Automatic slag remover of aluminum ingots

A technology for automatic slag removal and aluminum ingot removal. It is used in mechanical cleaning, manufacturing tools, metal processing equipment, etc. It can solve the problems of not equipped with slag remover and burn staff, so as to maintain clean and hygienic working environment and reduce labor intensity. , The effect of high slag scraping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

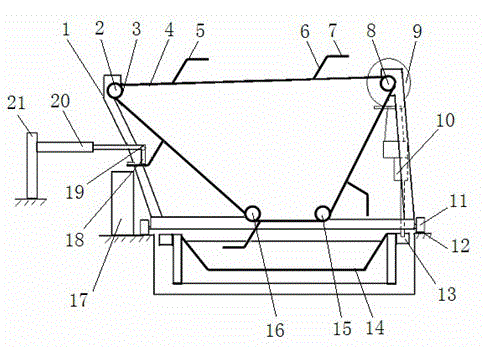

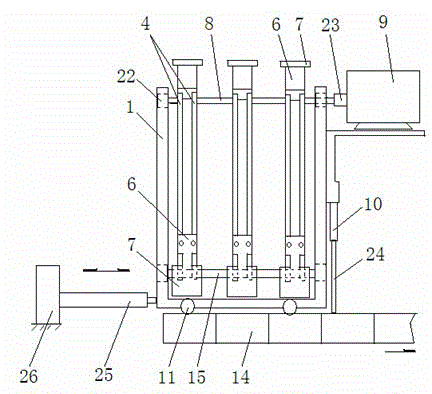

[0018] The aluminum ingot automatic deslagging machine provided by the present invention comprises a frame 1, and the frame 1 is provided with four rotating shafts 2, 8, 15, 16 with sprockets 3 thereon, wherein: the rotating shafts 2, 8 pass through the two ends of the rotating shafts. Bearing and bearing seat 22 are respectively fixed on the left and right sides of the top of frame 1, and one end of rotating shaft 8 links to each other with motor 9 output shaft 23, and rotating shaft 15,16 is respectively fixed on frame by bearing and bearing seat 22 at its two ends. On the left and right sides of the bottom of 1, each of the four rotating shafts of 2, 8, 15, and 16 is provided with six sprockets 3, and is connected with six chains 4 respectively, and every two sprockets 3 and Corresponding two chains 4 form a group, a total of three groups, and a plurality of scraper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com