Temporary protective paint composition for water base environment-friendly lens and preparation method of composition

A temporary protection and environmental protection technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of hindering the application of water-based coatings, unable to be coated, etc., to achieve easy peeling of the whole piece, low price, good light transmittance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

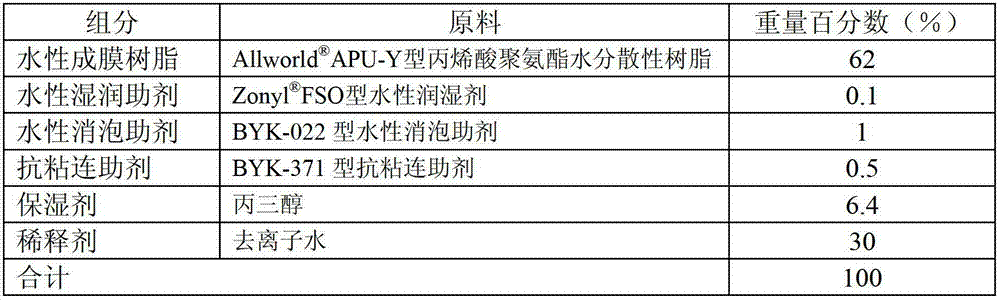

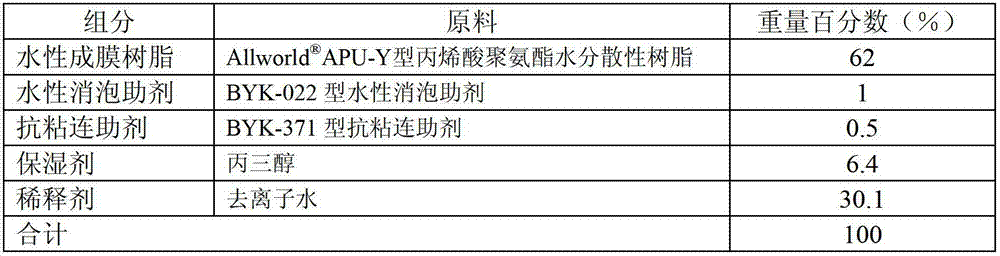

[0014] Components and Raw Materials

[0015]

[0016] Preparation

[0017] First, add the water-based film-forming resin and the water-based wetting aid into the container, and stir for 2 hours with a high-speed disperser at a speed of 500 rpm, then add the water-based defoaming aid and anti-blocking additive in turn in the container, and then use the high-speed disperser. Stir at a speed of 500rpm for 1 hour, then add humectants and diluents in turn into the container, stir with a high-speed disperser at a speed of 500rpm for 10-15 minutes, and filter to obtain the composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com