Automobile brake controlled by wire

An automotive wire and brake technology, applied in the direction of brake type, axial brake, brake actuator, etc., can solve the problem of lack of brake clearance adjustment function, large axial and radial dimensions, slow braking response speed, etc. problem, to achieve the effect of simple structure, low energy consumption and good braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

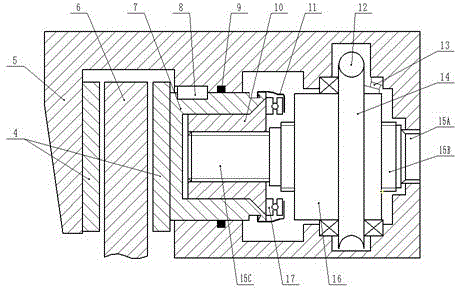

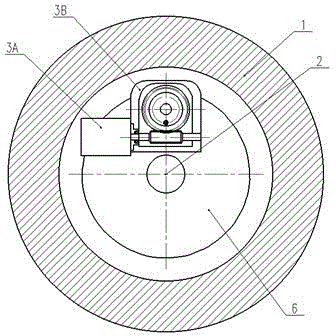

[0037] like figure 1 As shown, the automobile brake-by-wire 3B of the present invention includes a brake disc 6, and friction plates 4 are arranged on both sides of the brake disc 6, and the friction plates 4 are fixedly connected to the piston 7; The radial connection of 5 prevents the piston 7 from rotating, and a sealing ring 9 is arranged between the piston 7 and the brake caliper body 5; the piston 7 can move along the axial direction of the brake caliper body 5;

[0038] The piston 7 is connected to the trapezoidal nut 10, and the trapezoidal nut 10 can move axially along the inner hole of the piston 7; the cooperation between the piston 7 and the trapezoidal nut 10 can be realized through a tapered surface, which can prevent the gap between the piston 7 and the trapezoidal nut 10 in the braking stage. relative rotation of

[0039] The trapezoidal nut 10 is connected with the trapezoidal thread end 15C of the lead screw; the left end of the lead screw is the trapezoidal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com