Low-yield ratio and high-strength stirrup provided with bainite structure and used for buildings and production process

A low-yield-strength ratio, bainite technology, applied in the field of low-yield-strength-ratio bainite structure and high-strength construction stirrups and production processes, can solve problems such as easy fracture, improve seismic performance, and shorten heat treatment time. , The effect of high strength of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0024] A ferrite plus pearlite ф8 hot-rolled crescent-ribbed disc, the chemical composition is: C: 0.21%, Si: 0.55%, Mn: 1.15%, P: 0.020%, S: 0.015%, and the rest is Fe and impurities. The coil is set out, descaled, straightened, drawn, heated to 960°C, water-cooled to 350°C for 3 seconds, kept warm for 40 seconds, cooled to room temperature, sheared, and coiled to obtain a finished steel bar.

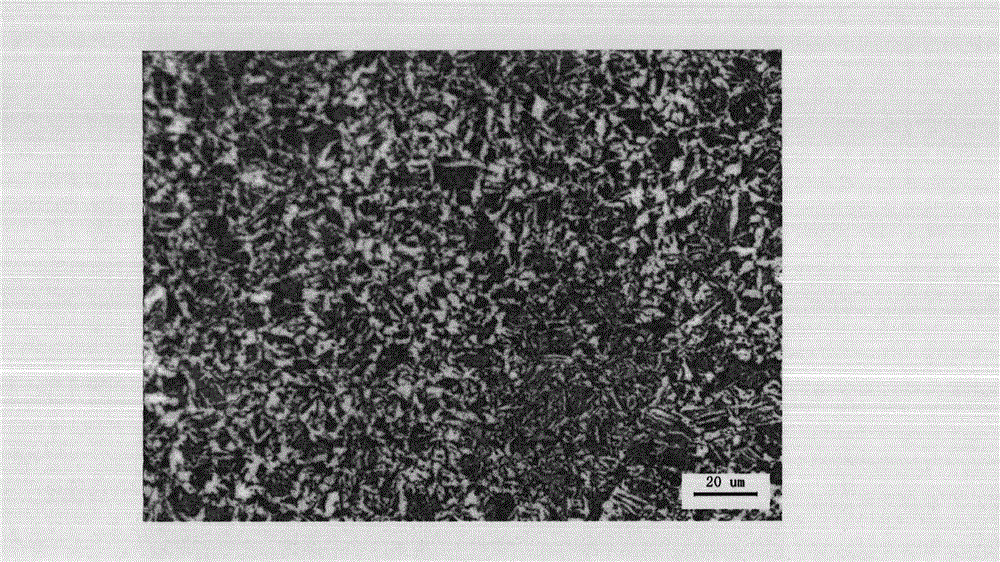

[0025] The yield strength of the steel bar is 956MPa, the tensile strength is 1180MPa, the yield strength ratio is 0.81, the elongation after breaking is A: 18%, the total elongation under the maximum force is Agt: 5.6%, and there is no crack at the bend after bending 180 degrees (the bending radius R is the nominal 3 times the diameter) to obtain a ferrite plus bainite structure (Fig. 1).

example 2

[0027] A ferrite plus pearlite ф5.5 hot-rolled smooth disc, the chemical composition is: C: 0.30%, Si: 0.68%, Mn: 1.23%, P: 0.020%, S: 0.018%, and the rest is Fe and Impurities. The disc is made into a spiral groove after unwinding-descale-drawing-straightening-drawing-heating to 1050°C-water cooling to 400°C for 3 seconds-holding for 40 seconds-cooling to room temperature-shearing-winding , to obtain finished steel bars.

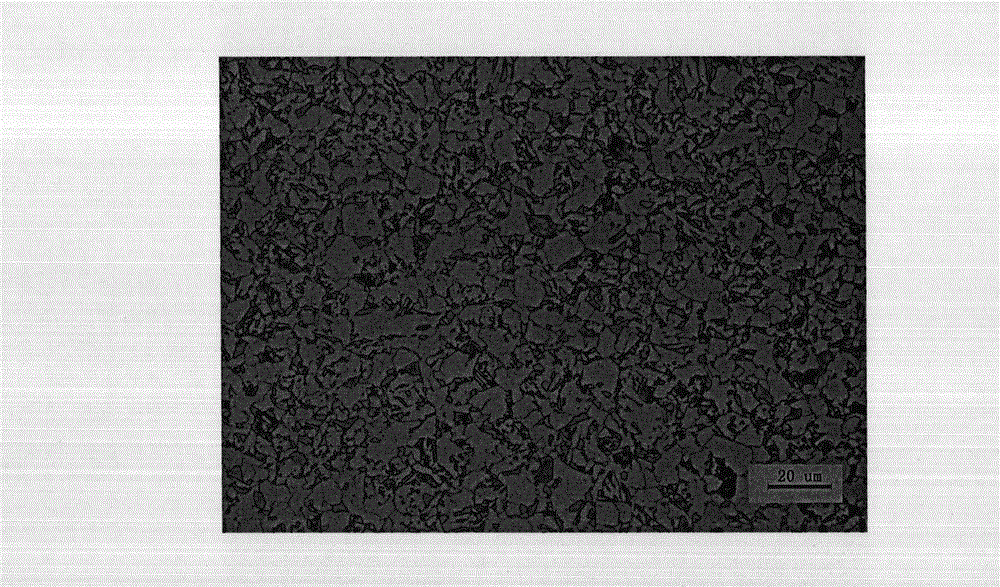

[0028] The yield strength of the steel bar is 1116MPa, the tensile strength is 1313MPa, the yield strength ratio is 0.85, the elongation A after breaking is 16.5%, the total elongation Agt under the maximum force is 5.0%, and there is no crack at the bend after bending 180 degrees (the bending radius R is the nominal 3 times the diameter) to obtain a ferrite plus bainite structure (Fig. 2).

[0029] Description of drawings: Figure 1 is Reinforcement Microstructure

[0030] Figure 2 is Steel microstructure diagram.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com