Forced synchronization circular vibrating screen device

A circular vibrating screen and forced synchronization technology, which is applied in the direction of vibration suppression adjustment, filter screen, spring/shock absorber, etc., can solve the problems of heavy weight of the vibrator, lack of heat dissipation structure, insufficient power, etc., to reduce the weight of the casing, Guarantee normal operation and avoid failure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

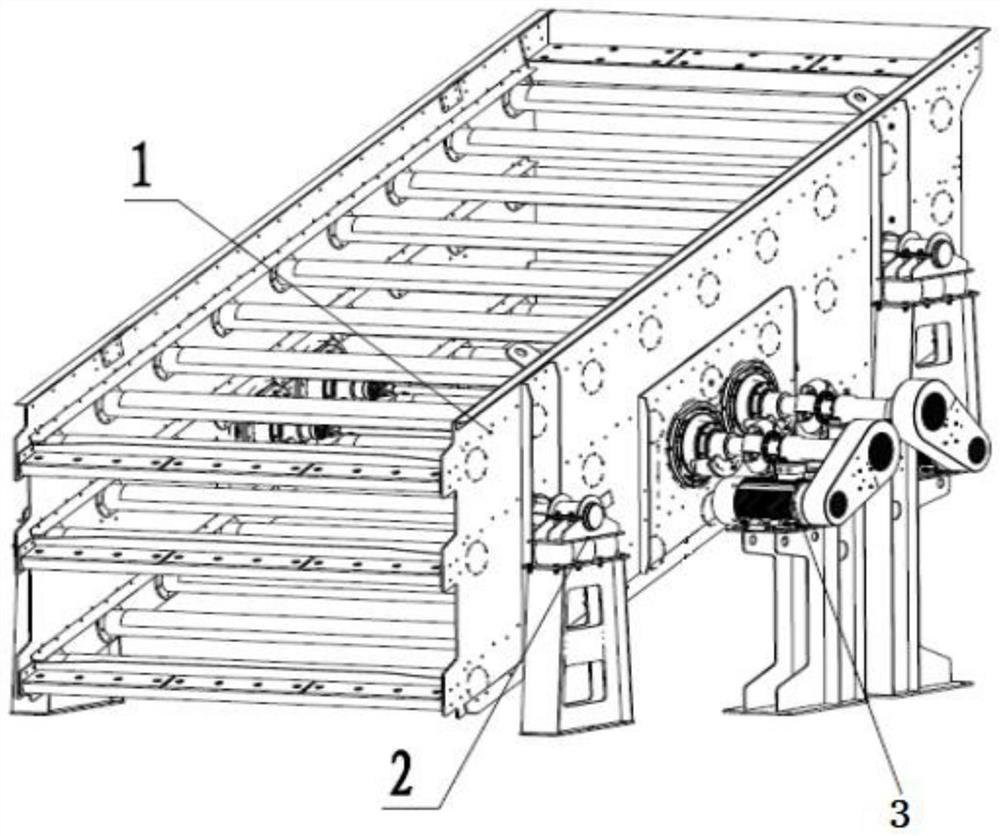

[0043] A forced synchronous circular vibrating screen device, comprising a screen box assembly 1, a vibration excitation assembly 3 and a support damping assembly 2;

