Composite pile foundation

A composite pile foundation and single pile foundation technology, applied in the field of foundation structure and pile foundation, can solve the problems of single pile foundation diameter, wall thickness, penetration depth increase, complex structure and construction technology, and difficulties in offshore piling construction, etc., to achieve Improved vertical load and moment capacity, material cost reduction, and reduced pile length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

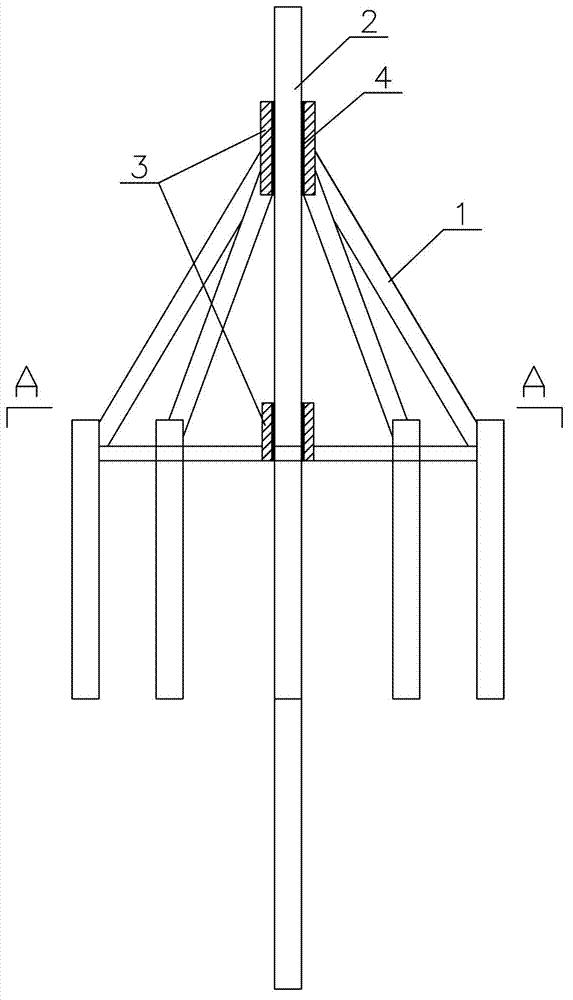

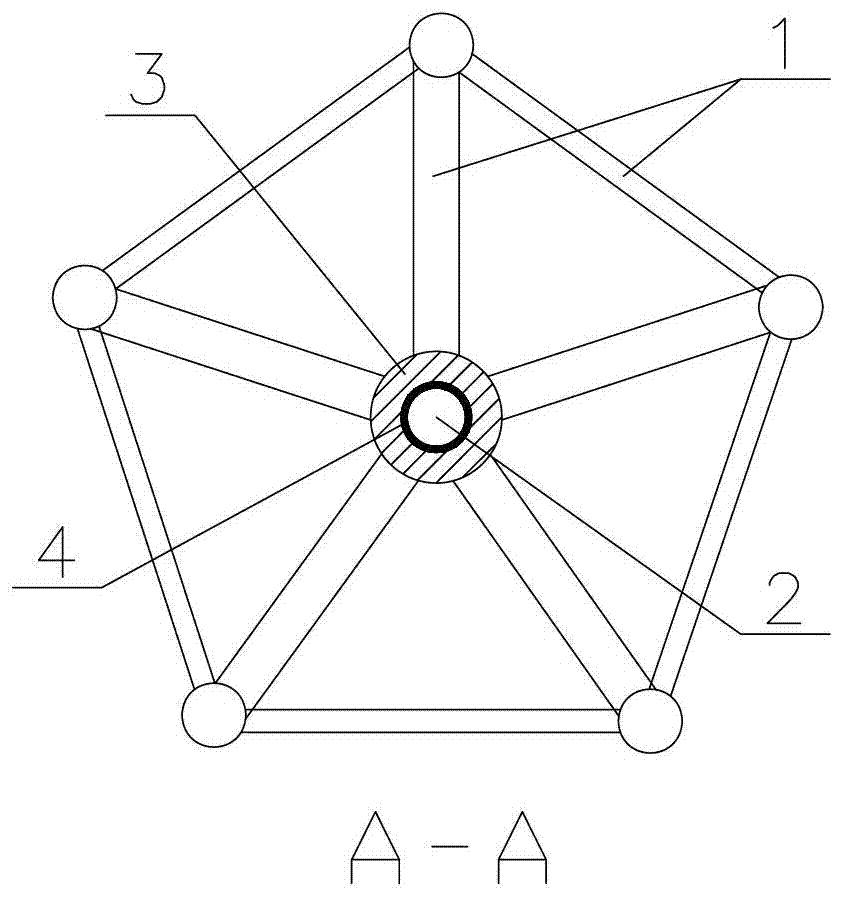

[0020] Such as figure 1 and figure 2 As shown, this embodiment discloses a composite pile foundation, which mainly includes a five-legged support foundation 1 , a single pile foundation 2 and a connecting section 3 .

[0021] The five-leg support foundation 1 includes a truss and five piles. The weight of the truss is 350t; the diameter of the pile is 1.5m, the wall thickness is 20mm, the length is 15m, and the distance between the five piles is 30m.

[0022] The monopile foundation 2 is a steel cylinder structure with a diameter of 3m, a wall thickness of 30mm, and a length of 30m.

[0023] The connecting section 3 is two steel cylindrical structures with an outer diameter of 3.2m and a height of 1.5m, which are respectively fixed on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com