Assembly and flame process for trunk bulkhead deck

A pyrotechnic and deck technology, applied in the field of ships, can solve problems such as low deck welding quality, and achieve the effects of small deformation, broad market space and high flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

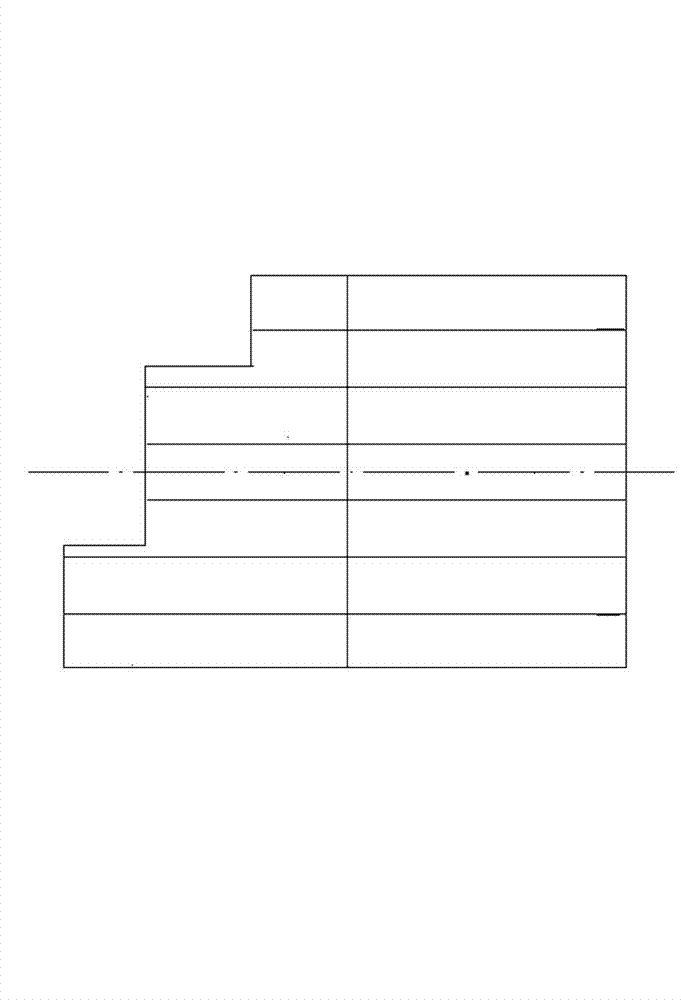

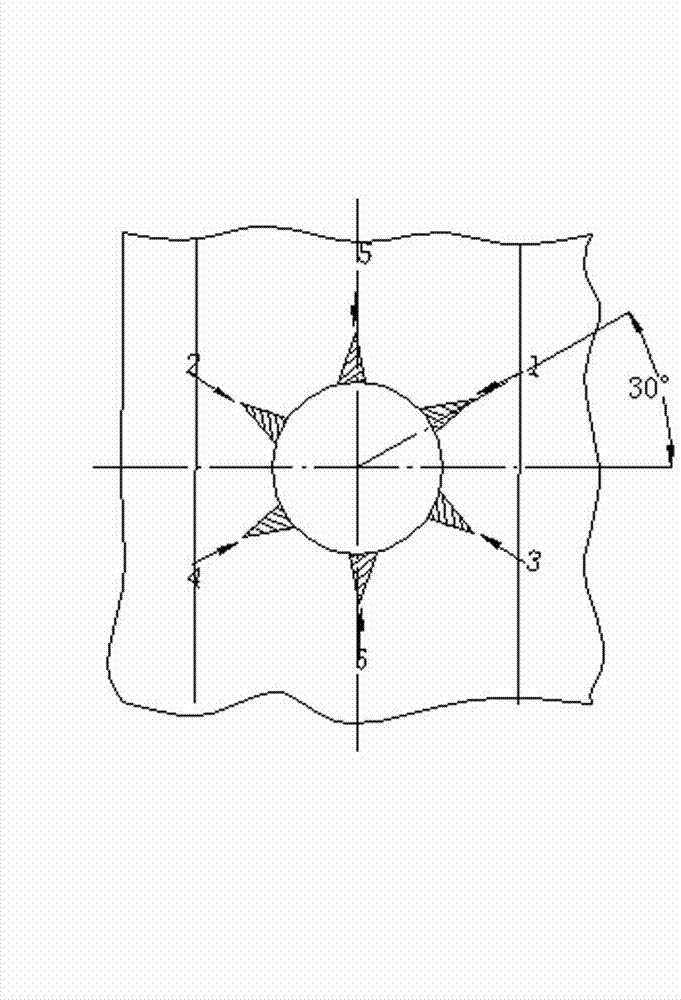

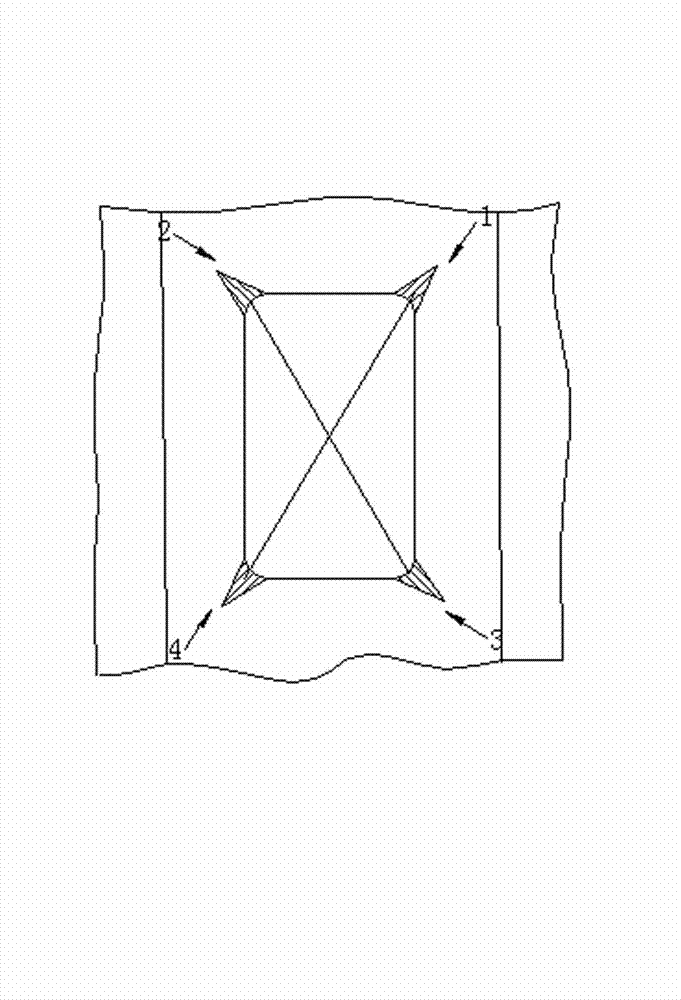

[0021] A wall deck assembly and pyrotechnics process, comprising the following steps:

[0022] A. Check and measure the flatness in advance before cutting the material. The uneven sheet should be flattened on the seven-star roller bed, and the error requirement is ±2 mm / m 2 , the splicing thin plate can not be used to ride on the welded steel plate, but to splice it with a wooden hammer with a long handle under the joint, and control the welding current. It should not be too large to avoid arc craters and ensure the surface quality of the thin plate;

[0023] B. Components on the thin-plate frame, such as deck beams, section steel and welded assemblies of wall stiffener components, such as angle steel, spherical flat steel, flat steel panels and double panels in ⊥-type composite materials, etc., are pre-supported in advance , Roll flat, maintain its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com