Liquid crystal device and manufacture method thereof

A technology of liquid crystal device and manufacturing method, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of high cost, large consumption of material resources, manpower and financial resources, etc., to improve adhesion, reduce production cost, increase humidity area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

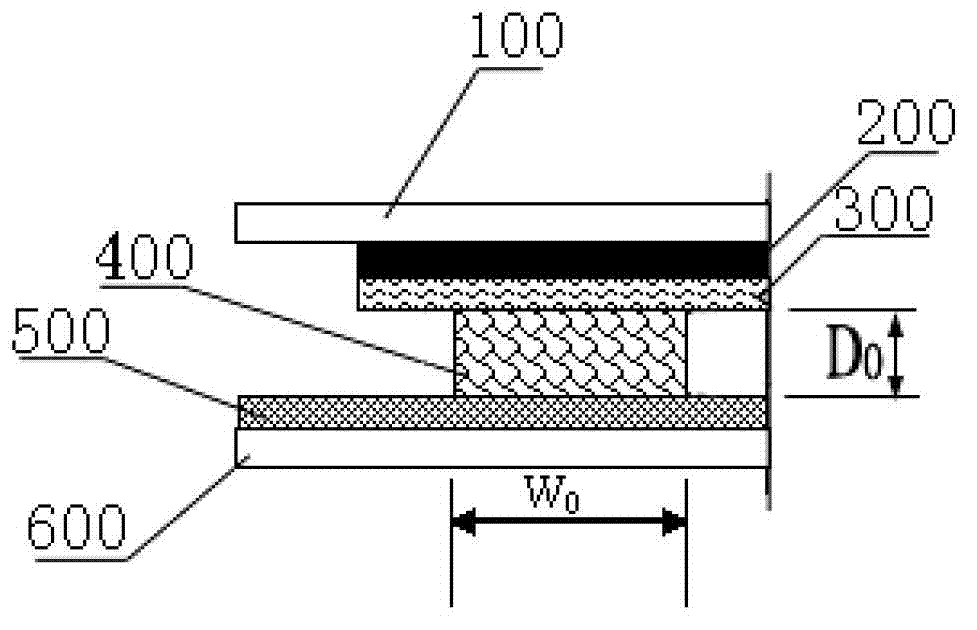

[0046] figure 2 is a schematic structural view of the liquid crystal device described in Embodiment 1 of the present invention, as figure 2 As shown, the liquid crystal device includes: a sealant 400, a protective film OC300, a black matrix layer BM200, and a color filter substrate 100 sequentially located above the sealant 400, and a protective layer PVX500 and Array substrate 600.

[0047] A first through hole is disposed on the protective film OC300 , and the first through hole penetrates through the protective film OC300 . A third groove is disposed on the black matrix layer BM200. The first through hole is arranged correspondingly to the third groove, has the same hole diameter and shape, and is connected as a whole. The upper part of the sealant 400 is located inside the first through hole and the third groove at the same time.

[0048] The protective layer PVX500 is provided with a second groove, and the lower part of the sealant 400 is located inside the second g...

