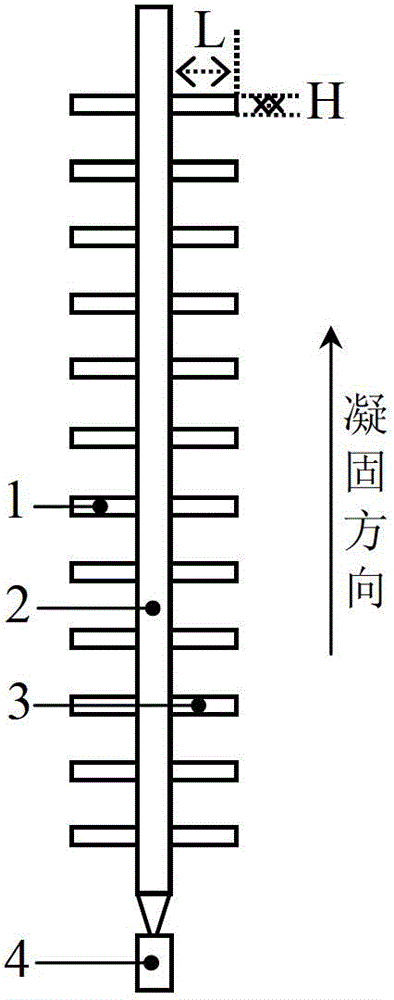

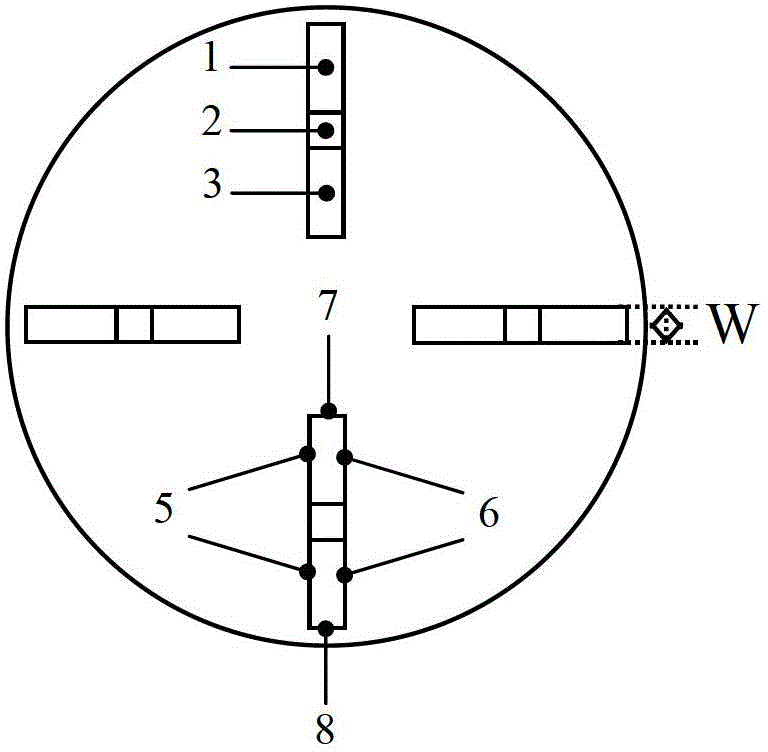

Method for evaluating temperature field distribution in orientated solidification process

A technology of directional solidification and temperature field, which is applied in the field of investment casting, can solve the problems of difficult to accurately reflect the symmetry of temperature field distribution, and achieve the effect of easy popularization and application, low cost and easy casting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

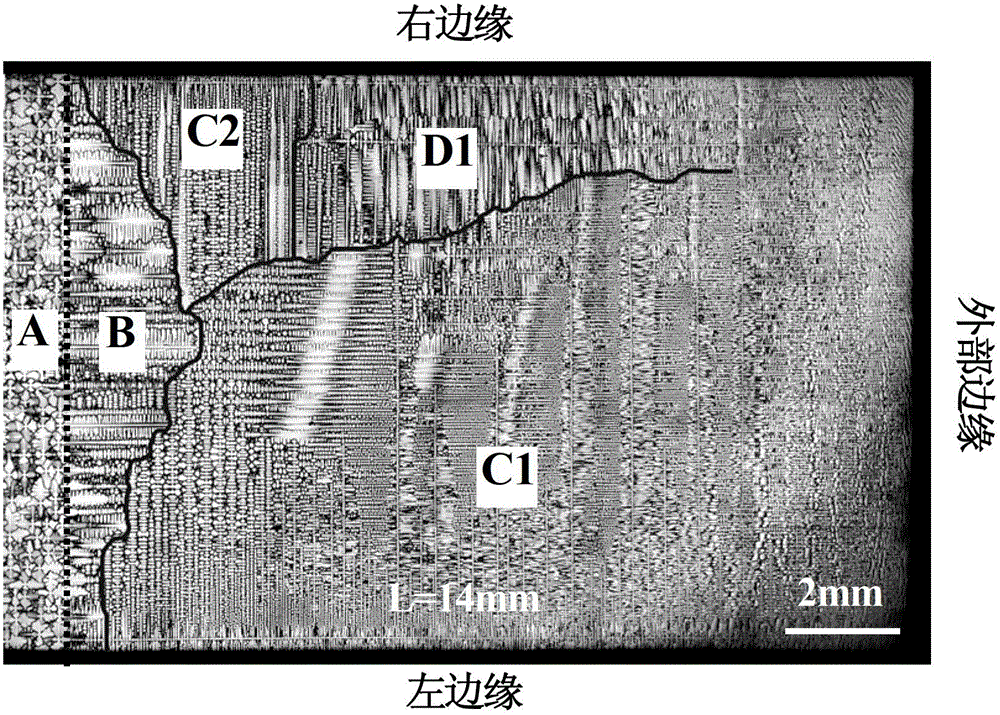

[0038] figure 2 It is the dendrite growth mode in the bottom cross-section of the fifth outer platform (from bottom to top) of SRR99 alloy. The original dendrites in the leaf body branched along two paths in the platform. Path 1: A-B-C1-D1; Path 2: A-B-C2. A refers to the area of the original dendrite in the leaf body; B refers to the branching area of the secondary dendrite arm of the original dendrite in the platform; C1 refers to the tertiary branching area perpendicular to the left edge of the platform; C2 refers to the branching area perpendicular to the right edge of the platform Tertiary branching area; D1 refers to the fourth branching area from the left and outer edges of the platform. It can be seen that the number and area of the branch regions corresponding to the two branch paths are different. The number of branched regions along path 1 is small and the area of branched regions is small, which indicates that the temperature field distribution around th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com