The synthetic method of methoxycephalosporin intermediate 7-mac

A synthetic method, the technology of metoxycephalosporin, which is applied in the field of cephalosporin drug intermediates, can solve the problems of high price and difficulty in realizing industrial production, and achieve the effects of simple operation, easy industrial production, and recyclable solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

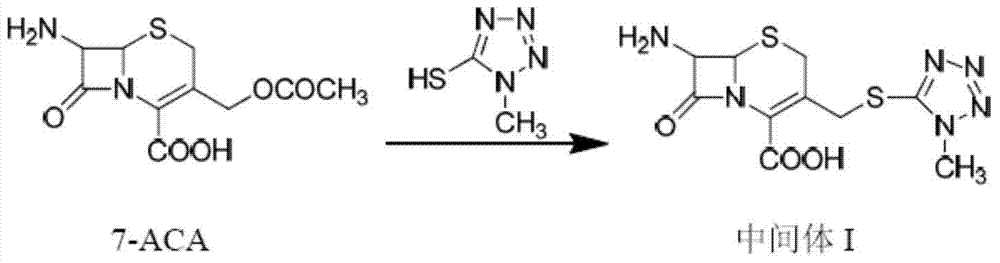

[0045] A kind of synthetic method of metoxyceph intermediate 7-MAC, it is characterized in that comprising the following steps:

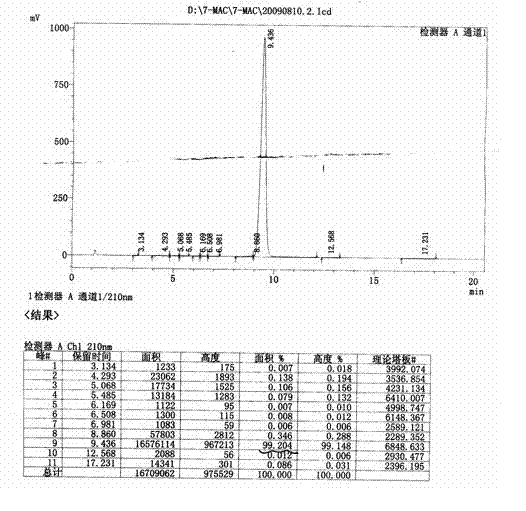

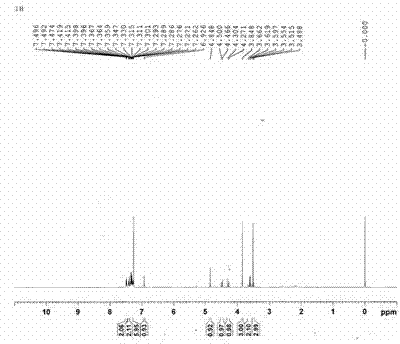

[0046]1. Synthesis of intermediate I: Add 1000mL of acetonitrile into the reaction bottle, cool to -15~-20°C, slowly add 200mL of concentrated sulfuric acid dropwise, add 128g (1.10mol) of methylmercaptotetrazolium, stir for 20min, and divide Add 200 g (0.73 mol) of 7-ACA in batches, and after dissolving, slowly raise the temperature to 40-45°C [reaction temperature in step 1] and react for 2.0-2.5 hours. After the reaction is completed, cool to -12~-15°C, add 40mL of concentrated hydrochloric acid and 50mL of water dropwise, continue to stir for 2.0~3.0h, filter, wash with acetonitrile-acetone mixture, the volume ratio of acetonitrile and acetone is 1:1, every 300 mL each time, and washed 3 times in total. Collect the solid, add 1000mL of acetone-water mixture, the volume ratio is 3:2, adjust the pH of the solution to 3.6-4.0 with sodium bicarbona...

Embodiment 2

[0053] Synthesis of intermediate I: Increase the amount of thiomethazolium to 152.4 g (1.31 mmol), and the others are the same as in Example 1, and the yield of intermediate I is 92.6%.

[0054] Synthesis of Intermediate II: Add 185g (0.94mol) of benzophenone hydrazone and 180mL of dichloromethane in turn to the reaction flask, stir to dissolve, control the temperature at 25-30°C, add 320g (3.08mol) of industrial grade Electrolytic MnO 2 , Reaction 1.0~2.0h. Filter, and wash the filter residue with dichloromethane (150 mL×3 times). Collect the filtrate and washing liquid, add 180g (0.55mol) of intermediate I, 180mL of dimethyl sulfoxide, stir and raise the temperature to 35-40°C [Reaction temperature in step 2] After reacting for 5-8h, lower the temperature below 30°C. Wash with 10% sodium chloride solution (1000mL×2), let stand to separate layers, evaporate the organic layer to dryness at 50-60°C, add 760mL ethyl acetate and 0.6mL triethylamine, stir at room temperature for...

Embodiment 3

[0059] Synthesis of Intermediate II: Add 185g (0.94mol) of benzophenone hydrazone and 180mL of dichloromethane in turn to the reaction flask, stir to dissolve, control the temperature at 20-25°C, add 320g (3.08mol) of industrial grade Electrolytic MnO 2 , Reaction 1.0~2.0h. Filter, and wash the filter residue with dichloromethane (150 mL×3). Collect the filtrate and washing liquid, add 180g (0.55mol) of intermediate I, 180mL of dimethyl sulfoxide, stir and raise the temperature to 50-60°C [Reaction temperature in step 2] After reacting for 5-8h, lower the temperature below 30°C. Wash with 10% sodium chloride solution (1000mL×2), let stand to separate layers, evaporate the organic layer to dryness at 50-60°C, add 760mL ethyl acetate and 0.4mL triethylamine, stir at room temperature for 12-15h, cool to 0°C, stirred for 2.0-3.0 h, filtered, washed with ethyl acetate, and dried to obtain Intermediate II as a light red solid with a yield of 90.1% and a liquid phase purity of 98.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com