Powdered feed flavor and production method thereof

A production method and technology for flavoring agents, which are applied in the fields of feed additives and feed flavoring agents, can solve the problems of increased energy consumption, low production efficiency, etc., and achieve the effects of reducing production costs, saving energy consumption, and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

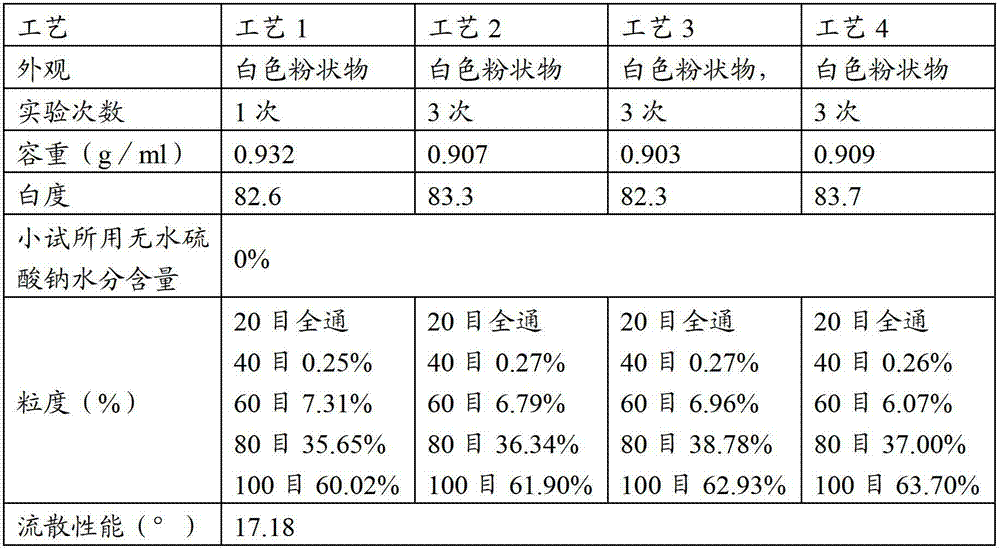

[0025] Liquid fragrance base is made by mixing ethyl lactate, flavor enhancer, diacetyl, dibutyl ester, 3-hydroxy-2-butanone, ethyl butyrate, coconut aldehyde, ethyl dodecanoate and butyl decalactone become. The adsorbent is silicon dioxide and bran, and the filler is anhydrous sodium sulfate, sodium chloride, maltodextrin and stone powder. 150 parts by weight of the liquid fragrance base, 100 parts by weight of the adsorbent, and 800 parts by weight of the filler.

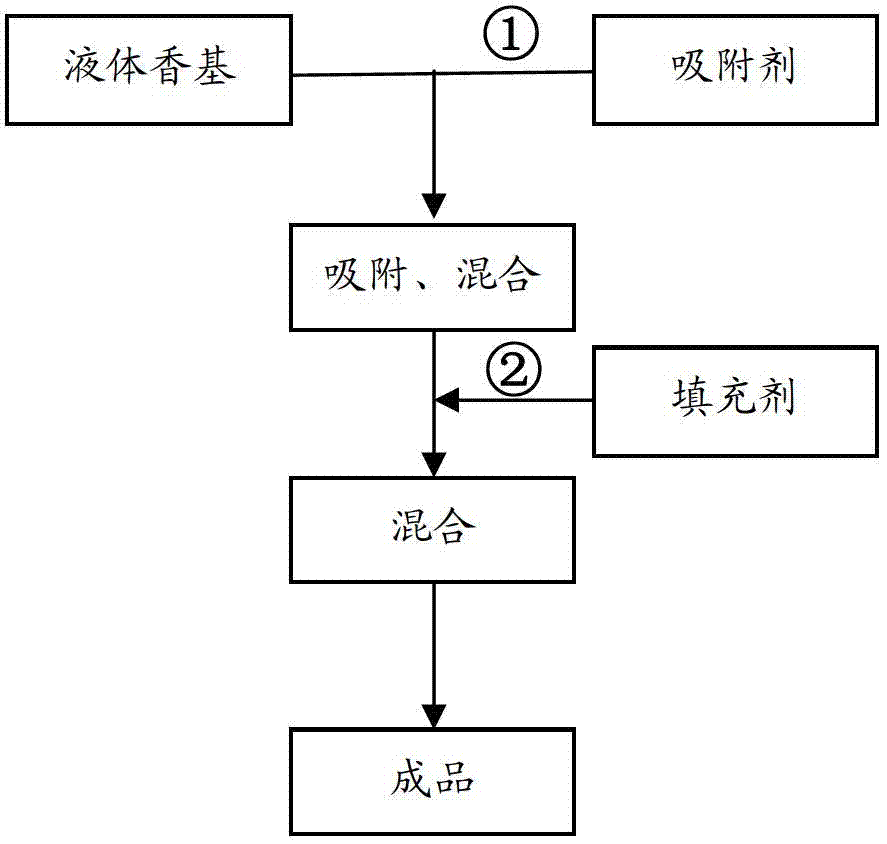

[0026] Process 1 (original process): First, spray the liquid fragrance base evenly on the adsorbent, stir and mix and adsorb for 5 minutes. After the mixing and adsorption are complete, add a certain amount of filler and mix thoroughly for 4 minutes. After the mixing is completed, a fragrance product is made.

