Crosslinked polyethylene composition and application thereof

A technology of cross-linked polyethylene and its composition, which is applied in the field of polyethylene foaming, can solve the problems of high airtightness of mattresses and the inability to continue to use them, and achieve the effects of less heat loss, small gaps, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

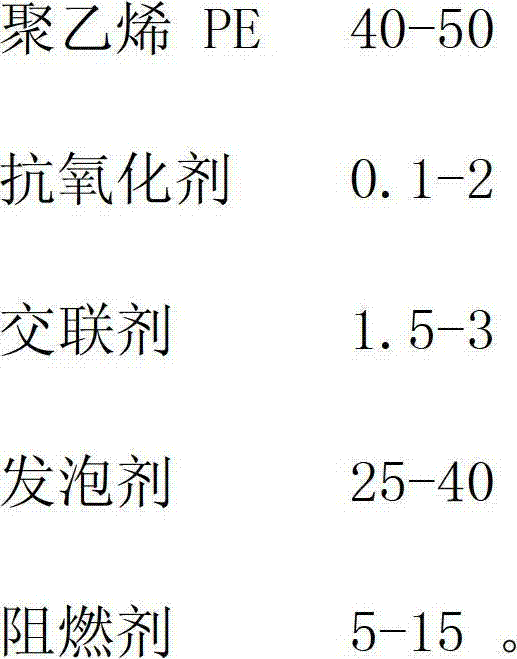

[0035] Cross-linked polyethylene composition 1, the composition formula includes:

[0036]

[0037] preparation:

[0038] Using foaming equipment, add the above-mentioned components one by one according to the conventional steps to obtain cross-linked polyethylene composition 1.

[0039] The cross-linked polyethylene composition 1 prepared above is used to prepare an insulation pad, and the specific structure is as follows:

[0040] From top to bottom, there are sandwich mesh cloth layer, spray cotton layer, cross-linked polyethylene composition layer and T / C cloth layer.

[0041] Quilt the above-mentioned insulation pad; quilt into parallel rosettes.

[0042] Cutting: Cut into pieces according to the size of the product, which can be cut with manual scissors, or use a mold to punch the pieces with a punch; the edge is ready.

Embodiment 2

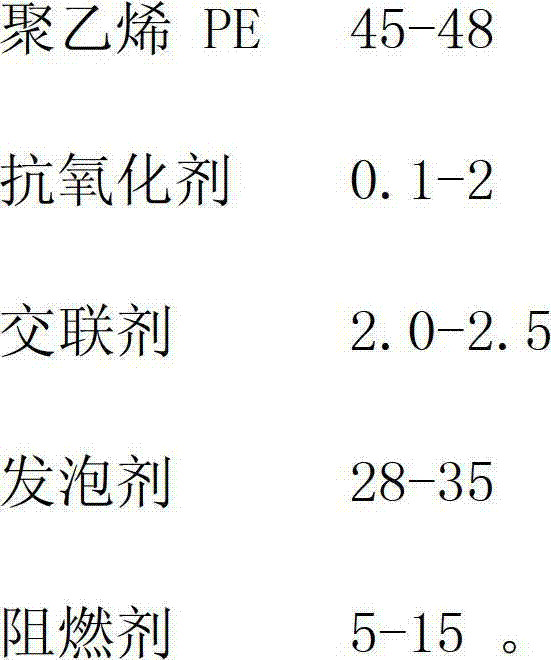

[0044] Cross-linked polyethylene composition 2, the composition formula includes:

[0045]

[0046]

[0047] The preparation is the same as in Example 1, except that when adding polyurethane, pay attention to the uniformity of dispersion.

[0048] The cross-linked polyethylene composition 2 prepared above is used to prepare an insulation pad, and the specific structure is as follows:

[0049] From top to bottom, there are the polar fleece layer, spray cotton layer, cross-linked polyethylene composition layer and chemical fiber cloth layer.

[0050] Quilt the above-mentioned insulation pad; quilt into a square shape.

[0051] Cutting: Cut into pieces according to the size of the product, which can be cut with manual scissors, or use a mold to punch the pieces with a punch; the edge is ready.

Embodiment 3

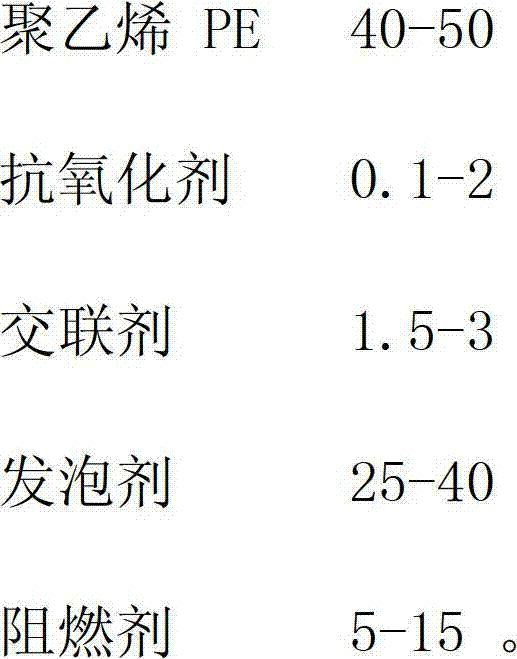

[0053] The formulas of cross-linked polyethylene compositions 3 and 4 are as follows:

[0054]

[0055] The preparation is the same as in Example 2.

[0056] The above-prepared cross-linked polyethylene composition 3 or 4 is used to prepare an insulation pad, and the specific structure is as follows:

[0057] From top to bottom, they are towel cloth, cross-linked polyethylene composition layer and pure cotton cloth.

[0058] Quilt the above insulation pad; it can be quilted into a wave shape.

[0059] Cutting: Cut into pieces according to the size of the product, which can be cut with manual scissors, or use a mold to punch the pieces with a punch; the edge is ready.

[0060] The cross-linked polyethylene composition prepared above has a fine independent bubble structure, which can effectively reduce the energy exchange caused by air convection, is non-toxic, tasteless, easy to process, can be cut at will, and fits a variety of materials. This is a highly efficient, energy-saving and en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com