Side pump source of vertical-cavity surface-emitting laser and manufacturing method of side pump source

A vertical cavity surface emission and side pumping technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problem that side emitting semiconductor lasers are not suitable for side pumping sources, etc., to improve the input current on-line, beam The effect of quality improvement, increasing the number of light-emitting units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

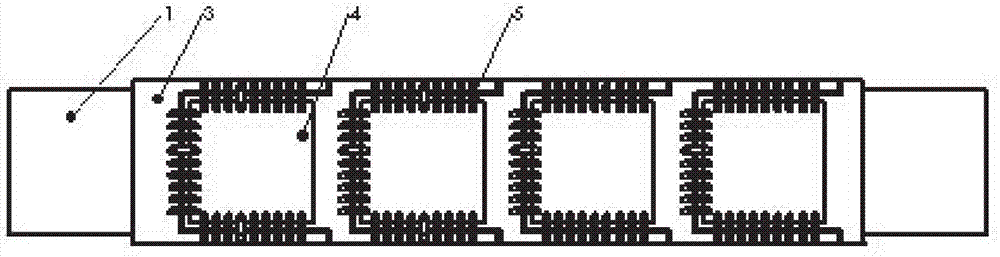

[0038] The inventive idea of the present invention is: to propose a one-dimensional serial connection structure, which can increase the light output unit without significantly increasing the driving current, and can connect gold wires on the three sides of the vertical cavity surface emitting laser to increase the upper limit of the current, and High integration, easy to achieve uniform pumping of the beam, and improve the quality of the output beam.

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings.

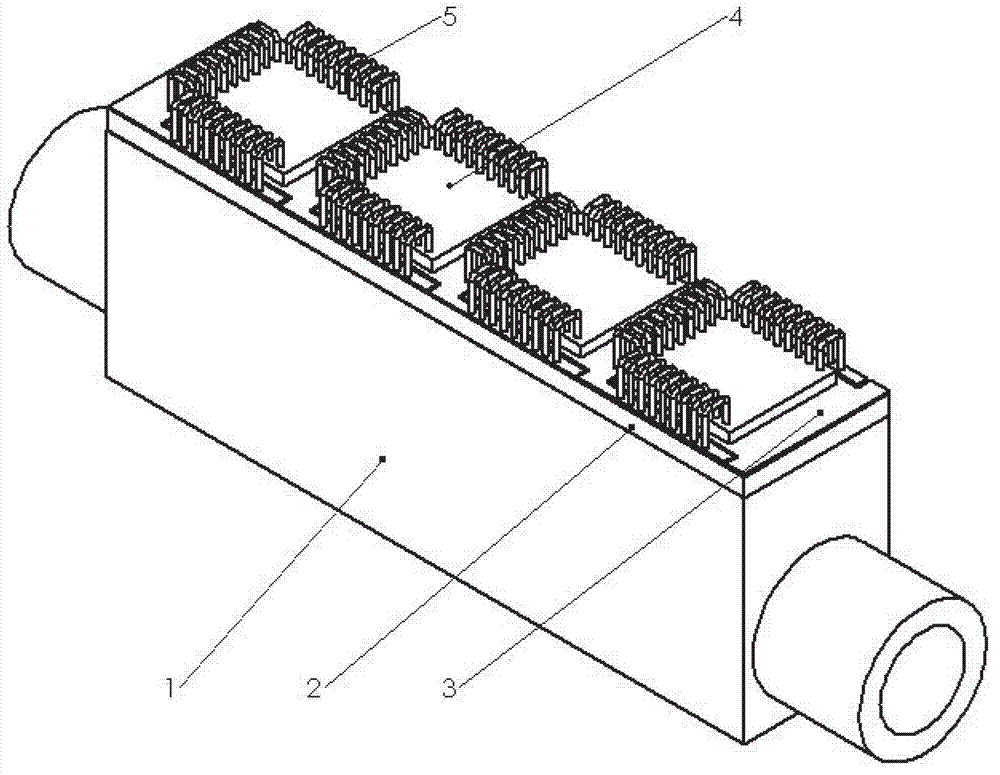

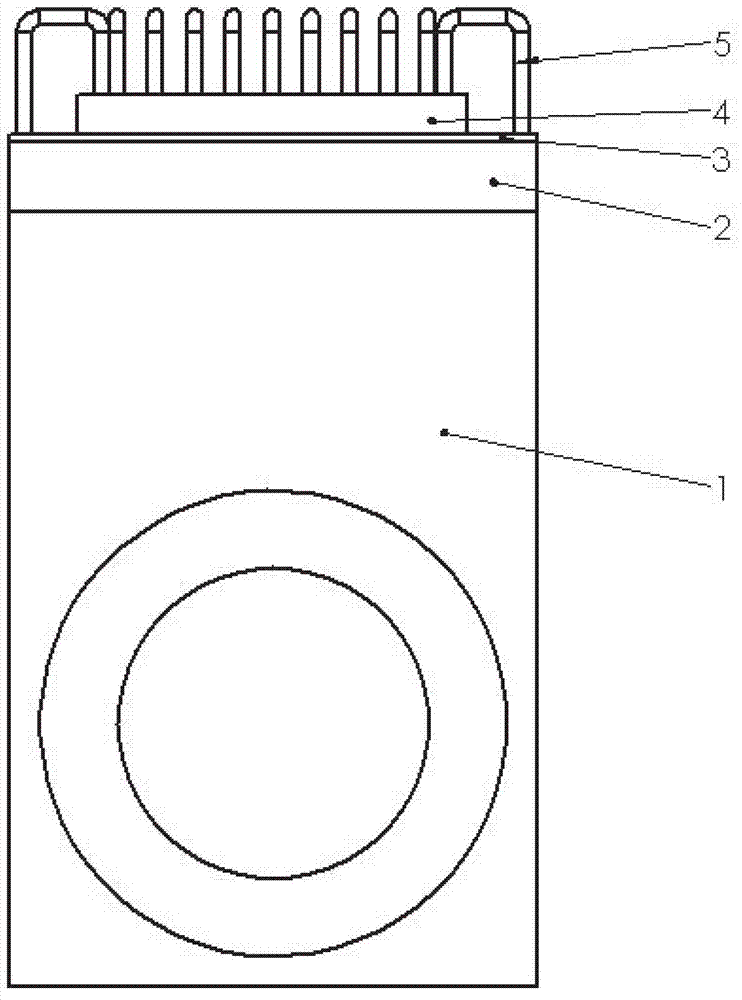

[0040] Such as Figure 1-9 As shown, the vertical cavity surface emitting laser side pump source of the present invention includes: a large channel heat sink 1 with a cooling liquid inside, the upper end of the large channel heat sink 1 is provided with a horizontal mounting surface 6, an insulating heat sink 2, And a vertical cavity surface emitting laser array 4; a metal thin film 3 is plated in the insulating hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com