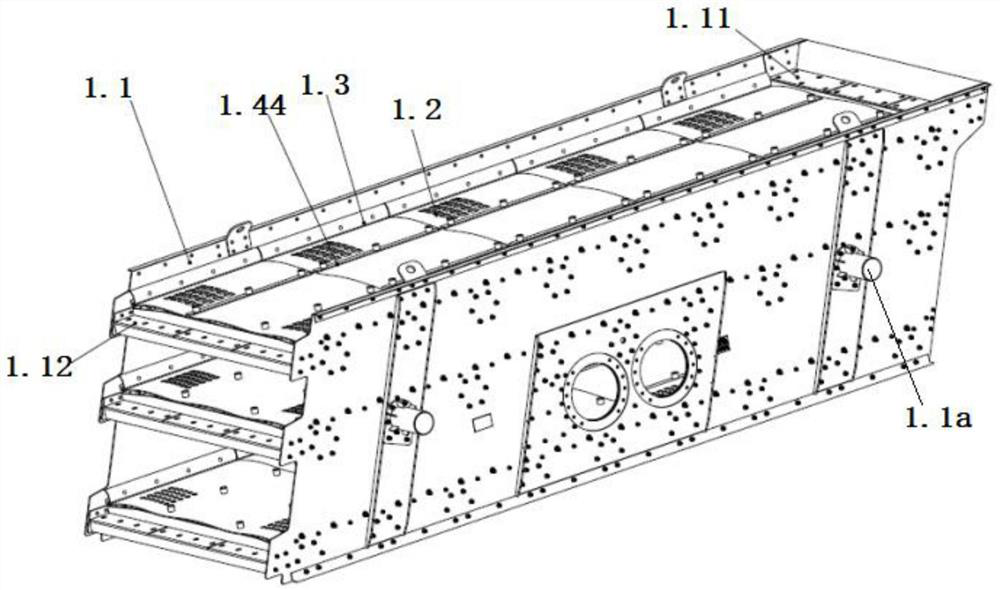

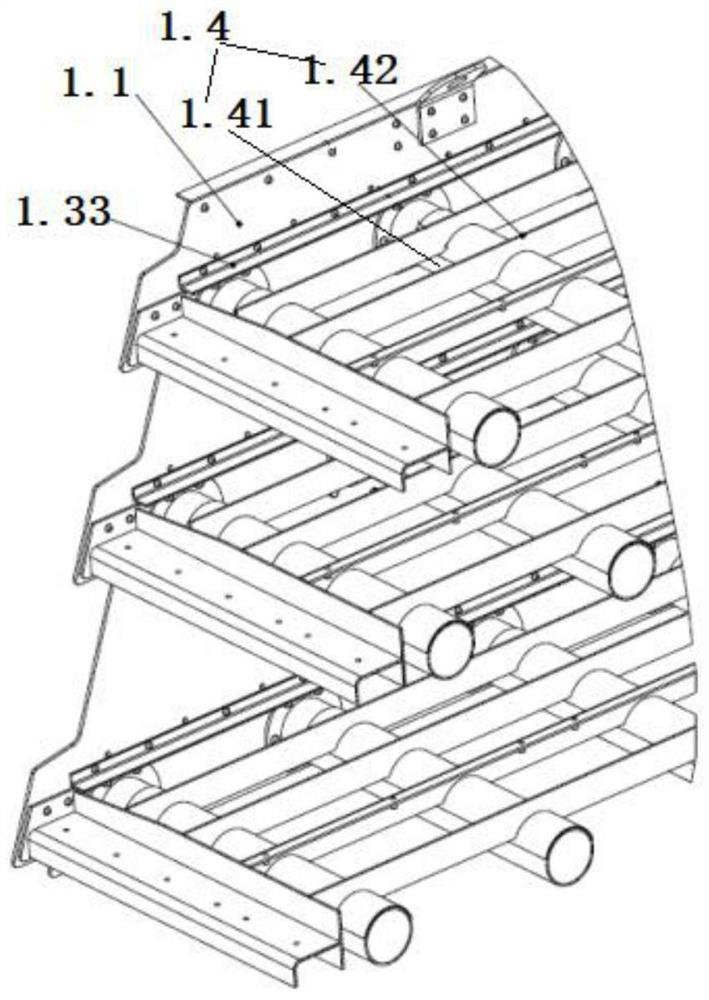

[0044] The screen box assembly 1 of this embodiment includes a screen frame 1.1, a screen mesh 1.2, a screen mesh tensioning structure 1.3 and multiple sets of beam structures 1.4;

[0045] The multiple sets of beam structures 1.4 in this embodiment are arranged in the screen frame 1.1 in parallel along the vertical direction, and can form multiple sets of support structures that are parallel up and down in the screen frame 1.1. This embodiment illustrates three sets of beam structures 1.4, which can form three sets of support structures. Support structure (that is, to form a three-layer structure); the beam structure 1.4 includes multiple sets of beams 1.41 and multiple sets of longitudinal beams 1.42 (the specific number is selected according to the actual situation), and multiple sets of beams 1.41 (column) ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com