Target shape optimization method for aspherical optical element in conventional processing stage

A technology of optical components and traditional processing, applied in optical components, optics, instruments, etc., can solve the problems of excessive surface error of intermediate frequency, excessive removal of workpiece surface, large deviation between spherical surface and aspherical surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

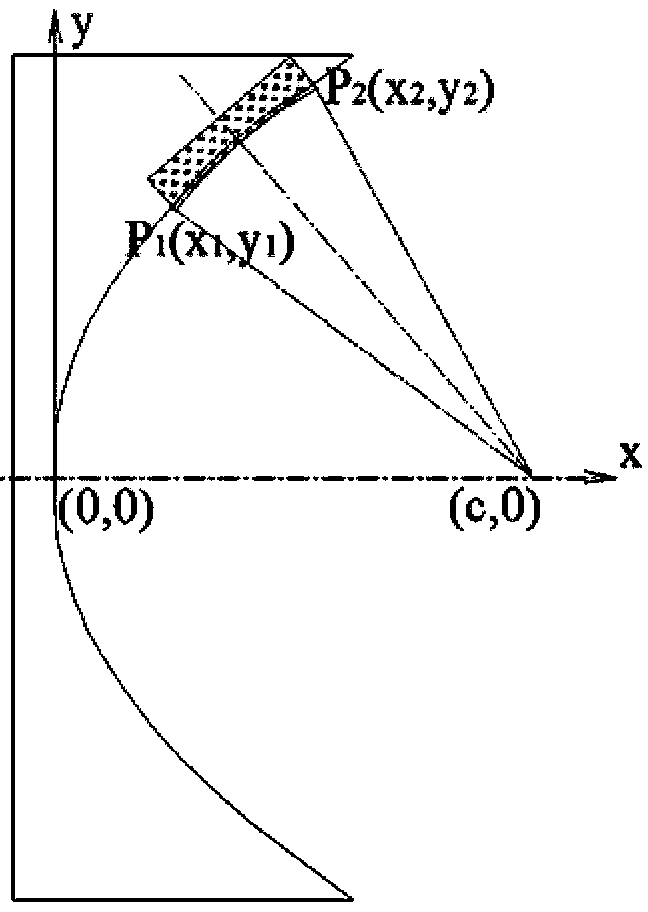

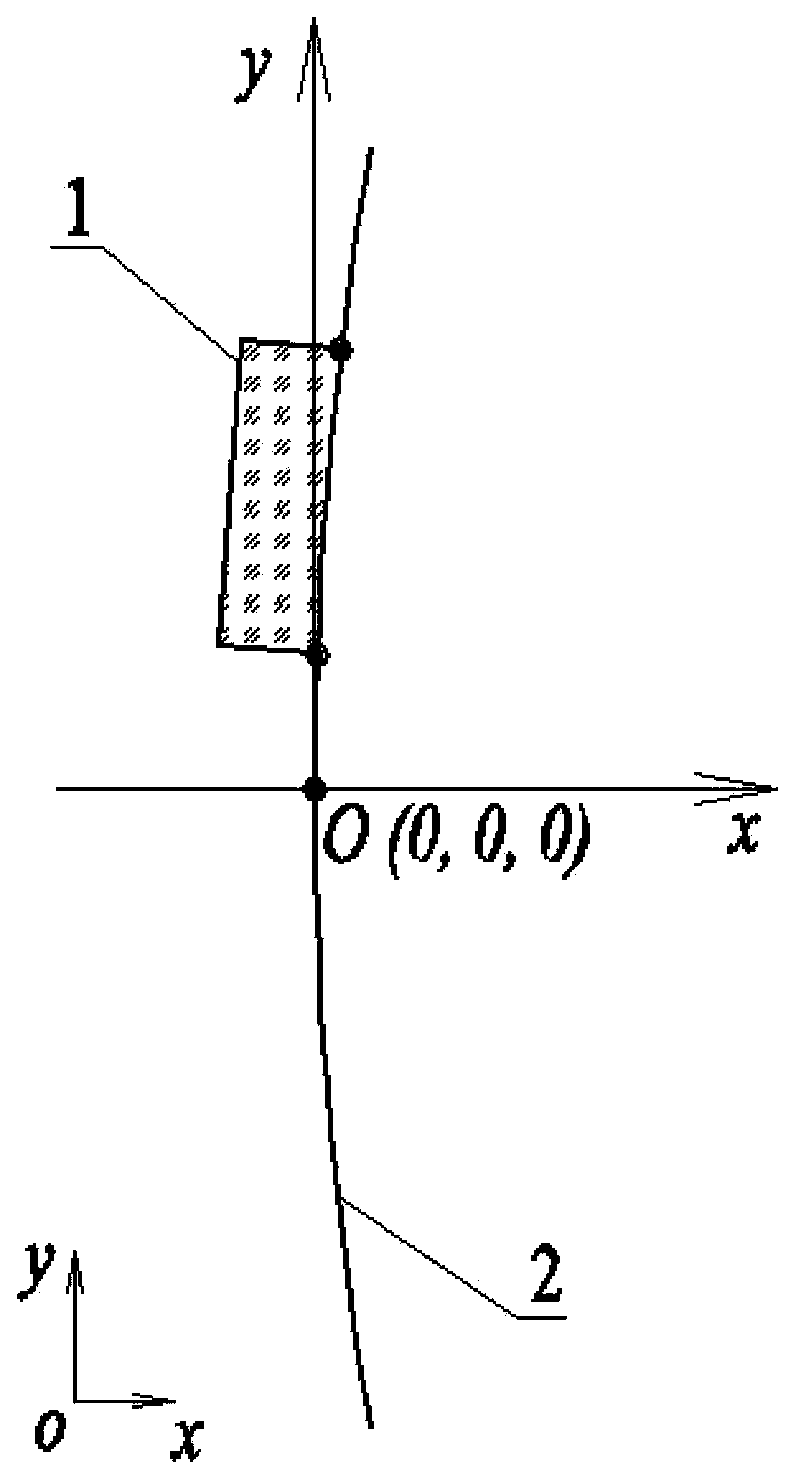

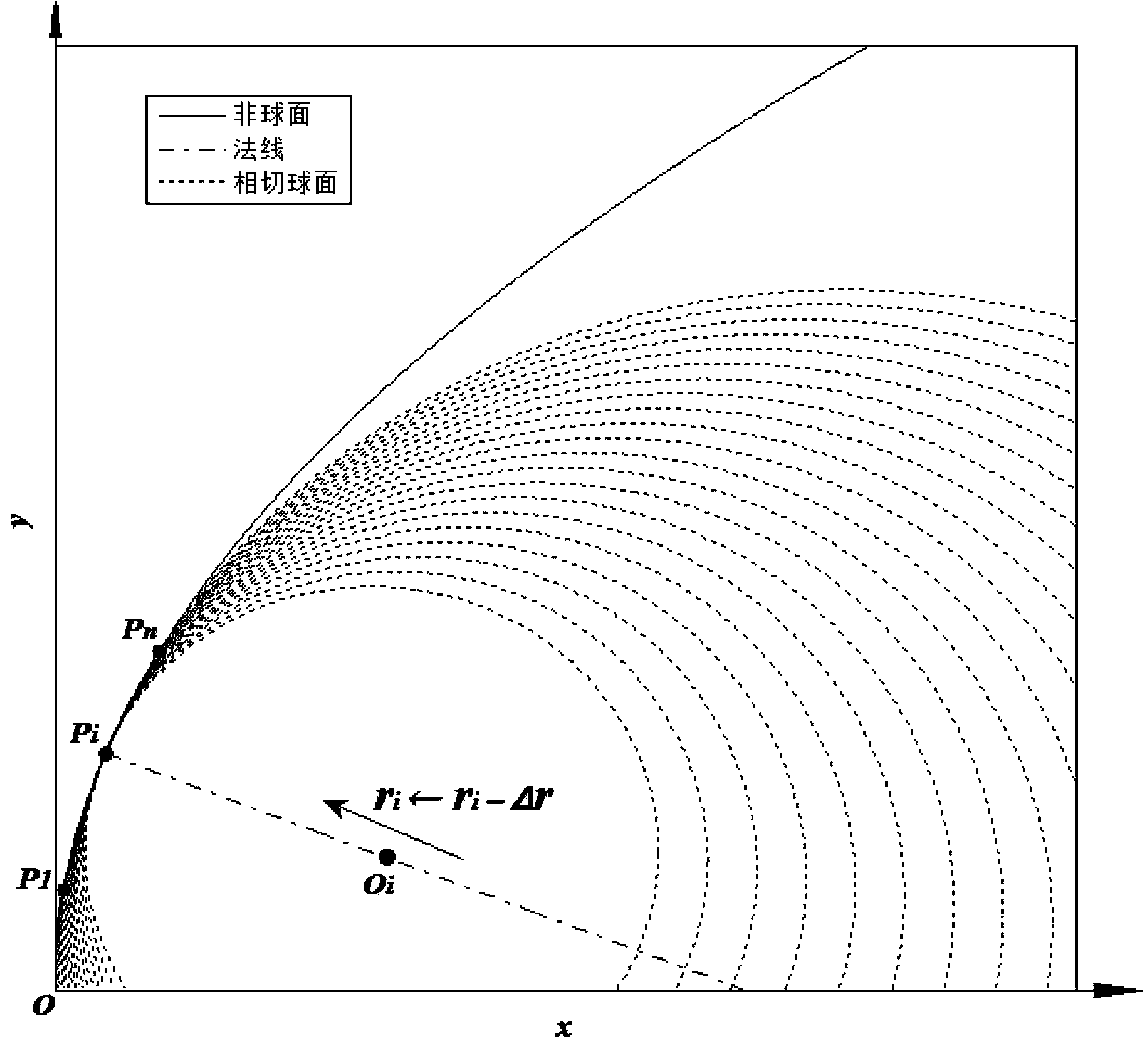

[0059] Such as figure 2 , image 3 As shown, the concave off-axis parabolic mirror 1 is located on the paraboloid of revolution 2 . P 1 P n is the intercept curve obtained by intersecting it with the xoy plane, O i point at P i point on the normal. figure 2 The positional relationship between the concave off-axis paraboloid mirror 1 and the revolution paraboloid 2 is shown as a whole. Concave off-axis parabolic mirror 1 equation is y 2 +z 2 =2400x, y∈[42,143], z∈[-50,50], the unit is millimeter.

[0060] Laser interferometers are usually used to measure the surface shape of workpieces. Since the resolution of the interferometer’s lateral measurement is 0.1 to 0.2 mm, when discretizing the surface equation in the computer, the y direction of two adjacent points in the data point matrix The distances in and z directions are both set to 0.1 mm, so that Δr=0.1 mm.

[0061] The value of n and m determines the level of calculation accuracy, here select n=1000, m=1000×100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com