Production process of air cushion

A production process and air cushion technology, which is applied in the field of air cushion production technology, can solve the problems of affecting the service life of the air cushion, the cushioning function, the small impact absorption effect, and the poor elasticity of the material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

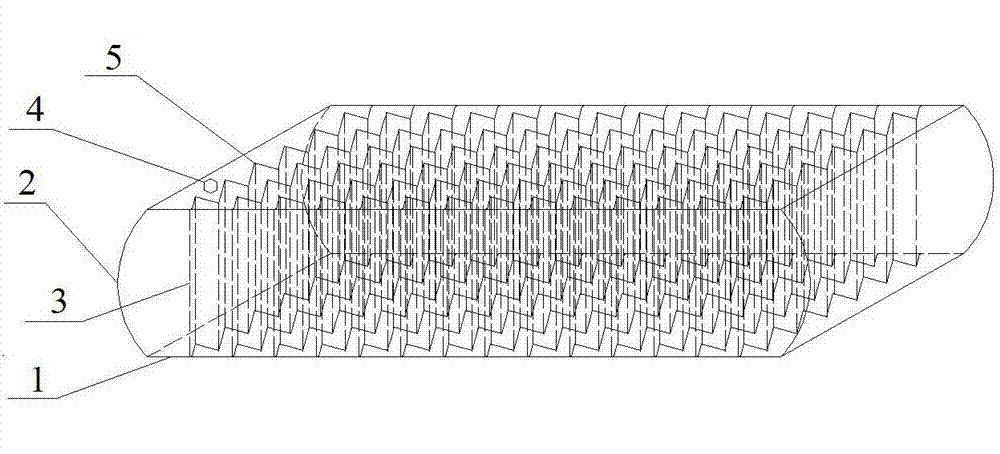

[0059] refer to figure 1 , a kind of production technique of air cushion, the concrete steps of described production technique are:

[0060] (1) Preparation of wire-drawn mesh 3: 300D polyester yarn is used as the raw material of the bottom yarn, and 420D polyester yarn is used as the raw material of wire-drawing, and it is prepared after warping, weaving on a double-needle bed warp knitting machine, and coiling;

[0061] Among them, when weaving by warp knitting machine, the drawing length, that is, the opening of the warp knitting machine is 8cm, and the W-shaped pattern is adopted; the deviation rate of polyester yarn linear density is less than or equal to 1.5%, the coefficient of variation of linear density is less than or equal to 0.50%, and the breaking strength is greater than or equal to 4.5%. cN / dtex, coefficient of variation of breaking strength is less than or equal to 3.0%, elongation at break is 28%, coefficient of variation of elongation at break is less than or...

Embodiment 2

[0074] refer to figure 1 , a production process of air cushion, the concrete steps of described production process are:

[0075] (1) Preparation of wire-drawn mesh 3: 300D polyester yarn is used as the raw material of the bottom yarn, and 420D polyester yarn is used as the raw material of wire-drawing, and it is prepared after warping, weaving on a double-needle bed warp knitting machine, and coiling;

[0076] Among them, when weaving by warp knitting machine, the drawing length, that is, the opening of the warp knitting machine is 8cm, and the W-shaped pattern is adopted; the deviation rate of polyester yarn linear density is less than or equal to 1.5%, the coefficient of variation of linear density is less than or equal to 0.50%, and the breaking strength is greater than or equal to 4.5%. cN / dtex, coefficient of variation of breaking strength is less than or equal to 3.0%, elongation at break is 28%, coefficient of variation of elongation at break is less than or equal to 9%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| coefficient of variation of linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com