Automatic light leakage degree and closed gap detector of three-station piston ring and calibrating block thereof

A closed gap and piston ring technology, which is applied in the field of automatic detection devices for piston rings, can solve the problems of inability to realize automatic detection, inapplicability of small and medium-sized piston rings, and limitation of detection efficiency, and achieve high reliability, precise detection and control principles, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The three-station piston ring light leakage and closed gap automatic detector and its calibration block of the present invention will be described in detail below in combination with the embodiments and the accompanying drawings.

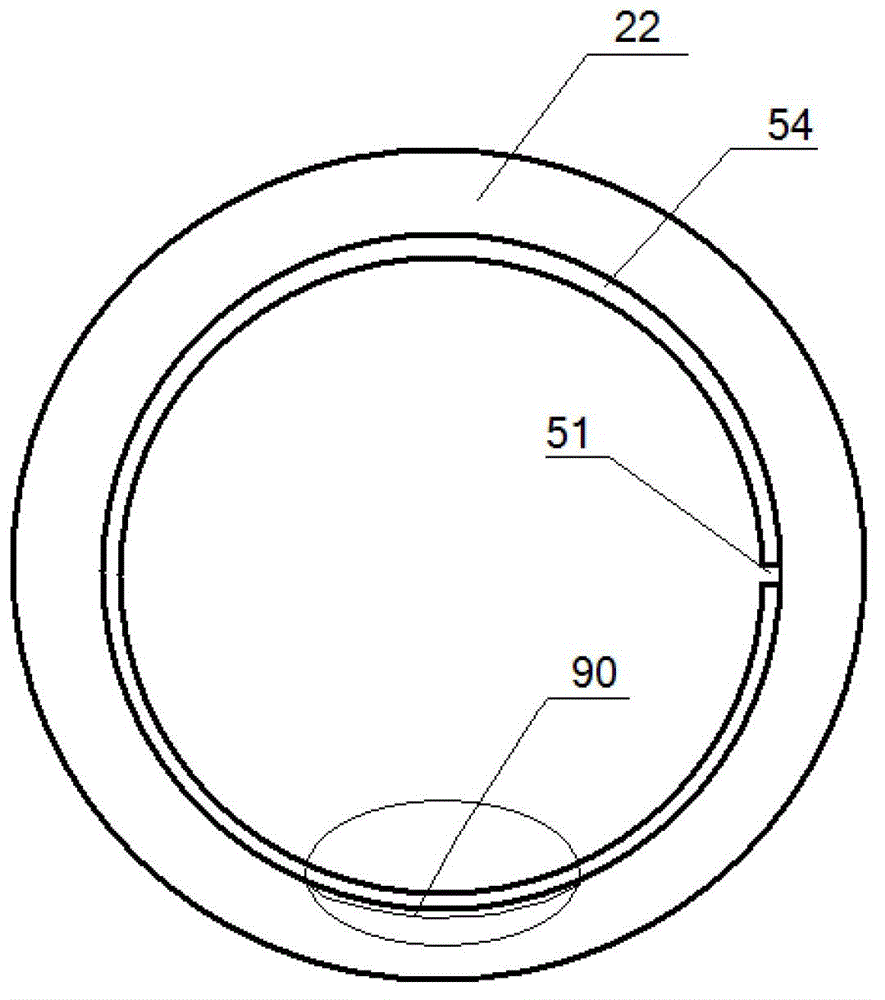

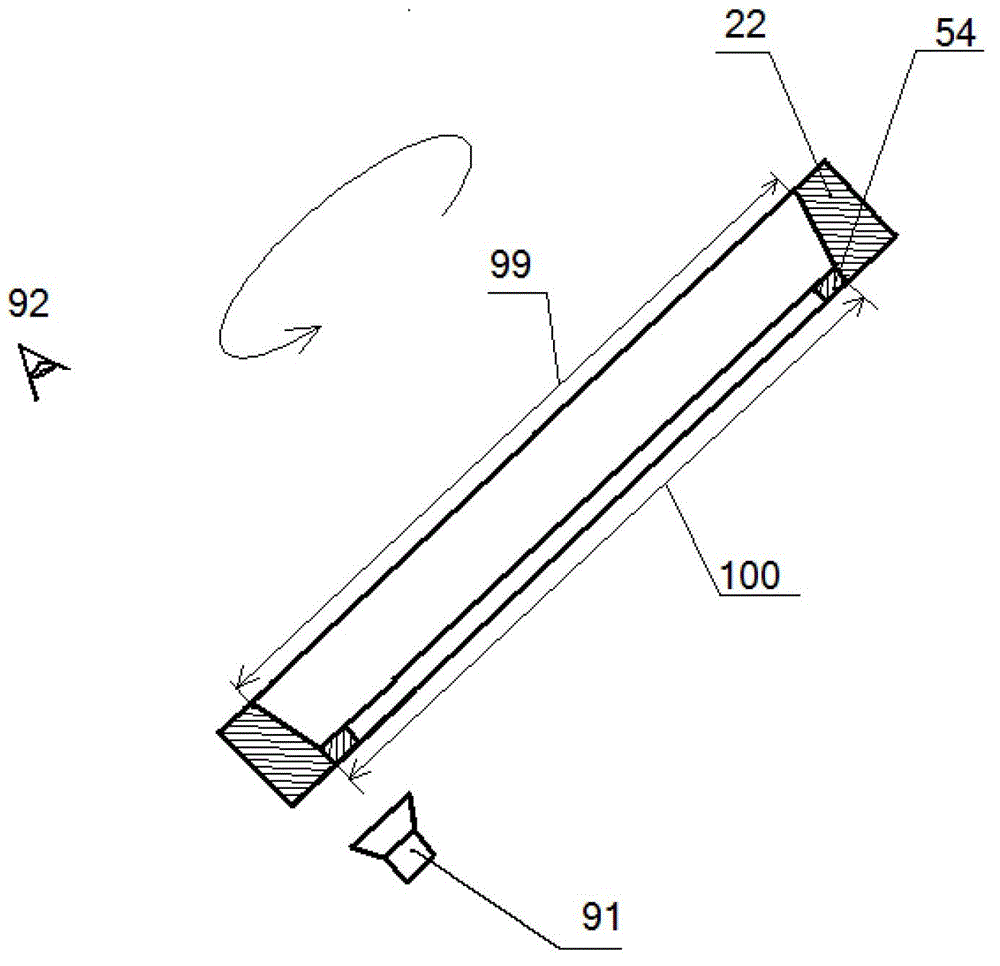

