Self-gravity effect-based marine diesel engine connecting rod turning over device and method

A marine diesel engine and self-gravity technology, which is applied in the manufacturing process of marine diesel engines and the field of turning over devices for connecting rods of marine diesel engines, can solve the problems of irregular shape of connecting rods of marine diesel engines, difficulty in turning over the connecting rods, complex and irregular shapes, etc., and achieve Good wear resistance, simple structure and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The device and method for turning over the connecting rod of a marine diesel engine according to the present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples.

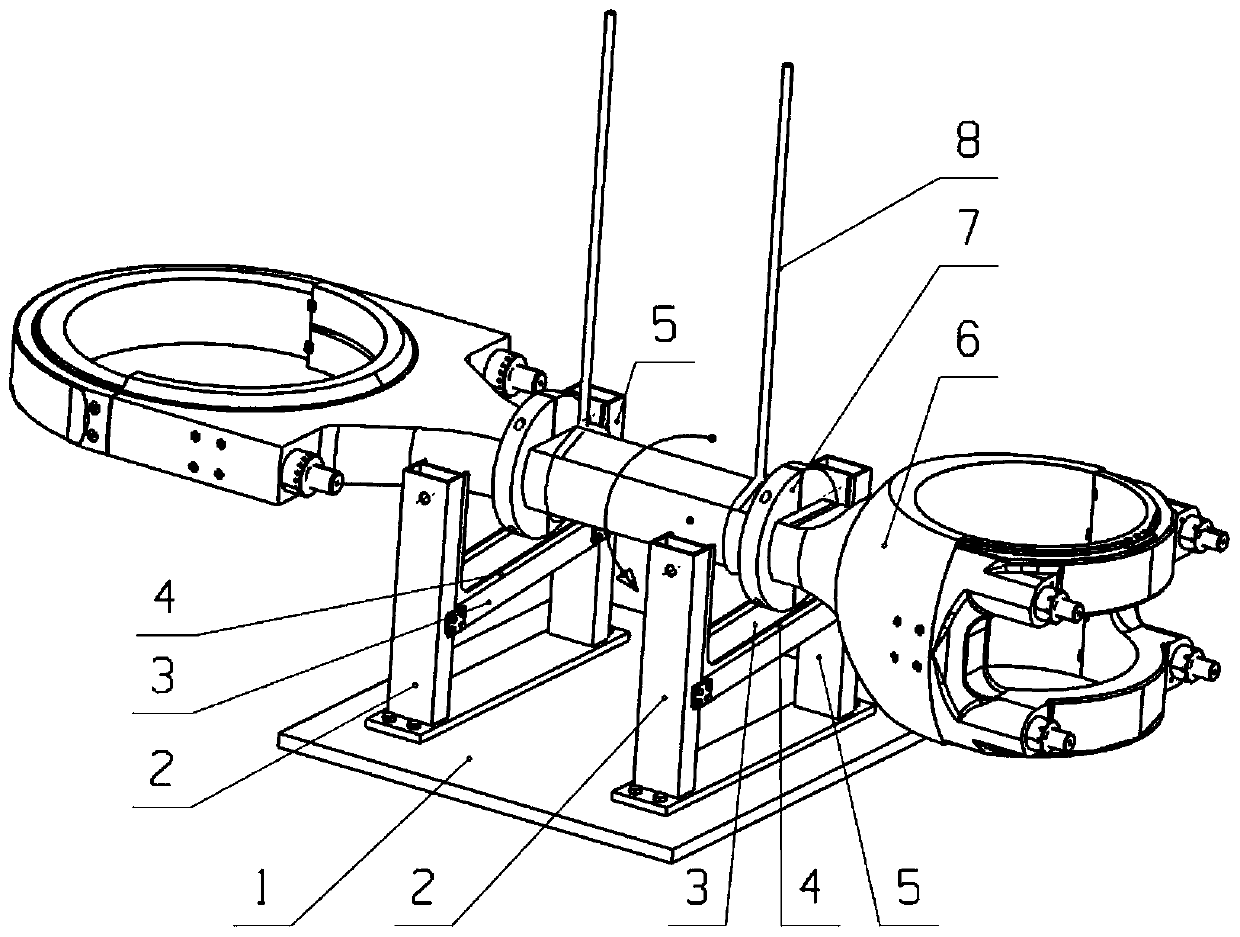

[0036] see figure 1 , the diagram shows that the turning device of the connecting rod of the marine diesel engine based on its own gravity includes a bottom plate 1, two hoop wheels 7 and two brackets.

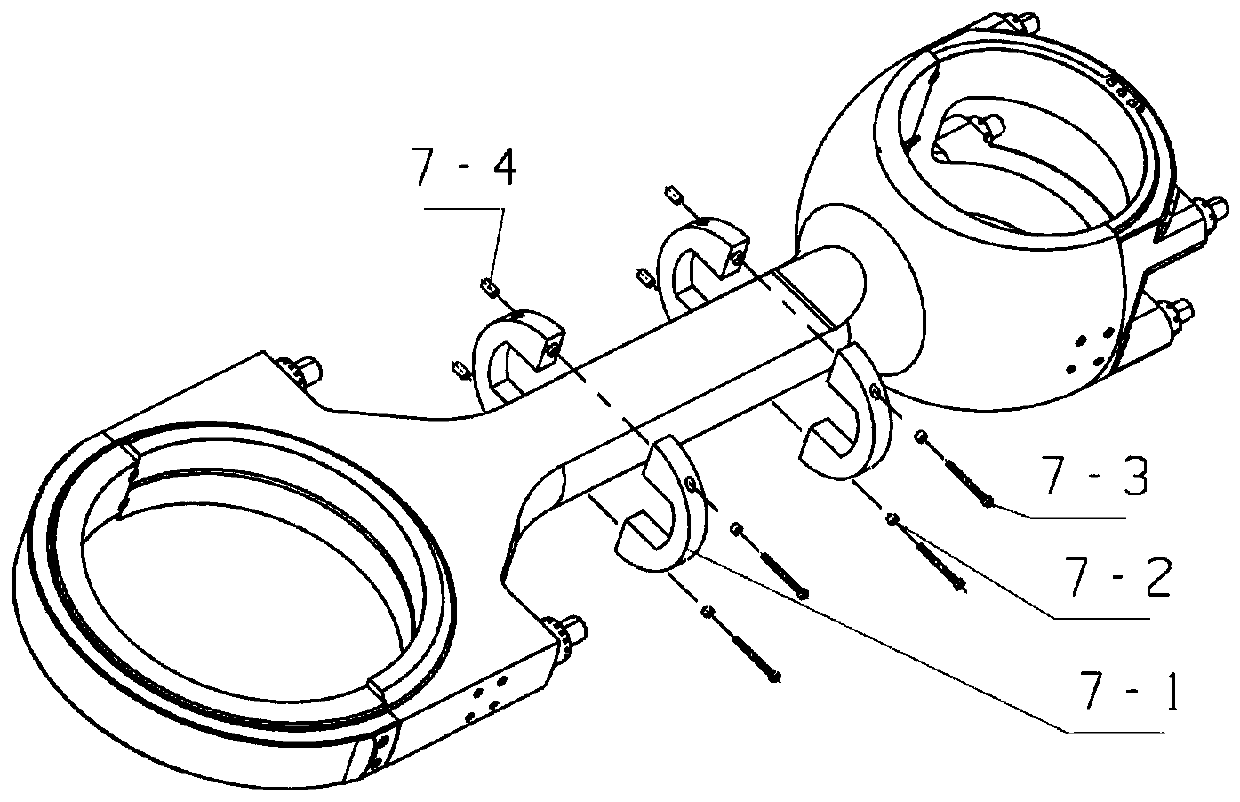

[0037] The inner contour shape of the two hoop wheels 7 is consistent with the shape of the shaft of the connecting rod, and the two hoop wheels 7 are respectively encircled and fixed on the shaft body of the connecting rod close to the big end of the connecting rod and the two sides of the small head, the connecting rod is by its own gravity, with the two hoop wheels 7 rolling on the support from a high place to a low place by itself, thereby realizing a 180° automatic turning over.

