Electromagnetic radiation shielding fiber, and its manufacturing method

An electromagnetic radiation shielding and electromagnetic radiation technology, applied in the direction of single-component polyester rayon, single-component polyamide rayon, etc., can solve the difficulties of spinning high-count yarn, high relative density, large friction coefficient, etc. problems, to achieve the effect of strong durability, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

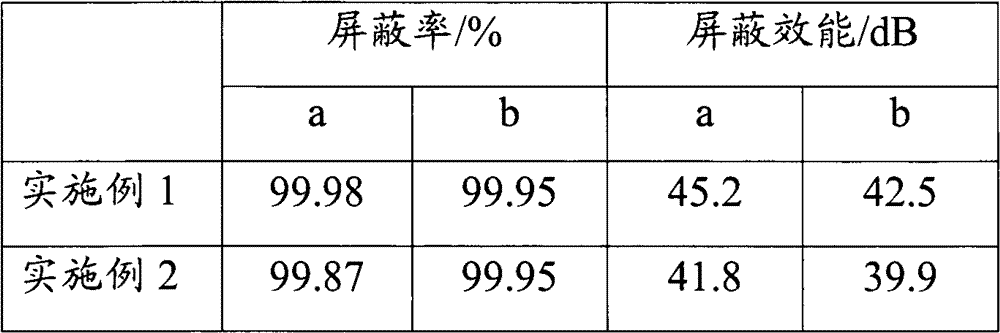

Examples

Embodiment 1

[0026] Electromagnetic radiation absorbing nanopowder preparation:

[0027] Nano iron oxide 40g,

[0028] Nano silicon dioxide 20g,

[0029] 5 grams of nano-iron powder;

[0030] The above ingredients are mixed.

[0031] Preparation of electromagnetic radiation absorbing nano powder masterbatch:

[0032] Blend and dry the electromagnetic radiation absorbing nanometer powder and fiber base material, add polymer spinning aid, enter the screw extruder to melt, blend and extrude, and granulate to obtain electromagnetic radiation absorbing nanometer powder masterbatch; fiber base material and electromagnetic The weight ratio of the radiation-absorbing nanopowder ultrafine powder is 100:5.

[0033] Electromagnetic radiation shielding fiber production:

[0034] After blending the electromagnetic radiation absorbing nano-powder masterbatch and fiber chips, the electromagnetic radiation shielding fiber is formed after spinning, winding and stretching. The masterbatch and fiber sl...

Embodiment 2

[0036] Electromagnetic radiation absorbing nanopowder preparation:

[0037] Nano iron oxide 50g,

[0038] Nano silicon dioxide 35g,

[0039] 8 grams of nano-iron powder;

[0040] The above ingredients are mixed.

[0041] Preparation of electromagnetic radiation absorbing nano powder masterbatch:

[0042] Blend and dry the electromagnetic radiation absorbing nanometer powder and fiber base material, add polymer spinning aid, enter the screw extruder to melt, blend and extrude, and granulate to obtain electromagnetic radiation absorbing nanometer powder masterbatch; fiber base material and electromagnetic The weight ratio of the radiation absorbing ultrafine powder is 100:15.

[0043] Electromagnetic radiation shielding fiber production:

[0044] After blending the electromagnetic radiation absorbing nano-powder masterbatch and fiber chips, the electromagnetic radiation shielding fiber is formed after spinning, winding and stretching. The masterbatch and fiber slices are m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com