Linear array semiconductor laser with photonic crystal structure

A technology of photonic crystals and two-dimensional photonic crystals, which is applied in the direction of semiconductor lasers, lasers, phonon exciters, etc., can solve the problems of difficult preparation process, few light-emitting points, and high series resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

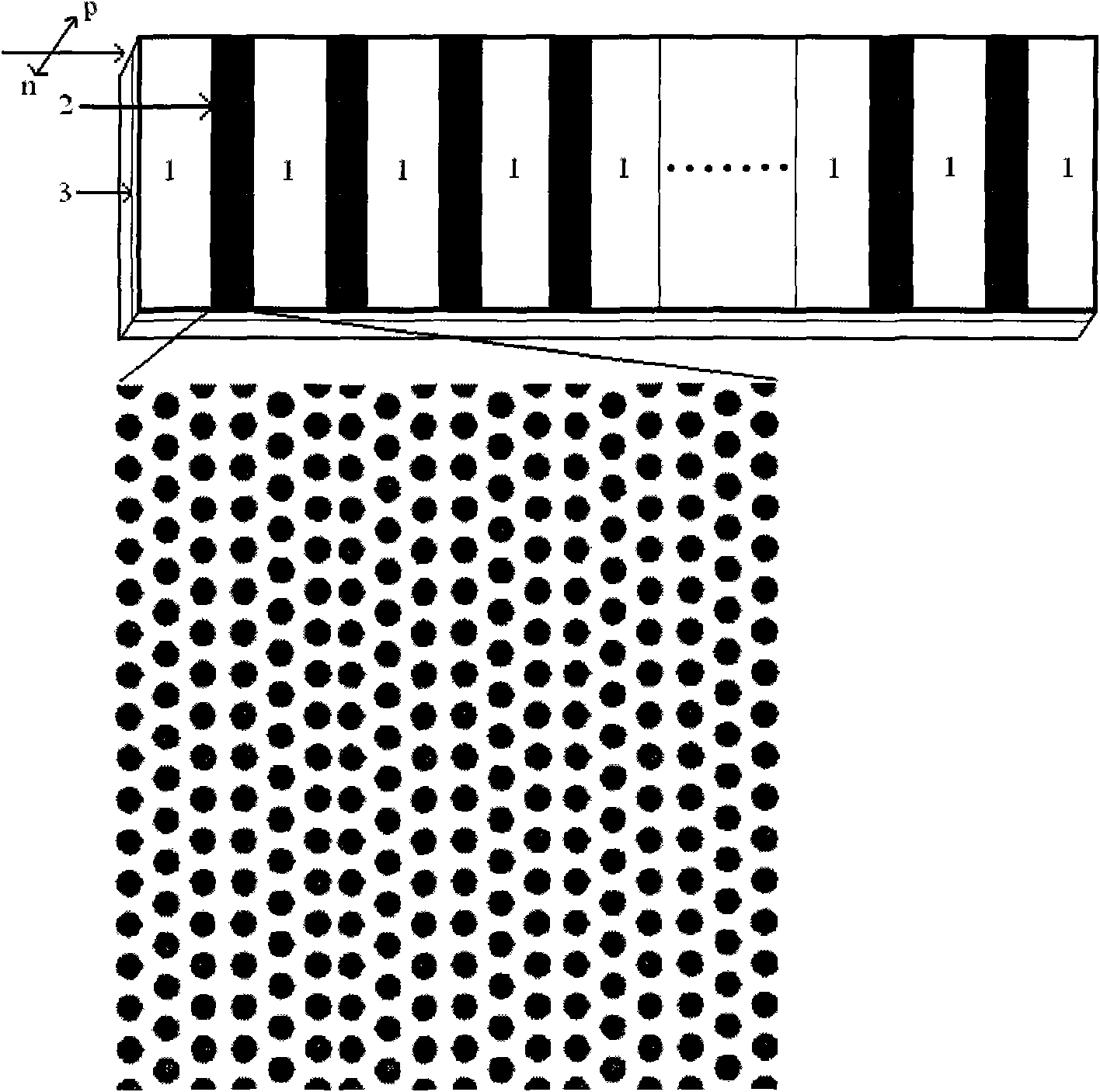

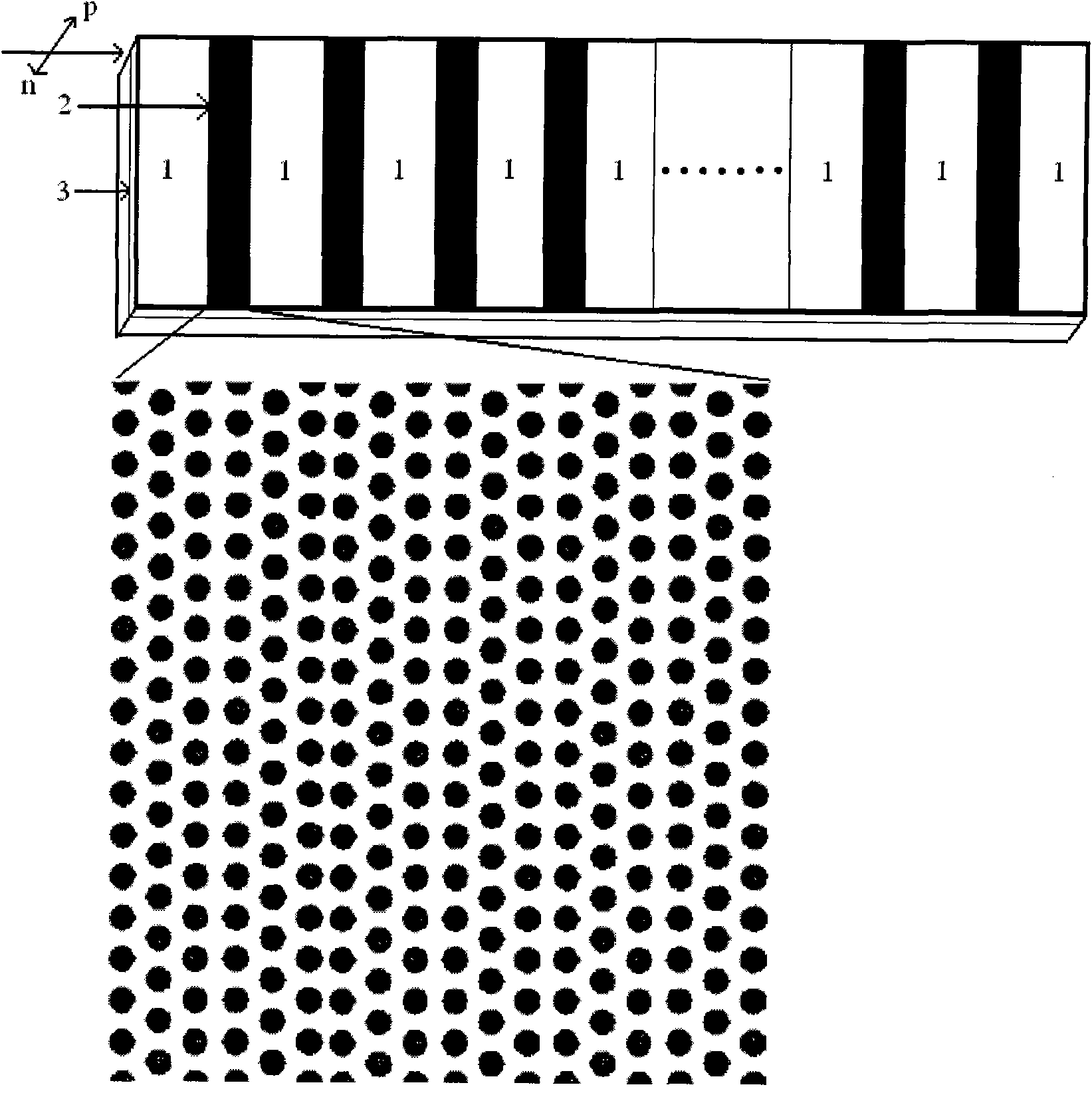

[0015] Specific implementation mode one: see figure 1 As shown, the linear array semiconductor laser structure of photonic crystal structure includes laser epitaxial wafer n-plane structure region, p-plane structure region, active region, two-dimensional photonic crystal distribution region, p-plane current injection region, n-face electrode, p-plane The electrode and the photonic crystal distribution area are composed of an air-hole photonic crystal structure on the semiconductor material, and the photonic crystal structure is used as a mode selection area of a linear array laser and a lateral light isolation area.

specific Embodiment approach 2

[0016] Embodiment 2: The etching depth of holes in the two-dimensional photonic crystal area is 0.8-1.2 microns, and the bottom and side walls of the holes are sequentially attached with titanium, platinum, and gold p-surface electrode materials.

specific Embodiment approach 3

[0017] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the etching depth of the holes in the two-dimensional photonic crystal region is 1.2-5 microns, and the bottom and side walls of the holes are covered with aluminum oxide or aluminum nitride or silicon dioxide. an insulating medium layer, and on the insulating medium layer are titanium, platinum, and gold p-surface electrode materials in sequence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com