Farming machine with steel plate machine body and jaw clutch

A tooth-inlay type farming machine technology, which is applied in the field of farming machines, can solve problems such as uneven thickness, easy cracking, and large pollution, and achieve the effects of good clutch effect, easy assembly, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

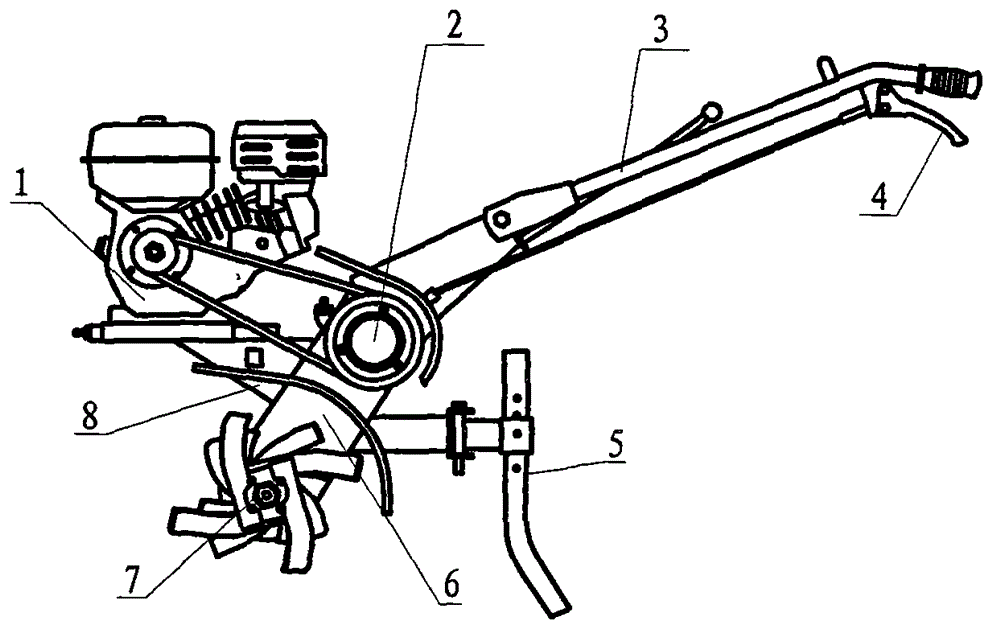

[0018] The preferred embodiment of the present invention is like this, with reference to Figure 1 to Figure 11 As shown, an agricultural machine with a steel plate body with tooth-embedded clutch includes an engine, a movable base, a handrail, a body, a clutch device, and a farming knife, wherein the body 6 is formed by punching and welding steel plates as a whole, and the The clutch active pawl 10 and the separation pawl 11 of the clutch device are connected in a tooth-embedded manner, and the transmission shaft 14 at the upper end of the body 6 is equipped with a clutch spring 12, a separation pawl 11, and a clutch active pawl 10, and the clutch active pawl 10 uses a bolt 9 Connect belt pulley 2, the drive shaft 22 two ends of body 6 lower ends are installed farming knife 7 or rolling field wheel 24. The transmission shaft 14 in the body 6 meshes with the transmission gear 15 of the splined second shaft 16 through the transmission gear 13, and the transmission gear 15 engag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com