Expansion valve

A technology of expansion valve and valve core, applied in the field of expansion valve, can solve problems such as refrigerant pressure loss, and achieve the effect of reducing pressure loss, avoiding the increase of manufacturing cost, and omitting sealing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

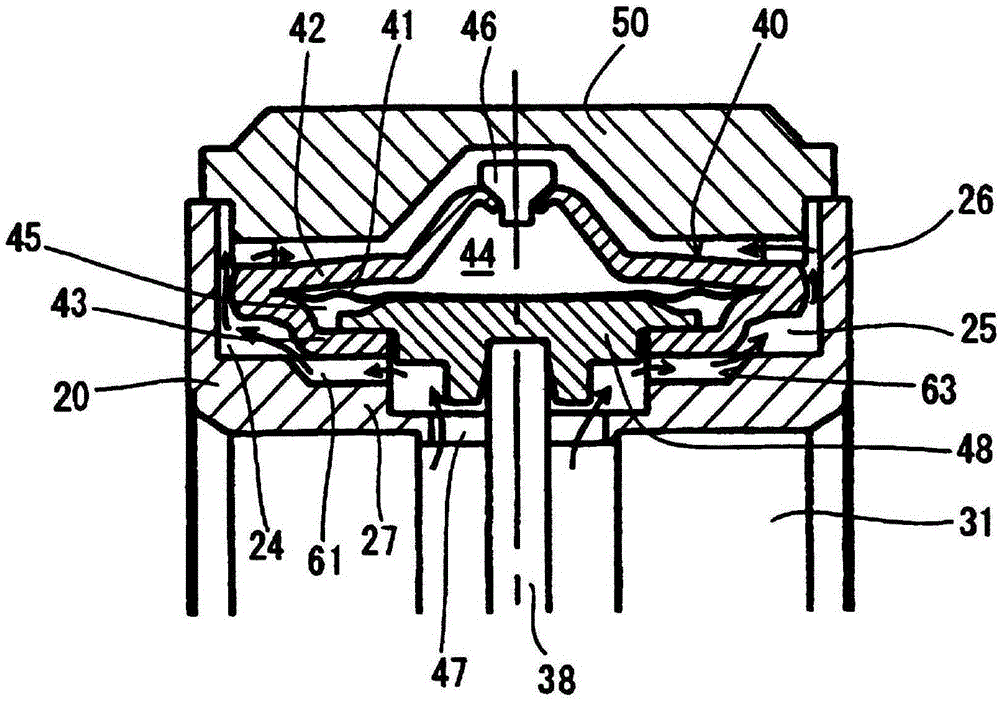

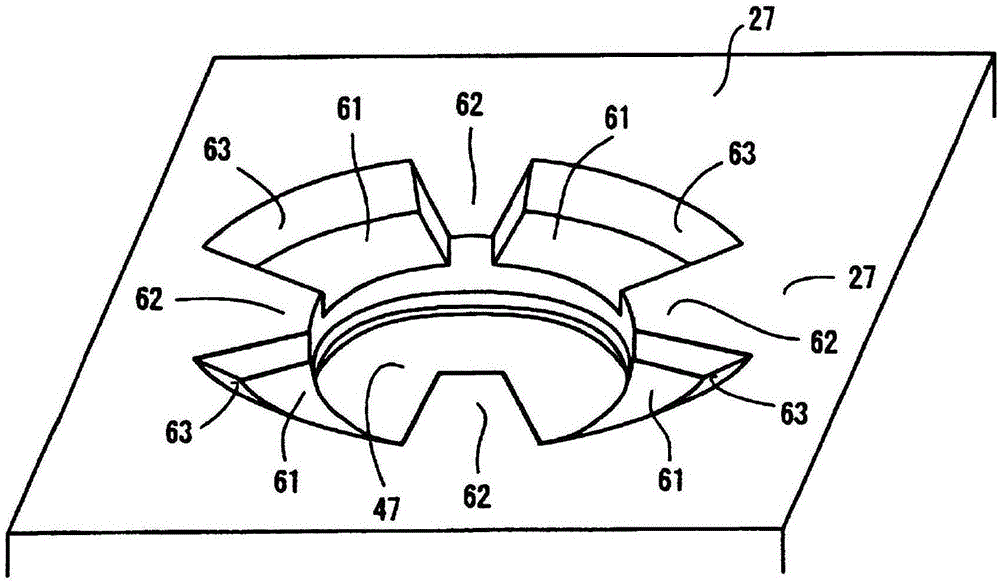

[0030] Next, embodiments of the expansion valve of the present invention will be described with reference to the drawings. figure 1 The expansion valve 1 shown is used in the refrigeration cycle of air conditioners such as automobiles. Inside a square columnar valve body 20 made of aluminum or the like, a first passage 30 is formed at a distance from each other up and down. The first passage 30 is The high-pressure side passage through which the refrigerant passes from the refrigerant outlet of the condenser to the refrigerant inlet of the evaporator through the accumulator; and the second passage 31, which is from the refrigerant outlet of the evaporator to the condenser The path through which the refrigerant at the refrigerant inlet passes.

[0031] A valve chamber 32 and an orifice 33 for adiabatically expanding the refrigerant are formed in the middle of the first passage 30 . In the valve chamber 32 , a spherical valve element 34 is disposed in contact with and separate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com