Overweight main girder turnover device and turnover method

A technology of large slab girders and slab girders, which is applied in the field of turning over large slab girders, can solve problems such as unsatisfactory driving capacity, adverse effects of driving, and large inertial impacts, so as to save turning time, save costs, and reduce effect of load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

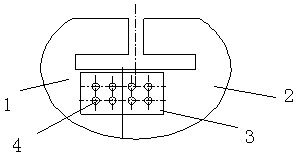

[0015] Such as figure 1 and figure 2 Shown is an oversized slab girder turning device, the turning device is arranged at one end of the slab girder and includes two semicircular 1, 2 segments formed by splicing together, the two semicircular 1, 2 The arcs have different lengths and are connected by connecting plates 3 and bolts 4, and the chords are provided with holes matching the cross-sectional shape of the super heavy plate girder 5.

[0016] The method for turning over a super heavy slab girder includes the turning device and the following steps:

[0017] Step 1, buckle the two rounds 1, 2 on the lower flange of the super heavy plate girder 5 member, and then use the bolts used in conjunction with the connecting plate 3 to fasten, the turning device is in contact with the web of the plate girder member The parts are clamped but not spot welded;

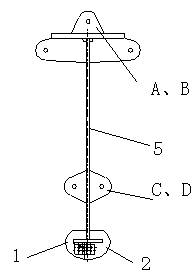

[0018] Step 2, setting hanging points A, B and C, D respectively on one end and the other side of the super heavy plate gir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com