Wavelength tunable laser with low cost and low power consumption

A laser, low-power technology, applied in the field of wavelength-tunable lasers, can solve the problems of high laser power consumption, non-tunable wavelength, and difficult assembly, and achieve the effects of high optical power, compact structure, and simple assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

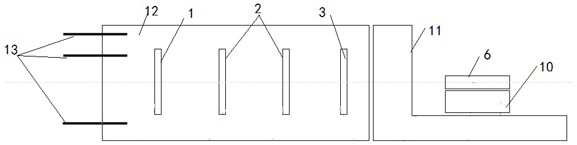

[0018] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

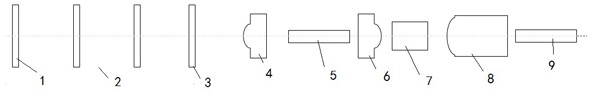

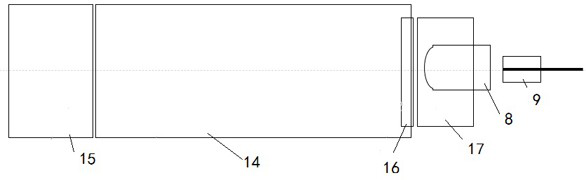

[0019] like Figure 1-3 As shown, a low-cost and low-power tunable wavelength laser includes a mirror 1, an optical etalon 2, a phase controller 3, an aspherical lens A4, a laser chip 5, and an aspherical lens arranged in order from left to right B6, optical isolator 7, convergent lens 8, optical fiber 9;

The laser chip is an SLD chip, and the left and right end faces of the laser chip are respectively coated with an anti-reflection optical film and a partially reflective optical film, and the partially reflective optical film and the reflector on the end face away from the reflector constitute a resonant cavity of the laser;

The aspherical lens A and the aspherical lens B are made of light-transmitting material as the base material, which are used to reshape the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com