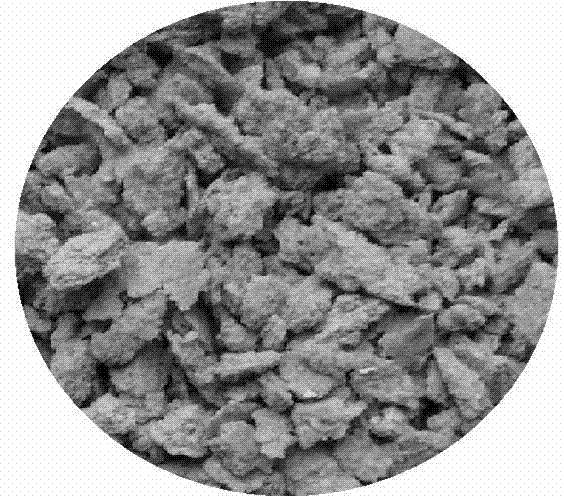

Image

Examples

Embodiment 1

[0032] 1600g soybean meal

[0033] Corn 1800g

[0034] Bran 1600g

[0035] Dried ginseng stems and leaves 300g

[0036] Grass Powder 4500g

[0037] Rabbit premix 250g

[0038] Production process: The above raw materials are pulverized and mixed with a two-way auger mixer. The coefficient of variation (c.v)% of the mixing uniformity is required to be 7.58; after mixing evenly, it is matured by an extrusion extruder, and the instantaneous temperature of curing is 115°C and the pressure is 1.5. Mp, hot steam flow rate 48ml / min; spray the active substance again, the sprayed mist liquid flow rate is 79ml / min; pass through two layers of grading sieves, the first layer has a 5.0mm sieve hole, the second layer has a 3.0mm sieve hole, and passes through the second layer The sieved fine powder is returned to the feeding bin of the extrusion extruder through the elevator; the sieve on the first layer is crushed by a low-speed pulverizer after deceleration so that it all passes throug...

Embodiment 2

[0041] 1400g soybean meal

[0042] Corn 1600g

[0043] Bran 1400g

[0044] Dried ginseng stems and leaves 200g

[0045] Grass powder 4000g

[0046] Rabbit premix 200g

[0047] Production process: The above raw materials are crushed and mixed with a two-way auger mixer. The coefficient of variation (c.v)% of the mixing uniformity is required to be 8.0; after mixing evenly, it is matured by an extrusion extruder, and the instantaneous temperature of curing is 105°C and the pressure is 1.5. Mp, hot steam flow rate 40ml / min; spray the active substance again, the sprayed mist liquid flow rate is 70ml / min; pass through two layers of grading sieves, the first layer has a 5.0 mm sieve hole, the second layer has a 3.0 mm sieve hole, and passes through the second layer The sieved fine powder is returned to the feeding bin of the extrusion extruder through the elevator; the sieve on the first layer is crushed by a low-speed pulverizer after deceleration so that it all passes through ...

Embodiment 3

[0050] 1800g soybean meal

[0051] Corn 2000g

[0052] Bran 1800g

[0053] Dried ginseng stems and leaves 400g

[0054] Grass powder 5000g

[0055] Rabbit premix 300g

[0056] Production process: The above raw materials are pulverized and mixed with a two-way auger mixer. The coefficient of variation (c.v)% of the mixing uniformity is required to be 8.0; after mixing evenly, it is matured by an extrusion extruder, and the instantaneous temperature of curing is 120°C and the pressure is 1.58. Mp, hot steam flow rate 49ml / min; spray the active substance again, the sprayed mist liquid flow rate is 80ml / min; pass through two layers of grading sieves, the first layer has a 5.0mm sieve hole, the second layer has a 3.0mm sieve hole, and passes through the second layer The sieved fine powder is returned to the feeding bin of the extrusion extruder through the elevator; the sieve on the first layer is crushed by a low-speed pulverizer after deceleration so that it all passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com