Switching trolley for mold for core making machine

A core-making machine and mold technology, applied in the direction of manufacturing tools, molding machine parts, casting and molding equipment, etc., can solve problems such as unsafe, difficult operations, and damage to equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

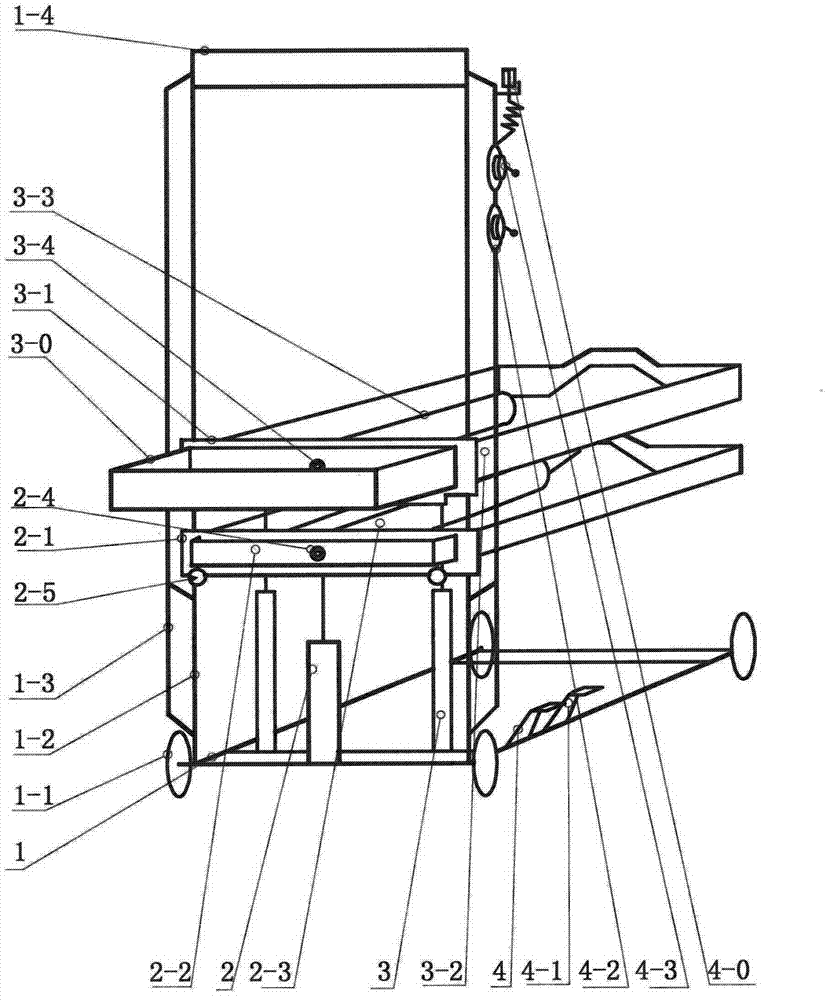

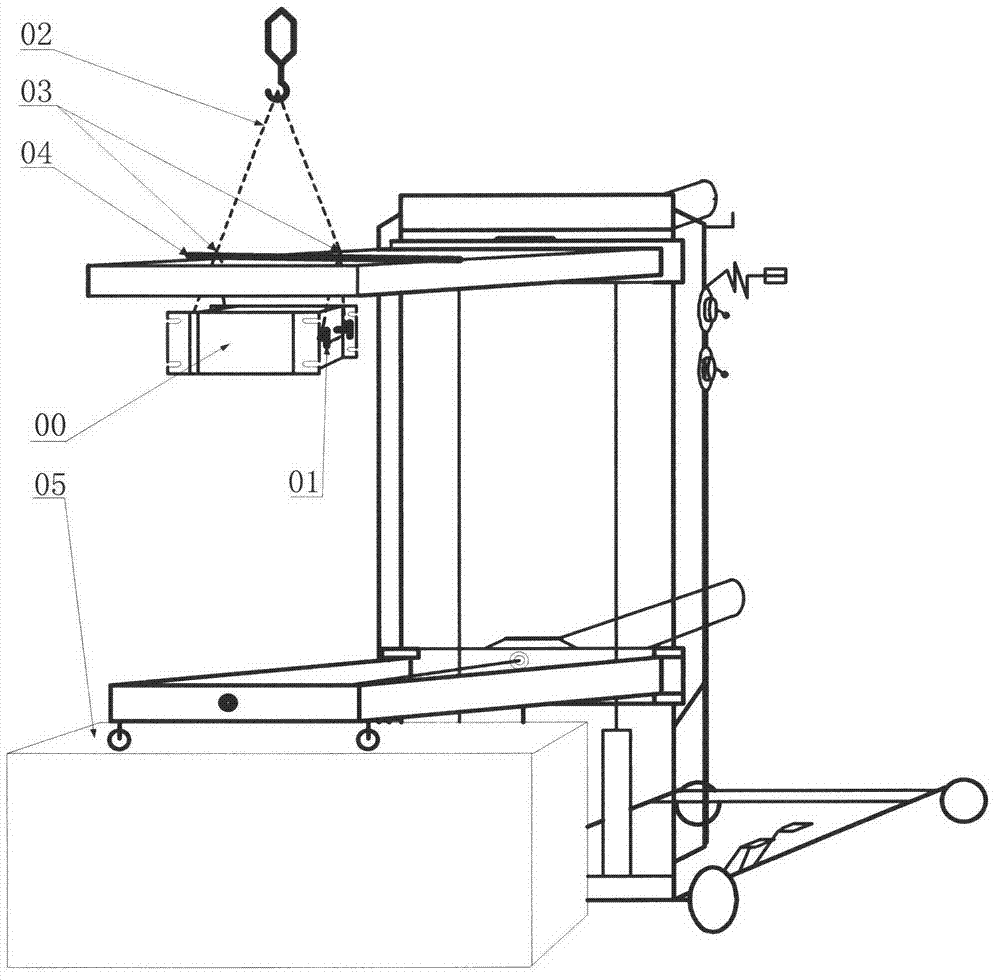

[0009] Attached below figure 1 The specific implementation manner in the present invention will be further described.

[0010] figure 1 , figure 2 Including underframe 1, wheel with brake 1-1, vertical guide rail 1-2, stand 1-3, beam 1-4, extension hydraulic cylinder 2, extension lifting frame 2-1, extension frame 2 -2, stretch cylinder 2-3, stretch frame hole 2-4, stretch wheel 2-5, hanger hydraulic cylinder 3, hanger lifting frame 3-1, hanger 3-2, hanger cylinder 3- 3. Hanger cross arm hole 3-4, Hanger frame 3-0, Stretch lift pedal 4, Hanger lift pedal 4-1, Stretch cylinder manual control valve 4-2, Hanger cylinder control valve 4-3, Air connector 4-4, air source connector 4-0, mold 00, mold hanger 01, long hanger 02, short hanger 03, mold hanger 04, core-making frame platform 05, etc.

[0011] Such as figure 1 , figure 2 As shown, the present invention is a mold switching vehicle for a core making machine, including a frame mechanism, an extension mechanism, a mobil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com