Actinobacillus succinate producing strain and method for its screening and fermentative production of succinic acid

An actinomycetes, succinic acid-producing technology, applied in the field of bioengineering, can solve the problems of unreachable yield, difficult to obtain strains, low yield and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

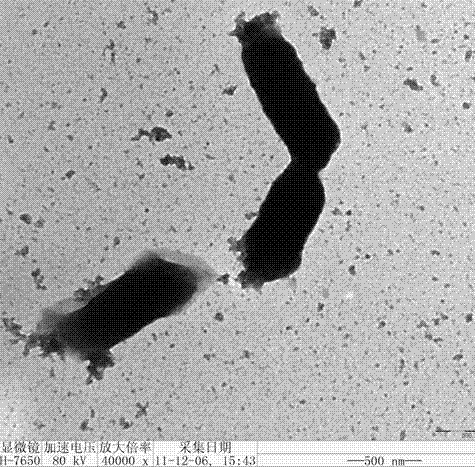

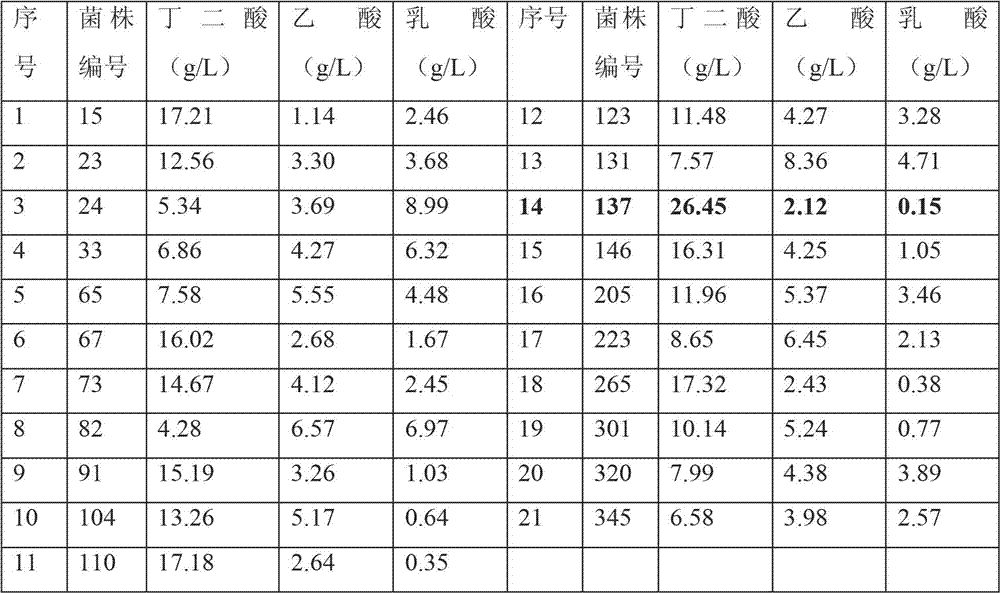

[0058] Screening and identification of strains of Actinobacillus succinate:

[0059] 1. Preparation of enrichment medium: a medium containing fumarate as the sole carbon source and adding nitrogen sources, inorganic salts and monensin. The detailed formula is as follows (g / L): sodium fumarate 10-30, yeast powder 5-20, peptone 5-20, K 2 HPO 4 1-5, CaCl 2 0.1-1, NaCl 0.5-2, (NH 4 ) 2 SO 4 0.5-2, MgCl 2 0.1-1, monensin 0.1-0.2, mix the aforementioned raw materials to obtain an enriched medium. It is verified by experiments that the enrichment medium prepared by any combination of concentrations in the aforementioned enrichment medium raw material formula can screen the GXAS-137 strain of the present invention.

[0060] 2. Preparation of plate screening medium: Add sodium succinate and agar powder on the basis of enriched medium. The detailed formula is as follows (g / L): sodium fumarate 10-30, yeast powder 5-20, peptone 5-20, K 2 HPO 4 1-5, CaCl 2 0.1-1, NaCl0.5-2, (NH 4 ) 2 SO 4 0.5-...

Embodiment 2

[0110] According to the method of fermentative production of succinic acid by Actinobacillus succinate-producing strain in Example 1, the plate of the strain with the deposit number CCTCCNO:M2011399 was cultured in an anaerobic box for 48 hours, and then a loop was connected to 30mL seed culture medium with an inoculation loop. Cultivate for 20 hours at 37°C, and access fermentation medium (250 mL Erlenmeyer flask with a liquid volume of 150 mL) of different carbon sources (65 g / L based on glucose) according to the 5% inoculum volume, and statically culture for 48 hours. The content of diacid and main by-products, the results are shown in Table 2.

[0111] Table 2 Effects of different carbon sources on the production of succinic acid by CCTCC NO: M2011399

[0112] Carbon source Succinic acid content (g / L) Acetic acid content (g / L) Lactic acid content (g / L) glucose47.9810.681.63 sucrose50.318.360.91 fructose40.349.271.39 maltose49.6710.831.50 Arabic candy54.767.241.37 Xyl...

Embodiment 3

[0115] According to the method for fermentative production of succinic acid by the strain of Actinobacillus succinate in Example 1, the plate of the strain with the deposit number CCTCCNO: M2011399 was cultured in an anaerobic box for 48 hours, and then a loop was connected to 30 mL of seed medium with an inoculum loop, 37 Cultivate for 20h at ℃, insert fermentation medium (250mL Erlenmeyer flask with a liquid volume of 150mL) of different raw materials (75g / L based on glucose) according to the 5% inoculum, static culture for 48h, and determine succinic acid by HPLC And the main by-product content, the results are shown in Table 3.

[0116] Table 3 Effects of different raw materials on the production of succinic acid by CCTCC NO: M2011399

[0117] Carbon source Succinic acid content (g / L) Acetic acid content (g / L) Lactic acid content (g / L) Tapioca flour70.1710.771.46 corn flour53.8112.342.01 Cane molasses49.377.261.17 Sugar cane juice58.678.911.64

[0118] It can be seen fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com