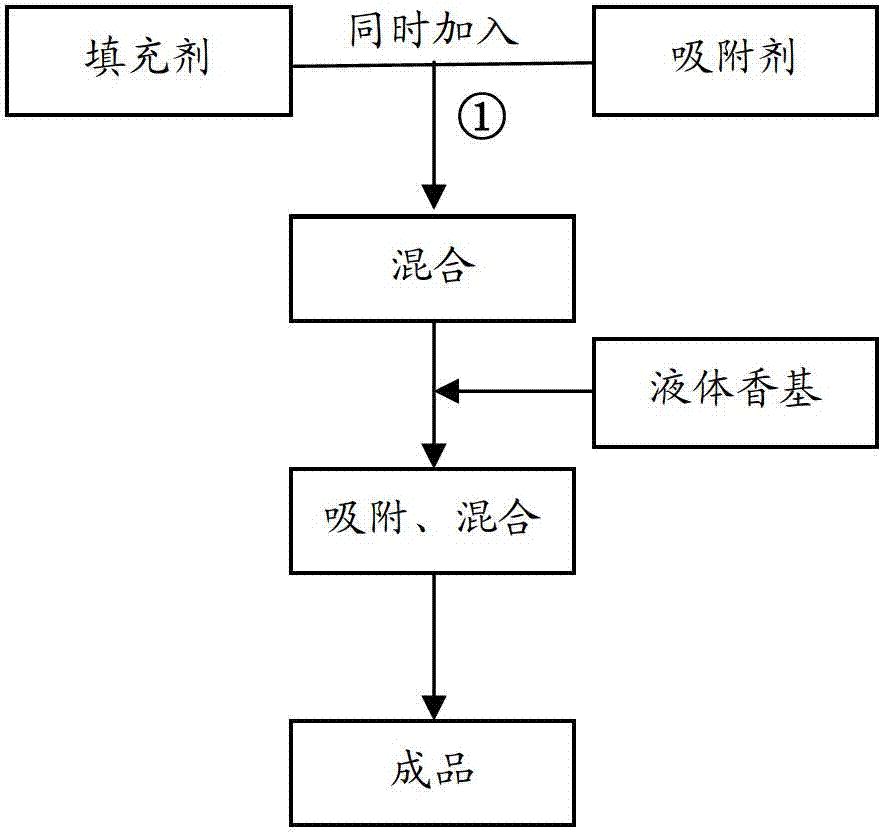

[0027] Process 2: According to the formula, add the adsorbent first, then the filler, and finally add the liquid fragrance base, mix and stir for 5 minutes, and make the fragrance product after the mixing...

Embodiment 2

[0034] Liquid fragrance base is made by mixing ethyl lactate, flavor enhancer, diacetyl, dibutyl ester, 3-hydroxy-2-butanone, ethyl butyrate, coconut aldehyde, ethyl dodecanoate and butyl decalactone become. The adsorbent is silicon dioxide and bran, and the filler is anhydrous sodium sulfate, sodium chloride, maltodextrin and stone powder. 200 parts by weight of the liquid fragrance base, 200 parts by weight of the adsorbent, and 600 parts by weight of the filler.

[0035] Carry out 4 kinds of process preparations according to Example 1, but in process 4, the adsorbent and filler are added at the same time according to the product formula and mixed for 2 minutes. After the mixing is complete, the liquid fragrance base is evenly sprayed in the mixed powder, Stir and mix for 4 minutes, finally make flavor product, obtained result is similar to embodiment 1.

Embodiment 3

[0037] Liquid fragrance base is made by mixing ethyl lactate, flavor enhancer, diacetyl, dibutyl ester, 3-hydroxy-2-butanone, ethyl butyrate, coconut aldehyde, ethyl dodecanoate and butyl decalactone become. The adsorbent is silicon dioxide and bran, and the filler is anhydrous sodium sulfate, sodium chloride, maltodextrin and stone powder. 250 parts by weight of the liquid fragrance base, 300 parts by weight of the adsorbent, and 500 parts by weight of the filler.

[0038] Carry out 4 kinds of process preparations according to Example 1, except that in process 4, the adsorbent and filler are first added at the same time according to the product formula and mixed for 3 minutes. After the mixing is complete, the liquid fragrance base is evenly sprayed in the mixed powder, Stir and mix for 5 minutes, finally make flavoring agent product, obtained result is similar to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com