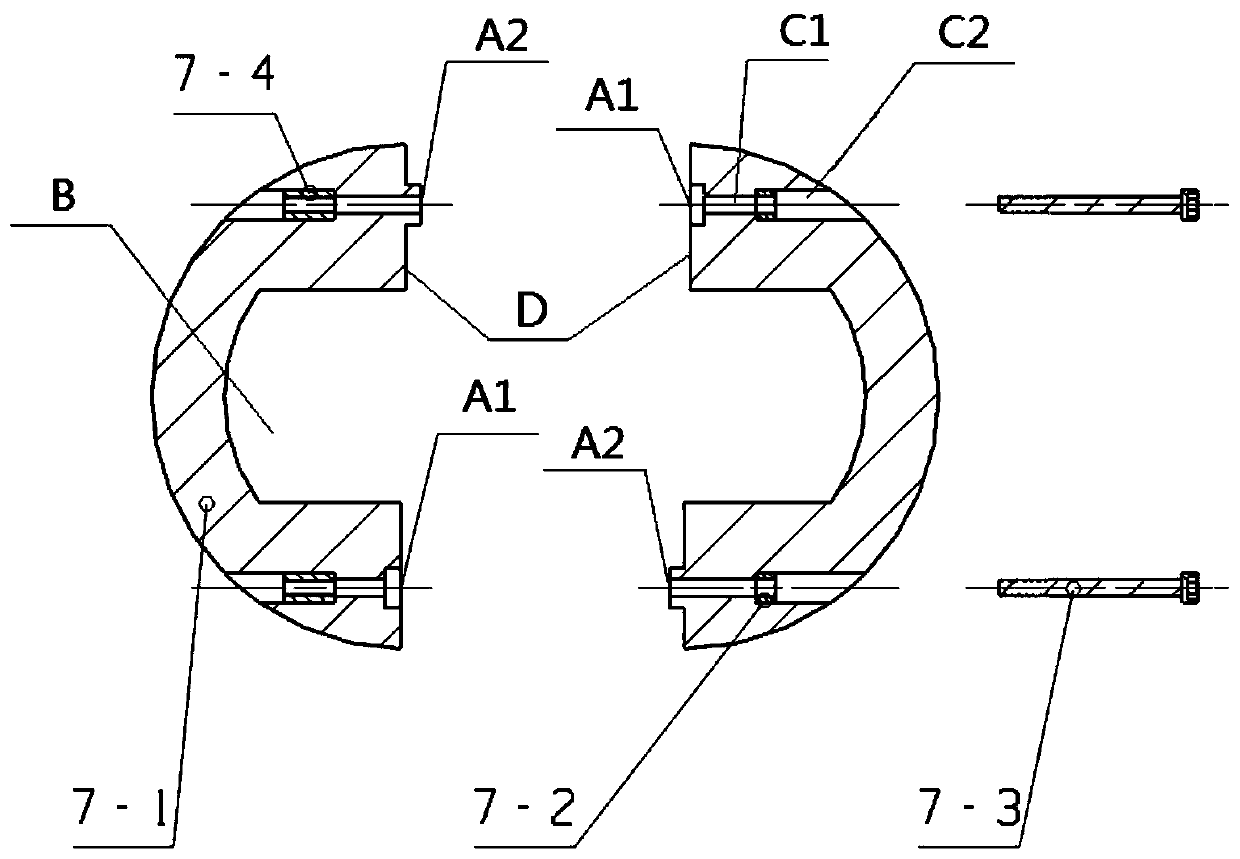

[0038] see figure 2 , the shape of the hoop wheel 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com