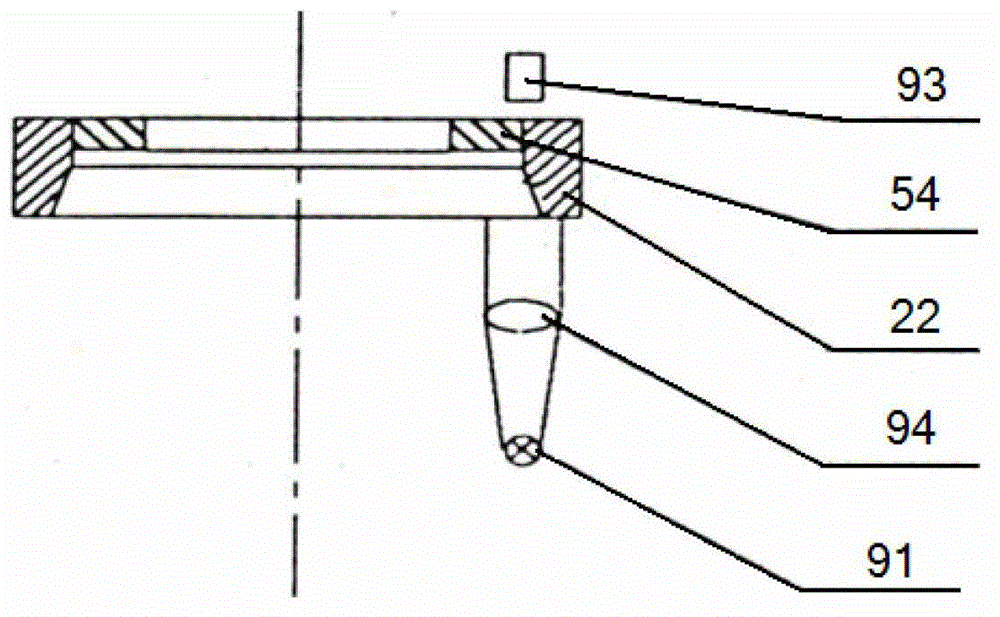

[0074] The three-station piston ring light leakage and closed gap automatic detector and its calibration block of the present invention integrate an original technology for the reality of the measured object: the end-face reverse deduction positioning technology to ensure the consistency of the combined state of the piston ring-ring gauge , Self-adaptive end-face lamination technology, piston ring closed gap fixed object distance imaging measurement technology, fixed object distance imaging calibration technology, light leakage CCD sensor positive incident low-light detection technology, visual inspection without blind spot scanning technology, ring gauge static, CCD sensor Synchronous rotation technology with the shading plate; and the existi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com