Embodiment 2

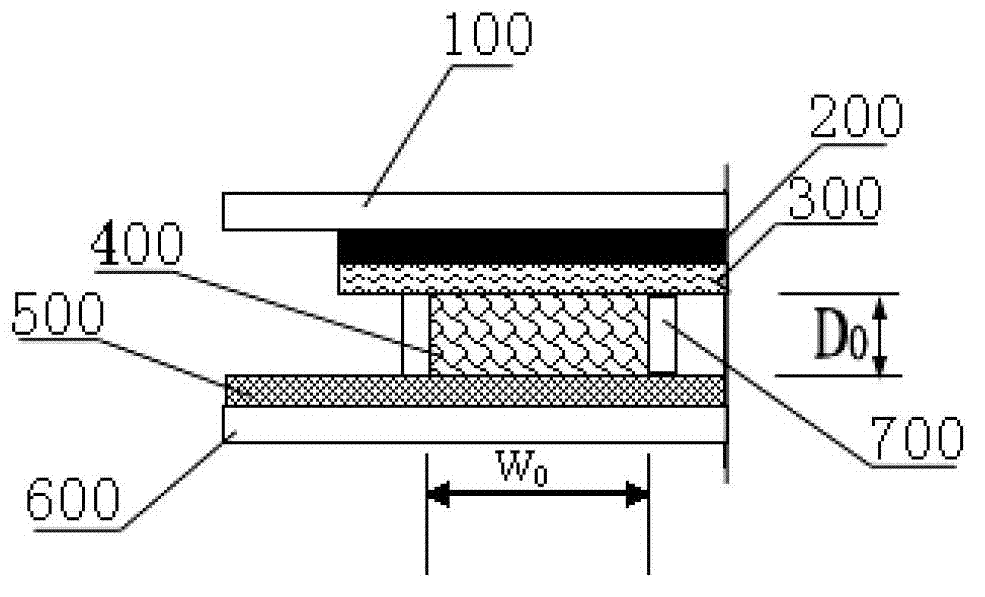

[0051] image 3 It is a structural schematic diagram of the liquid crystal device described in Embodiment 2 of the present invention, such as image 3 As shown, the liquid crystal device described in this embodiment is basically the same as the liquid crystal device described in Embodiment 1. The difference is that in this embodiment, only the first groove is provided on the protective film OC300, but not on the black matrix layer BM200. As for the third groove, the second groove is not provided on the protective layer PVX500. Wherein, the upper part of the sealant 400 is located inside the first groove, and the lower part is bonded to the protective layer PVX500. This design method can also increase the wet area of the sealant 400, and its wet area increase value is W 0 ×d3, therefore, it is also possible to achieve a narrow border while ensuring the bonding effect of the liquid crystal device; at the same time, since the etching process of the black matrix layer BM200 an...

Embodiment 3

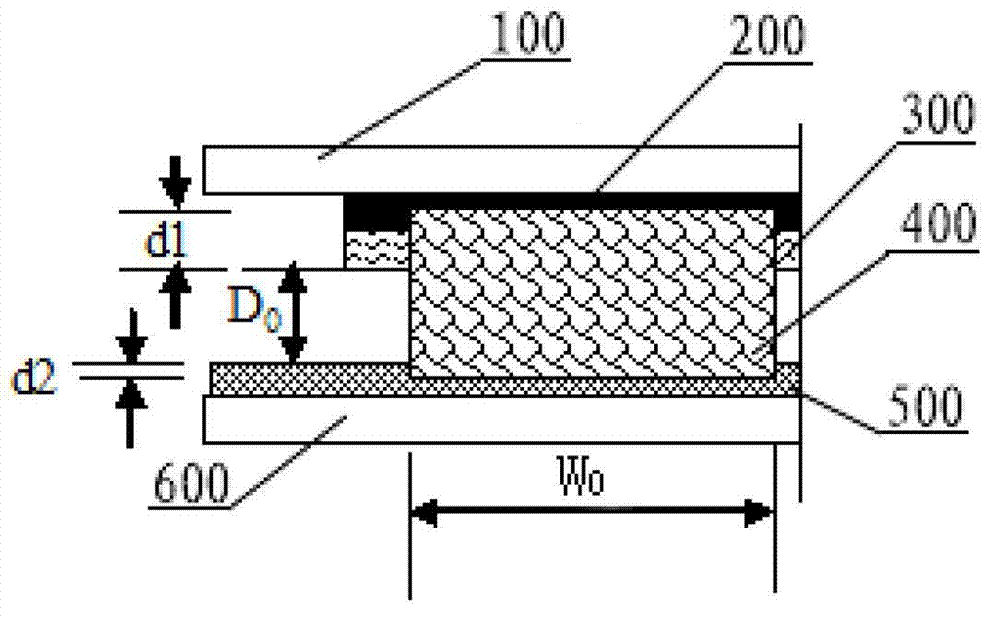

[0054] Figure 4 is a schematic structural view of the liquid crystal device described in Embodiment 3 of the present invention, as Figure 4 As shown, similar to Embodiment 2, the liquid crystal device described in this embodiment only has the second groove set on the protective layer PVX500, but does not set the third groove on the black matrix layer BM200, nor does it set the third groove on the protective film OC300. A slot or first through hole. This design method can also increase the wet area of the sealant 400, and its wet area increase value is W 0 ×d4, therefore, a narrow frame can also be realized while ensuring the bonding effect of the liquid crystal device.

[0055] Wherein, when there is a via hole on the array substrate 600 , the depth d4 of the second groove cannot reach or exceed the thickness of the protection layer PVX500 , so as to prevent the electrodes on the array substrate 600 from being exposed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com